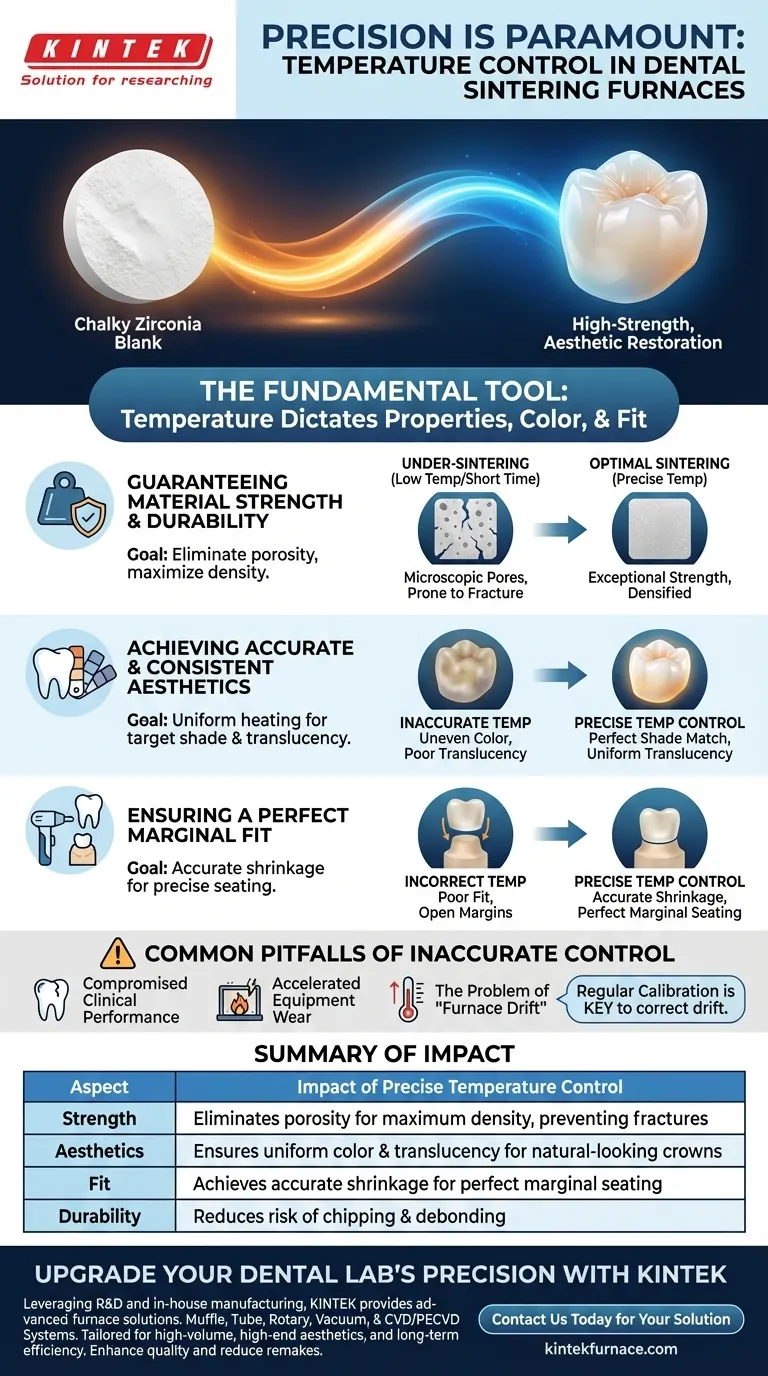

In dental technology, temperature is not just a setting; it is the fundamental tool that transforms a chalky zirconia blank into a high-strength, aesthetic restoration. Precise control over this temperature is crucial because it directly dictates the final physical properties, color, and fit of the crown or bridge. Without it, the entire process becomes unpredictable, resulting in restorations that are weak, discolored, or ill-fitting, leading to clinical failures and costly remakes.

Sintering is a delicate process of material transformation. Precise temperature control is the only variable that ensures this transformation happens correctly and repeatably, guaranteeing the final restoration meets the exact strength, aesthetic, and dimensional specifications required for clinical success.

How Temperature Precision Dictates Clinical Outcomes

The sintering process densifies the porous, pre-sintered zirconia by heating it to a specific temperature just below its melting point. This process is not about a single peak temperature but about the entire heating, holding, and cooling curve.

Guaranteeing Material Strength and Durability

The primary goal of sintering is to eliminate porosity and achieve maximum density. This density is what gives zirconia its exceptional strength.

If the temperature is too low or the hold time is too short (under-sintering), the material will not fully densify. This leaves microscopic pores that act as stress points, dramatically compromising the restoration's strength and making it prone to fracture under occlusal load.

Achieving Accurate and Consistent Aesthetics

The final shade and translucency of a zirconia restoration are highly dependent on the sintering cycle.

Precise temperature control ensures uniform heating throughout the material. This consistency is essential for achieving the target translucency and preventing blotchy or uneven color, ensuring the final crown perfectly matches the patient's natural dentition.

Ensuring a Perfect Marginal Fit

During sintering, zirconia shrinks by a predictable amount, typically around 20-25%. This shrinkage is factored into the initial oversized design of the restoration.

That shrinkage factor is directly tied to the sintering temperature. If the furnace temperature is inaccurate, the final shrinkage will be incorrect, resulting in a restoration that is either too large or too small. This leads to poor marginal fit, open margins, or restorations that simply will not seat.

Common Pitfalls of Inaccurate Control

Temperature inaccuracies, even minor ones, can have significant consequences for both the restoration and the furnace itself. Understanding these risks is critical for any dental lab.

Compromised Clinical Performance

The most immediate impact of poor temperature control is a faulty restoration. Deviations from the manufacturer's prescribed cycle can compromise the material's strength, durability, and adhesion capabilities.

This can lead to premature chipping, fractures, or debonding after the restoration has been placed, damaging the lab's reputation and requiring a complete remake.

Accelerated Equipment Wear

Inaccurate temperature control places undue stress on the furnace's internal components. Faulty temperatures can cause soiling and premature wear of heating elements, insulation, and temperature sensors (thermocouples).

This leads to more frequent and costly maintenance and can shorten the operational lifespan of the furnace.

The Problem of "Furnace Drift"

Over time, all furnaces experience "drift," where the displayed temperature no longer matches the actual temperature inside the chamber. This is a gradual process that can lead to a slow degradation of results.

Regular calibration is the only way to identify and correct this drift, ensuring your results remain consistent from the first restoration to the thousandth.

Making the Right Choice for Your Goal

When evaluating a sintering furnace, look beyond the price tag and focus on its ability to manage temperature. The precision of the furnace is a direct investment in the quality of your work.

- If your primary focus is high-volume production: Prioritize a furnace with proven temperature uniformity across the entire chamber to minimize inconsistent results and costly remakes.

- If your primary focus is high-end anterior aesthetics: Demand a furnace with exceptional temperature accuracy (e.g., ±1-2°C) and highly programmable cycles to precisely control translucency and shade.

- If your primary focus is long-term operational efficiency: Invest in a furnace with high-quality heating elements, reliable sensors, and a straightforward calibration process to ensure consistency and minimize downtime.

Ultimately, mastering temperature control is mastering the quality and predictability of your final restorations.

Summary Table:

| Aspect | Impact of Precise Temperature Control |

|---|---|

| Strength | Eliminates porosity for maximum density, preventing fractures |

| Aesthetics | Ensures uniform color and translucency for natural-looking crowns |

| Fit | Achieves accurate shrinkage for perfect marginal seating |

| Durability | Reduces risk of chipping and debonding in clinical use |

Upgrade Your Dental Lab's Precision with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on high-volume production, high-end aesthetics, or long-term efficiency, our furnaces deliver reliable temperature control to enhance your restoration quality and reduce remakes. Contact us today to discuss how we can tailor a solution for your needs!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations