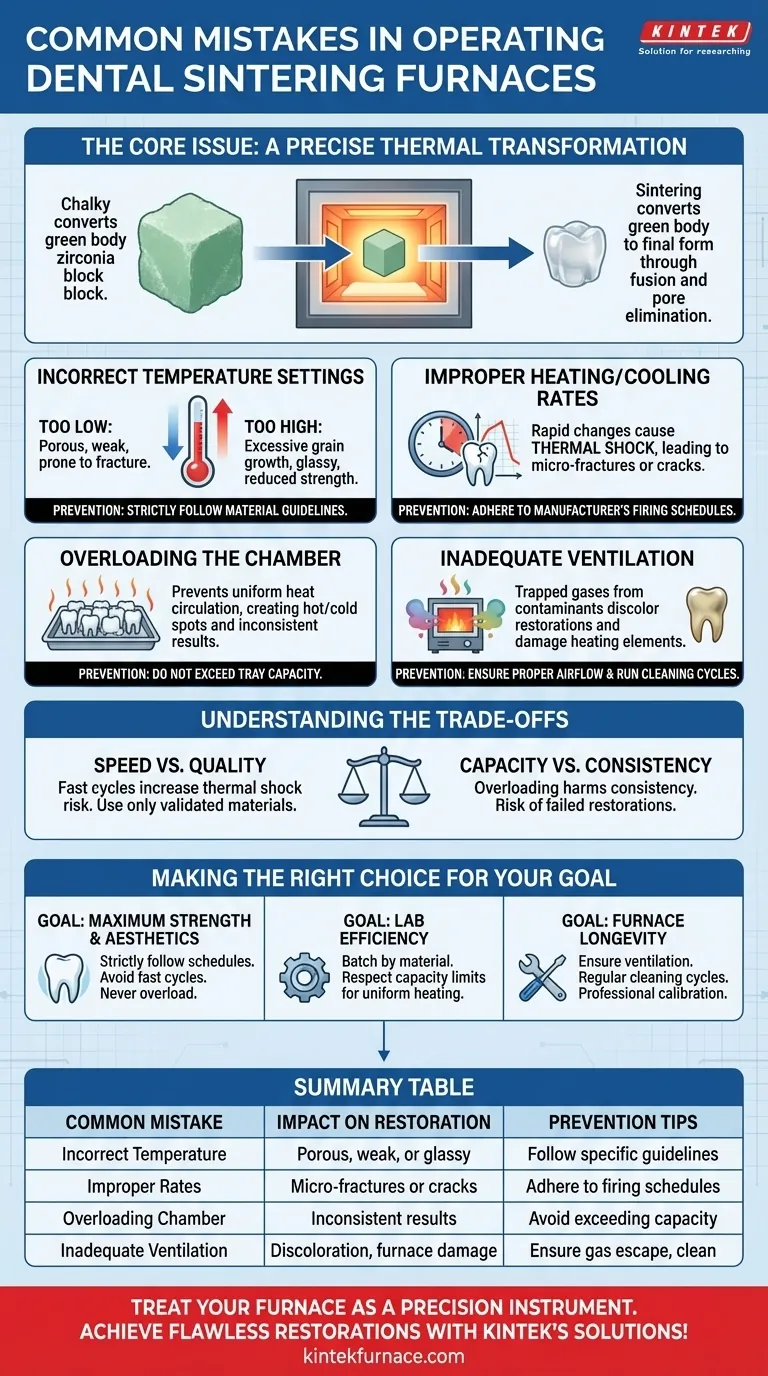

The most common mistakes when operating a dental sintering furnace are surprisingly easy to make and have significant consequences on the final restoration. These errors typically involve incorrect temperature settings, improper heating and cooling rates, overloading the sintering tray, and providing inadequate ventilation for the furnace.

The core issue is a misunderstanding of the underlying materials science. Sintering is not just a heating process; it is a precise thermal transformation where minor deviations in temperature, time, or atmosphere can compromise the strength, fit, and aesthetics of the final zirconia restoration.

The Science of Sintering: Why Precision is Non-Negotiable

Sintering is the critical process that converts a chalky, oversized zirconia "green body" into a dense, strong, and stable final restoration.

From Green State to Final Form

During the milling stage, the restoration is intentionally made larger to account for the shrinkage that occurs during sintering. The furnace heats this pre-sintered workpiece to a temperature just below its melting point.

The Transformation Process

At this peak temperature, the individual ceramic particles fuse, eliminating the pores between them. This densification process causes the material to shrink significantly while gaining its final properties, such as high flexural strength and desired translucency.

Analyzing Critical Sintering Errors

Every mistake introduces a variable that undermines the predictability of the outcome. Understanding the "why" behind each error is key to preventing it.

Incorrect Temperature Settings

The final sintering temperature is specific to the zirconia material being used. A temperature that is too low results in incomplete sintering, leaving the restoration porous, weak, and likely to fracture in clinical use. Conversely, a temperature that is too high can cause excessive grain growth, leading to reduced strength and a glassy, unnatural appearance.

Improper Heating and Cooling Rates

Zirconia is a ceramic and is therefore susceptible to thermal shock. Heating or, more critically, cooling the material too quickly introduces internal stresses that can cause micro-fractures or even catastrophic cracks. Always follow the material manufacturer's recommended firing schedule, as these rates are designed to manage thermal stress.

Overloading the Furnace Chamber

Placing too many restorations on the sintering tray is a false economy. Overloading prevents uniform heat circulation, creating hot and cold spots within the chamber. Restorations in the center may not reach the target temperature, resulting in under-sintering, while those on the edge may overheat. This leads to inconsistent and unpredictable results across the entire batch.

Inadequate Ventilation and Contamination

Sintering furnaces must have proper ventilation to allow gases to escape. Coloring liquids or other contaminants on the green body can release gases during heating. Without proper ventilation, these gases can deposit on the heating elements, shortening their lifespan, and can even discolor the restorations.

Understanding the Trade-offs

Decisions made in the sintering process often involve balancing speed, cost, and quality.

Speed vs. Quality

Many modern furnaces offer "speed" or "fast" sintering cycles that dramatically reduce processing time. While highly efficient, these cycles use aggressive heating and cooling rates that increase the risk of thermal shock. They should only be used with zirconia materials specifically validated for such cycles and in a well-calibrated furnace. The trade-off is time savings versus a potentially higher risk of compromised aesthetics or reduced strength.

Capacity vs. Consistency

Trying to maximize the number of units in a single cycle to save time and energy can directly harm consistency. A fully loaded tray almost guarantees temperature variations. The trade-off is lower per-unit run cost versus the much higher cost and reputational damage of a failed restoration or remake.

Making the Right Choice for Your Goal

To achieve predictable success, align your process with your primary objective.

- If your primary focus is maximum strength and aesthetics: Adhere strictly to the zirconia manufacturer's recommended cycle, avoid fast-sintering modes unless the material is specifically approved, and never overload the tray.

- If your primary focus is lab efficiency: Batch restorations by the same material type to run full cycles, but respect the furnace's capacity limits to ensure uniform heating.

- If your primary focus is furnace longevity: Ensure proper ventilation, run regular cleaning cycles to burn off contaminants, and have the furnace's temperature professionally calibrated at least once a year.

Ultimately, treating your sintering furnace as a precision instrument, not just an oven, is the foundation of high-quality, predictable restorations.

Summary Table:

| Common Mistake | Impact on Restoration | Prevention Tips |

|---|---|---|

| Incorrect Temperature Settings | Porous, weak, or glassy appearance | Follow manufacturer's specific temperature guidelines |

| Improper Heating/Cooling Rates | Micro-fractures or cracks from thermal shock | Adhere to recommended firing schedules |

| Overloading the Furnace Chamber | Inconsistent sintering and unpredictable results | Avoid exceeding tray capacity for uniform heat |

| Inadequate Ventilation | Discoloration and shortened furnace lifespan | Ensure proper gas escape and regular cleaning |

Achieve flawless zirconia restorations with KINTEK's precision sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide dental laboratories with advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met precisely, enhancing lab efficiency and restoration quality. Don't let common mistakes compromise your results—contact us today to discuss how our tailored furnace solutions can elevate your dental lab's performance!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures