Choosing a dental sintering furnace is a critical investment that directly impacts the quality of your restorations and the efficiency of your lab. The most important factors to consider are the furnace's temperature range and precision, its chamber capacity relative to your production volume, the quality of its heating elements, and the efficiency of its cooling system.

A sintering furnace is not just a piece of equipment; it is the heart of your ceramic restoration workflow. The right choice goes beyond a simple feature list to balance the specific material science of modern zirconia with your lab's unique production demands and long-term financial goals.

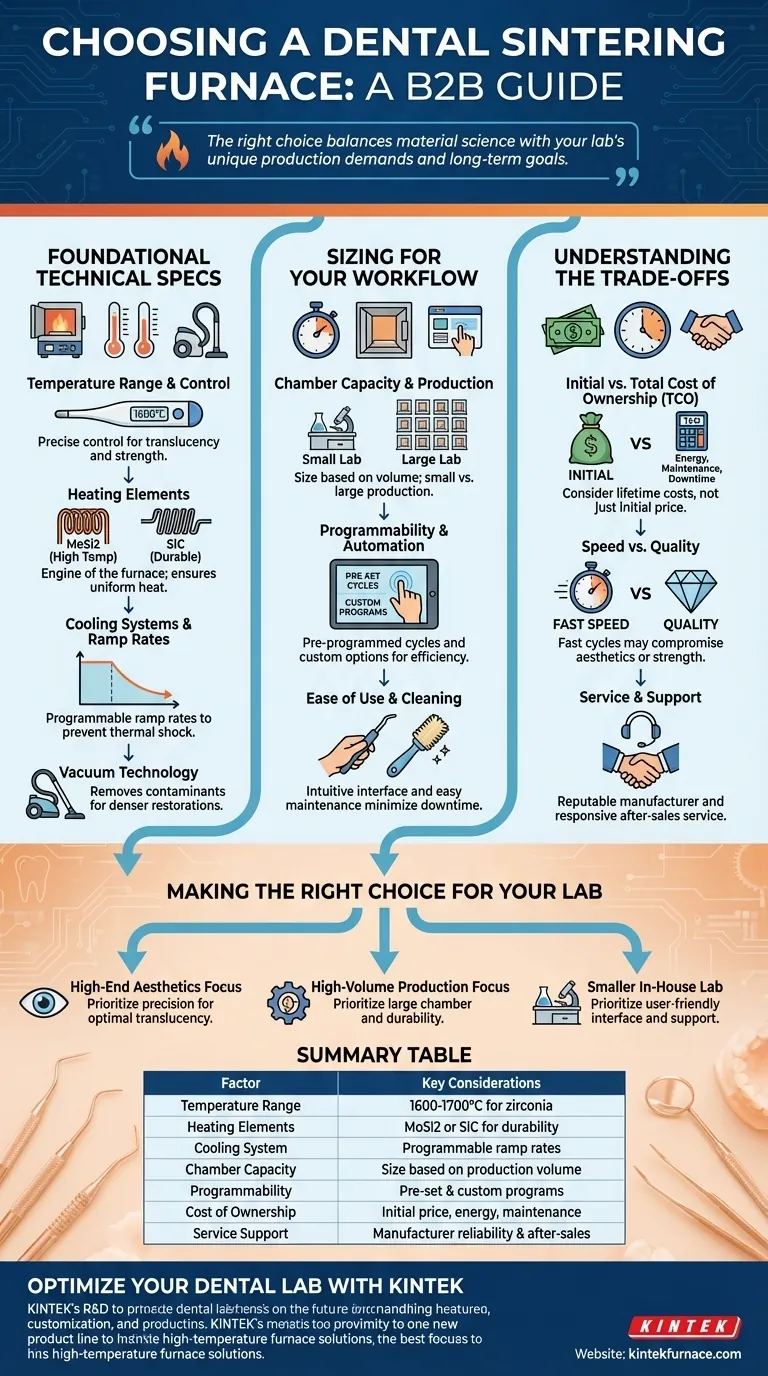

Foundational Technical Specifications

The core performance of a furnace is determined by its technical capabilities. These features directly influence the final strength, fit, and aesthetics of your dental restorations.

Temperature Range and Control

Sintering zirconia requires extremely high temperatures, typically between 1600°C and 1700°C. The furnace must be able to reliably reach and hold these temperatures.

More importantly, precise temperature control is non-negotiable. Even minor deviations can impact the translucency, shade, and structural integrity of the final restoration.

Heating Elements

The heating elements are the engine of the furnace. High-quality elements ensure accurate temperatures, uniform heat distribution, and a longer operational lifespan for the equipment.

Most modern furnaces use either Molybdenum Disilicide (MoSi2) or Silicon Carbide (SiC) elements. MoSi2 is known for its ability to perform at very high temperatures, while SiC is often praised for its durability and longevity.

Cooling Systems and Ramp Rates

How a furnace cools is just as important as how it heats. A rapid or uncontrolled cooling process can induce thermal shock, causing micro-fractures and weakening the restoration.

An efficient, programmable cooling system allows for a gradual temperature decrease, which is essential for minimizing defects and ensuring a durable, high-quality final product. The "ramp rate" refers to the speed at which temperature changes, and control over this is key.

Vacuum Technology

Some advanced furnaces incorporate vacuum technology. Pulling a vacuum during the sintering process can help remove atmospheric contaminants and ensure more uniform heat distribution.

This leads to a denser, more homogenous final material, which can improve the overall quality and consistency of your restorations.

Sizing for Your Workflow

Beyond the core technology, a furnace must fit seamlessly into your lab's operational flow. The right choice will enhance productivity, while the wrong one can create bottlenecks.

Chamber Capacity and Production Needs

The furnace's chamber size directly dictates its capacity. This decision should be based on your current and projected production volume.

A small, in-house lab may only need a furnace that can handle a few units at a time, whereas a large production laboratory requires a much larger chamber to maintain throughput.

Programmability and Automation

Modern furnaces often come with pre-programmed cycles tailored for specific materials from various manufacturers. This feature saves significant time and reduces the risk of human error.

Look for a furnace with a user-friendly interface that allows you to easily create, save, and select custom sintering programs to match your specific needs.

Ease of Use and Cleaning

A furnace with an intuitive user interface reduces training time for your staff. Likewise, a design that facilitates easy cleaning and routine maintenance helps minimize downtime and prolong the life of the unit.

Understanding the Trade-offs

A wise investment requires looking beyond the initial price tag and understanding the long-term implications of your choice.

Initial Cost vs. Total Cost of Ownership

A less expensive furnace may seem attractive, but it could have less durable heating elements or require more frequent maintenance. This leads to higher replacement costs and, more importantly, costly operational downtime.

Calculate the total cost of ownership, which includes the initial purchase, energy consumption, and the expected cost of service and replacement parts over the furnace's lifespan.

Speed vs. Quality

Many manufacturers advertise "fast" or "speed" sintering cycles. While these can dramatically increase throughput, they can sometimes compromise the aesthetic or structural properties of the zirconia if not executed properly.

Ensure the furnace is specifically designed and validated for speed sintering to avoid sacrificing the quality of your restorations for the sake of efficiency.

The Importance of Service and Support

Your furnace is a mission-critical asset. When it goes down, your production stops. Choose a reputable manufacturer known for reliable equipment and responsive after-sales service.

Good customer and technical support act as an insurance policy, ensuring you can resolve any issues quickly and get your lab back online.

Making the Right Choice for Your Lab

Your final decision should be guided by the specific goals and constraints of your practice or laboratory.

- If your primary focus is high-end aesthetics: Prioritize a furnace with exceptionally precise temperature and cooling control to achieve optimal translucency with advanced zirconia materials.

- If your primary focus is high-volume production: Prioritize a furnace with a large chamber, robust automation features, and durable heating elements to maximize throughput and minimize downtime.

- If you are a smaller in-house lab: Prioritize a furnace with a user-friendly interface, a library of pre-programmed cycles, and reliable customer support from the manufacturer.

By carefully evaluating these factors, you can select a sintering furnace that serves as a strategic asset for your business for years to come.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range | Must reach 1600-1700°C for zirconia sintering |

| Heating Elements | MoSi2 or SiC for durability and high-temperature performance |

| Cooling System | Programmable ramp rates to prevent thermal shock |

| Chamber Capacity | Size based on production volume (small to large labs) |

| Programmability | Pre-set cycles for materials, custom program options |

| Cost of Ownership | Initial price, energy use, maintenance, and downtime |

| Service Support | Manufacturer reliability and after-sales service |

Ready to optimize your dental lab with a reliable sintering furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you focus on high-end aesthetics or high-volume output, we ensure enhanced efficiency and quality. Contact us today to discuss how we can support your lab's success!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations