Thermal continuity is non-negotiable. To successfully fill a sodium heat pipe, the entire system must be maintained at a high temperature to ensure the metallic sodium remains in a liquid state throughout the injection phase. This prevents the working fluid from condensing and solidifying within the pipelines, which would otherwise cause immediate blockages and process failure.

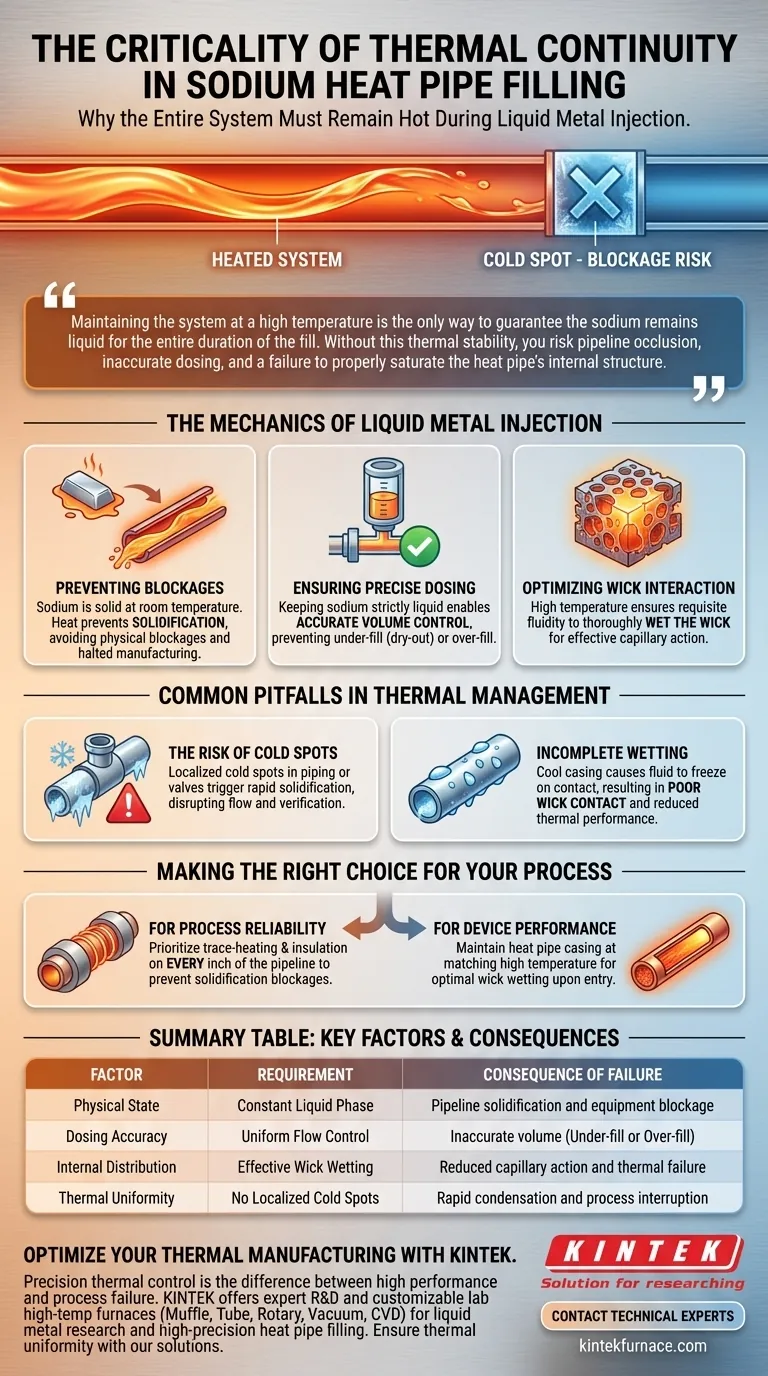

Maintaining the system at a high temperature is the only way to guarantee the sodium remains liquid for the entire duration of the fill. Without this thermal stability, you risk pipeline occlusion, inaccurate dosing, and a failure to properly saturate the heat pipe’s internal structure.

The Mechanics of Liquid Metal Injection

Preventing Pipeline Blockages

Sodium is a solid metal at room temperature and must be melted to be moved. The most immediate reason for maintaining high system temperatures is to prevent solidification.

If any part of the injection pipeline drops below the melting point, the sodium will condense and freeze. This creates physical blockages in the lines, halting the manufacturing process and potentially damaging the injection equipment.

Ensuring Precise Volume Control

High-performance heat pipes require a specific, calculated mass of working fluid. Precision is impossible if the fluid freezes in transit.

By keeping the sodium strictly in a liquid state, manufacturers can accurately measure and control the volume being injected. This ensures the heat pipe is neither under-filled (causing dry-out) nor over-filled (reducing thermal efficiency).

Optimizing Wick Interaction

Inside the heat pipe, the sodium must interact with a porous wick structure. The filling process is not just about moving fluid; it is about distribution.

Maintaining a high temperature ensures the sodium has the necessary fluidity to thoroughly wet the wick. This allows the working medium to penetrate and distribute evenly throughout the structure, which is essential for the capillary action that drives the heat pipe's operation.

Common Pitfalls in Thermal Management

The Risk of Cold Spots

A "high temperature" setting on a controller is not enough; the heat must be uniform. A common pitfall is allowing localized cold spots within the complex piping or valves.

Even a small section of uninsulated or under-heated pipe can trigger rapid solidification. This disruption halts the flow and makes it impossible to verify how much sodium actually entered the device.

Incomplete Wetting

If the heat pipe casing itself is cooler than the incoming liquid sodium, the fluid may solidify upon contact with the wall before it can settle into the wick.

This results in poor contact between the working fluid and the wick structure. Without proper wetting during the filling phase, the heat pipe will suffer from diminished thermal performance or complete operational failure.

Making the Right Choice for Your Process

To ensure a high-yield manufacturing process for sodium heat pipes, you must prioritize thermal uniformity.

- If your primary focus is Process Reliability: Ensure every inch of the injection pipeline is trace-heated and insulated to prevent blockages caused by solidification.

- If your primary focus is Device Performance: Maintain the heat pipe casing at a matching high temperature to ensure the sodium fully wets and penetrates the wick structure upon entry.

Thermal control during filling is the foundational step that determines whether the final device will function as a high-precision thermal conductor or a piece of scrap metal.

Summary Table:

| Factor | Requirement | Consequence of Failure |

|---|---|---|

| Physical State | Constant Liquid Phase | Pipeline solidification and equipment blockage |

| Dosing Accuracy | Uniform Flow Control | Inaccurate volume (Under-fill or Over-fill) |

| Internal Distribution | Effective Wick Wetting | Reduced capillary action and thermal failure |

| Thermal Uniformity | No Localized Cold Spots | Rapid condensation and process interruption |

Optimize Your Thermal Manufacturing with KINTEK

Precision thermal control is the difference between a high-performance heat pipe and process failure. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces designed to meet your unique engineering needs. Whether you are conducting liquid metal research or high-precision heat pipe filling, our solutions ensure the thermal uniformity you require.

Ready to elevate your thermal performance? Contact our technical experts today to find the perfect furnace for your application.

Visual Guide

References

- Shuaijie Sha, Junjie Wang. Experimental and numerical simulation study of sodium heat pipe with large aspect ratio. DOI: 10.2298/tsci231030059s

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the basic principle of a sintering furnace? Transform Powder into Dense, Strong Components

- Why are high frequencies used in induction heating? For Precise, Rapid Surface Heating

- What are the technical advantages of vacuum drying ovens for CeO2 separators? Protect Nanostructures & Boost Stability

- What is the function of a high-pressure hydrothermal reactor in graphene aerogel synthesis? Key to 3D Carbon Frameworks

- What are the advantages of using ultrasonic spray pyrolysis for metal powder? Achieve High Purity & Sphericity

- What is Joule Heating and how does it relate to induction heating? Master the Physics of Contactless Heating

- What is the function of a vacuum drying oven in SFRP processing? Preserve Material Integrity & Prevent Degradation