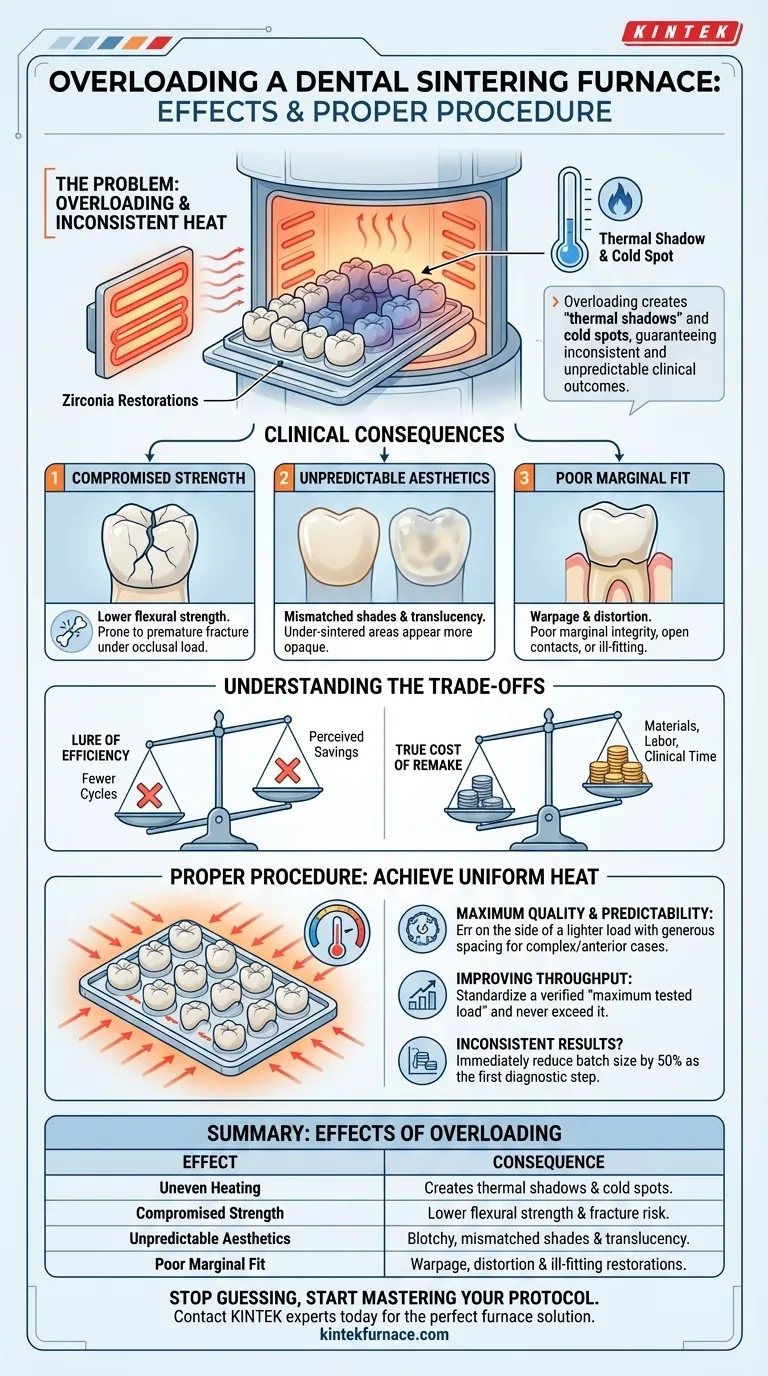

Overloading a dental sintering furnace directly causes uneven heating, which compromises the structural integrity, fit, and aesthetic quality of your final zirconia restorations. The core principle to avoid this is to ensure uniform radiant heat exposure to every surface of every unit in the chamber.

The central challenge is not simply fitting more units into the furnace, but rather managing the thermal dynamics of the chamber. Overloading creates "thermal shadows" and cold spots, guaranteeing inconsistent and unpredictable clinical outcomes.

The Core Problem: Inconsistent Heat Distribution

To understand the effects of overloading, you must first understand how a sintering furnace works. It doesn't heat the air like a convection oven; it uses powerful heating elements to radiate thermal energy directly onto the restorations.

How Radiant Heat Works

A sintering furnace functions on the principle of line-of-sight heat transfer. The heating elements glow and emit infrared radiation, which travels in a straight line and is absorbed by the surface of the zirconia, causing it to heat up and densify.

The "Thermal Shadow" Effect

When you place too many restorations too close together, they physically block each other from the heating elements. The units in the center of a tightly packed cluster are "shadowed" by the outer units, receiving significantly less radiant energy.

Creating Cold Spots

This shadowing effect creates temperature gradients, or cold spots, within the sintering tray. While the furnace's thermocouple might read the target temperature, the core of an overloaded batch can be dozens of degrees cooler, preventing the restorations within from reaching full sintering density.

The Clinical Consequences of Overloading

The lack of uniform heating caused by overloading directly translates into tangible, negative clinical outcomes that lead to costly remakes and a loss of confidence in your workflow.

Compromised Flexural Strength

This is the most critical failure. Zirconia that does not reach its prescribed final sintering temperature will not achieve its full density. This results in a restoration with significantly lower flexural strength, making it prone to premature fracture under occlusal load.

Unpredictable Aesthetics

Sintering temperature has a direct and profound impact on the final shade and translucency. Under-sintered areas will appear more opaque and lighter in value, leading to blotchy, mismatched crowns that do not meet the shade prescription.

Inaccurate Marginal Fit

The sintering process involves precise, uniform shrinkage of the zirconia material. When one part of a restoration gets hotter than another, it shrinks at a different rate, leading to warpage and distortion. This results in poor marginal integrity, open contacts, or a restoration that simply will not seat.

Understanding the Trade-offs

It's tempting to maximize each furnace cycle to save time and electricity, but this perspective is often counterproductive.

The Lure of "Efficiency"

Packing a furnace seems efficient on the surface. You run fewer cycles, which appears to save on energy consumption and technician time.

The True Cost of a Remake

This perceived efficiency evaporates with a single failed case. The cost of materials, labor, and, most importantly, the clinical chair time required for a remake far exceeds any minor savings gained by overloading the furnace. A predictable, successful outcome is always more efficient.

Making the Right Choice for Your Goal

The proper procedure isn't a magic number, but a principle: prioritize adequate spacing to allow for uniform heat circulation around every single unit.

- If your primary focus is maximum quality and predictability: Always err on the side of a lighter load with generous spacing (at least 1-2 mm) between each unit, especially for complex or aesthetic anterior cases.

- If your primary focus is improving throughput: Instead of overloading, standardize a "maximum tested load" for your specific furnace that you have verified produces consistent results, and never exceed it.

- If you are currently experiencing inconsistent results: Immediately reduce your batch size by 50% as the first diagnostic step to determine if overloading is the root cause of your issues.

Mastering your sintering protocol is a foundational element of a successful digital workflow.

Summary Table:

| Effect of Overloading | Consequence |

|---|---|

| Uneven Heating | Creates thermal shadows and cold spots within the chamber. |

| Compromised Strength | Leads to lower flexural strength and risk of fracture. |

| Unpredictable Aesthetics | Causes blotchy, mismatched shades and translucency. |

| Poor Marginal Fit | Results in warpage, distortion, and ill-fitting restorations. |

Achieve predictable, high-quality sintering results every time.

Overloading your furnace is a common but costly mistake that leads to remakes and disappointed patients. The key to success is consistent, uniform heating, which requires a furnace designed for precision and reliability.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, including lab high-temp furnaces, all customizable for unique needs. Our dental sintering furnaces are engineered to provide the uniform radiant heat essential for perfect zirconia densification, strength, and aesthetics.

Stop guessing and start mastering your sintering protocol. Contact our experts today to find the perfect furnace solution for your lab's workflow and ensure every restoration meets the highest standards.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations