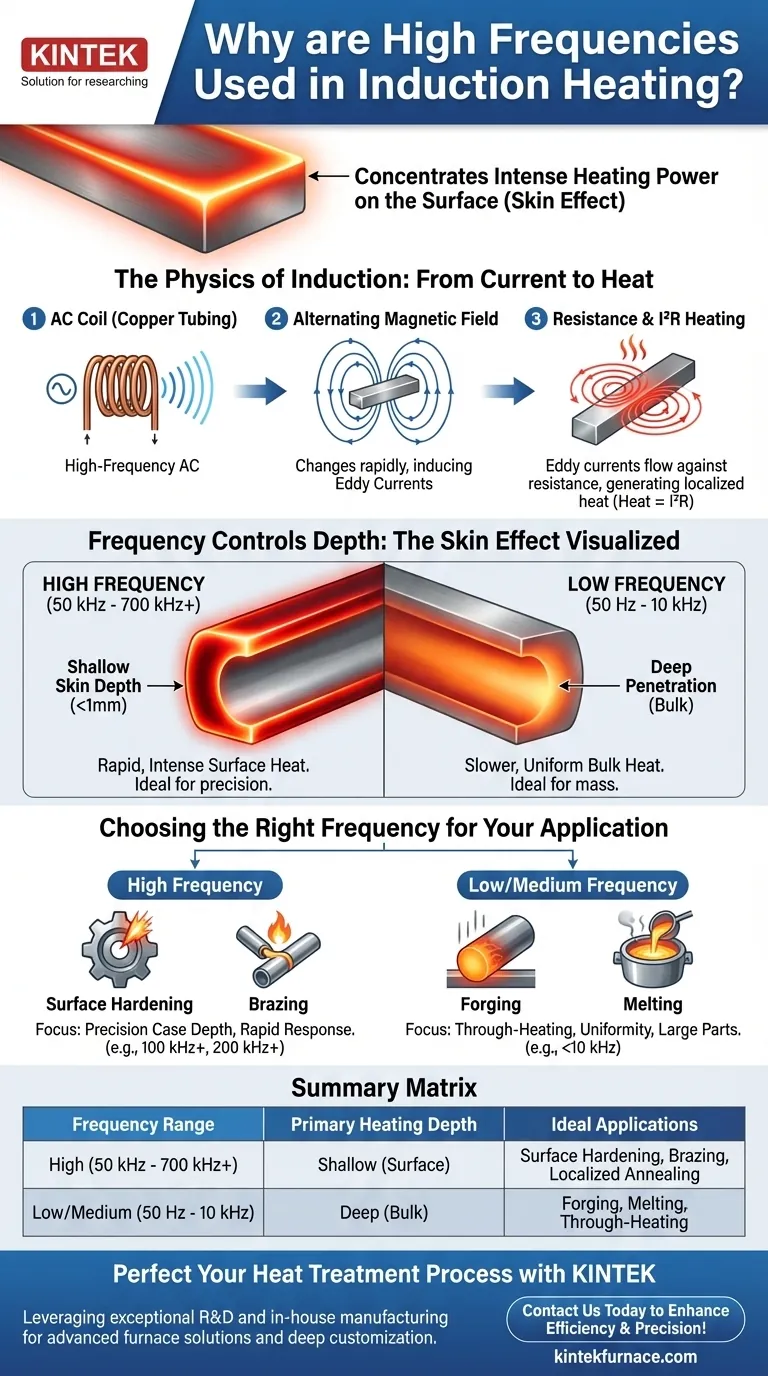

In short, high frequencies are used in induction heating to concentrate immense heating power onto the very surface of a metal part. This is achieved through a physical principle known as the "skin effect," where higher frequency currents are forced to flow in a thinner layer. This concentration results in extremely rapid, efficient, and precise heating, which is ideal for applications like surface hardening and brazing.

The core principle to understand is that frequency directly controls the depth of heating. High frequency means shallow, intense surface heat, while low frequency means deeper, slower, bulk heat. The choice is not about one being universally "better," but about selecting the right tool for a specific metallurgical goal.

The Physics of Induction: From Current to Heat

To understand the role of frequency, we must first review how induction heating works at a fundamental level. It's a non-contact process that turns a piece of metal into its own heating element.

The Alternating Magnetic Field

The process starts with an induction coil, typically made of copper tubing. A high-frequency alternating current (AC) is passed through this coil.

This AC generates a powerful and rapidly changing magnetic field in the space around and within the coil. The workpiece is placed within this field without ever touching the coil itself.

Inducing Eddy Currents

According to Faraday's Law of Induction, this changing magnetic field induces small, circular electrical currents within the conductive workpiece. These are known as eddy currents.

Resistance and I²R Heating

These eddy currents are not just flowing freely; they are flowing against the inherent electrical resistance of the metal. This opposition generates intense, localized heat according to the Joule heating principle (Heat = I²R).

It is the resistance to the flow of these induced eddy currents that actually heats the part.

Why Frequency is the Critical Control Parameter

While the principles above are constant, the frequency of the alternating current is the primary variable an engineer can adjust. This single parameter fundamentally changes the behavior and outcome of the process.

Introducing the Skin Effect

Alternating electrical currents do not flow uniformly through a conductor. They tend to concentrate on the outer surface, or "skin," of the material. This phenomenon is called the skin effect.

The strength of this effect is directly proportional to the frequency of the current.

The Relationship Between Frequency and Depth

As the frequency of the alternating current increases, the depth to which the eddy currents can penetrate decreases.

This effective depth is known as the skin depth or penetration depth. For many high-frequency induction applications (above 100 kHz), this depth can be less than a single millimeter.

Current Density and Heating Efficiency

The skin effect forces the induced current into a very small cross-sectional area. This dramatically increases the current density at the surface.

Because heating power is proportional to the square of the current (I²R), this massive increase in current density leads to extremely rapid and efficient heating, but only in that thin surface layer.

Understanding the Trade-offs

The decision to use a high or low frequency is a critical engineering trade-off based entirely on the desired outcome. There is no single "best" frequency.

The Case for High Frequency (50 kHz - 700 kHz+)

High frequencies are the standard choice for applications requiring precise surface heating. The shallow skin depth ensures that only the outer layer of the part gets hot, leaving the core cool and retaining its original properties.

This is ideal for surface hardening gears, brazing small joints, and annealing specific areas without affecting the rest of the component.

The Case for Low and Medium Frequency (50 Hz - 10 kHz)

When the goal is to heat the entire mass of a part, a lower frequency is required. Low-frequency magnetic fields penetrate much deeper into the metal.

This allows the eddy currents to flow through a larger volume, generating a slower, more uniform heat. This method, known as through-heating, is essential for applications like forging large billets or melting metals in a crucible.

The Equipment and Cost Factor

Generally, generating higher frequencies requires more sophisticated and expensive power supplies. The choice of frequency also impacts the design of the induction coil itself, adding another layer of practical consideration.

Choosing the Right Frequency for Your Application

Selecting the correct frequency is not an arbitrary choice; it is the most critical decision in designing an effective induction heating process.

- If your primary focus is surface hardening or precision case depth: Use a high frequency (100 kHz+) to create a shallow, concentrated heating zone.

- If your primary focus is through-heating a large part for forging: Use a low frequency (under 10 kHz) to ensure the heat penetrates deep into the core for uniformity.

- If your primary focus is heating small parts or thin-walled tubing: Use a very high frequency (200 kHz+) for a rapid response that heats the part quickly without overheating it.

Ultimately, frequency is the primary tool an engineer uses to tailor the induction heating process to the specific material and desired outcome.

Summary Table:

| Frequency Range | Primary Heating Depth | Ideal Applications |

|---|---|---|

| High (50 kHz - 700 kHz+) | Shallow (Surface) | Surface Hardening, Brazing, Localized Annealing |

| Low/Medium (50 Hz - 10 kHz) | Deep (Bulk) | Forging, Melting, Through-Heating |

Need to Perfect Your Heat Treatment Process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you require precise surface hardening or uniform bulk heating, our experts can help you select the right equipment for your specific metallurgical goals.

Contact us today to discuss how our solutions can enhance your lab's efficiency and precision!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What is the process of hot pressing? A Guide to Achieving Superior Material Density