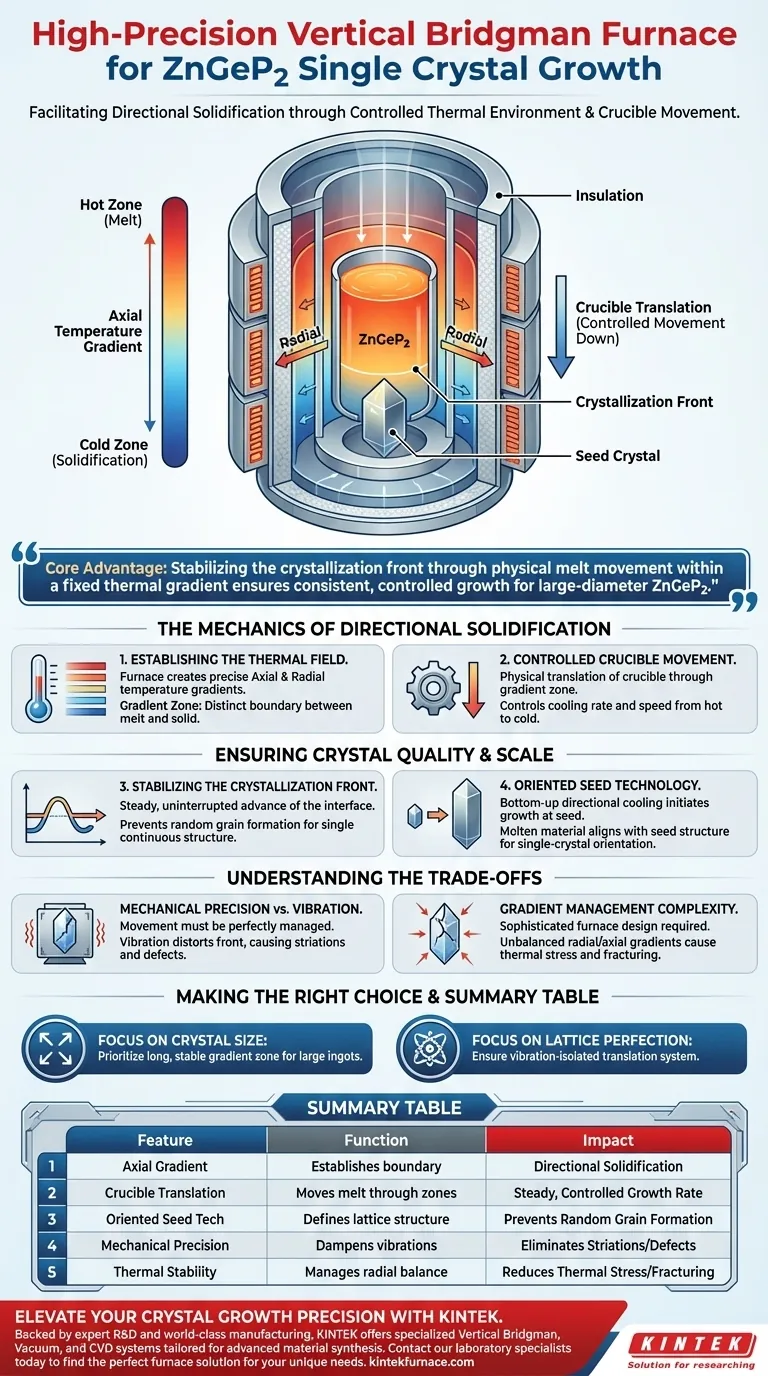

High-precision Vertical Bridgman Furnaces facilitate the growth of Zinc Germanium Phosphide (ZnGeP2) by strictly controlling the thermal environment to support directional solidification. This is achieved by establishing precise axial and radial temperature gradients and mechanically moving a crucible containing the melt through a specific gradient zone. This movement, combined with oriented seed crystal technology, forces crystallization to occur gradually from the bottom upward, resulting in large, high-quality single crystals.

The core advantage of this method is the stabilization of the crystallization front; by physically moving the melt through a fixed thermal gradient rather than simply lowering the furnace temperature, the system ensures a consistent and controlled growth rate essential for large-diameter ZnGeP2 formation.

The Mechanics of Directional Solidification

Establishing the Thermal Field

The foundation of the Vertical Bridgman process is the creation of a highly specific thermal environment.

The furnace does not heat the material uniformly; instead, it establishes precise axial and radial temperature gradients.

This "gradient zone" creates a distinct boundary between the liquid melt and the solidifying crystal.

Controlled Crucible Movement

Unlike batch processes where the entire furnace cools down simultaneously, the Vertical Bridgman method relies on physical translation.

The crucible containing the ZnGeP2 melt is mechanically lowered through the gradient zone.

This movement controls the cooling rate, forcing the material to pass from the hot zone to the cold zone at a precise speed.

Ensuring Crystal Quality and Scale

Stabilizing the Crystallization Front

For single crystal growth, the interface between liquid and solid (the crystallization front) must remain stable.

The high-precision nature of the furnace ensures that this front advances at a steady, uninterrupted rate.

This stability prevents the formation of random grains, ensuring the material solidifies as a single, continuous structure.

Oriented Seed Technology

To define the specific lattice structure of the ZnGeP2, this method utilizes oriented seed technology.

Because the cooling is directional (from the bottom upward), the growth initiates at the seed crystal located at the bottom of the crucible.

The molten material aligns itself with the seed's structure as it solidifies, propagating the single-crystal orientation throughout the entire large-sized ingot.

Understanding the Trade-offs

Mechanical Precision vs. Vibration

The reliance on moving the crucible introduces a mechanical variable that must be managed perfectly.

Any vibration or irregularity in the movement mechanism can disturb the crystallization front.

Even minor mechanical instabilities can induce striations or defects in the crystal lattice, negating the benefits of the thermal control.

Gradient Management Complexity

While axial and radial gradients allow for superior control, maintaining them requires sophisticated furnace design.

If the radial gradient (temperature difference from the center to the wall) is not perfectly balanced with the axial gradient (top to bottom), thermal stress can fracture the crystal during cooling.

Making the Right Choice for Your Goal

To maximize the quality of Zinc Germanium Phosphide growth, you must align the furnace capabilities with your specific output requirements.

- If your primary focus is Crystal Size: Prioritize a furnace with a long, stable gradient zone to allow for the extended growth cycles required for large-diameter ingots.

- If your primary focus is Lattice Perfection: Ensure the mechanical translation system is isolated from vibration to prevent physical disturbances at the crystallization front.

Mastering the synchronization between the crucible's translation speed and the furnace's temperature gradient is the definitive factor in producing high-quality ZnGeP2 single crystals.

Summary Table:

| Feature | Function in ZnGeP2 Growth | Impact on Crystal Quality |

|---|---|---|

| Axial Gradient | Establishes liquid-solid boundary | Facilitates directional solidification |

| Crucible Translation | Moves melt through thermal zones | Ensures a steady, controlled growth rate |

| Oriented Seed Tech | Defines lattice structure | Prevents random grain formation |

| Mechanical Precision | Dampens system vibrations | Eliminates lattice striations and defects |

| Thermal Stability | Manages radial temperature balance | Reduces thermal stress and crystal fracturing |

Elevate Your Crystal Growth Precision with KINTEK

Producing high-quality Zinc Germanium Phosphide requires more than just heat; it requires absolute control. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Vertical Bridgman, Vacuum, and CVD systems tailored for advanced semiconductor and optical material synthesis.

Whether you are scaling up for large-diameter ingots or focusing on lattice perfection, our customizable high-temperature lab furnaces provide the mechanical stability and thermal uniformity your research demands.

Ready to optimize your directional solidification process? Contact our laboratory specialists today to find the perfect furnace solution for your unique needs.

Visual Guide

References

- Alexey Lysenko, Alexey Olshukov. Band-like Inhomogeneity in Bulk ZnGeP2 Crystals, and Composition and Influence on Optical Properties. DOI: 10.3390/cryst15040382

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the impact of microwave power on the synthesis of 2D metal oxides? Master High-Speed Material Production

- Why are DEZ and GEME selected for Ge:ZnO ALD? Unlock Precise Atomic Doping and Thermal Stability

- Why are high frequencies used in induction heating? For Precise, Rapid Surface Heating

- What is the role of a forced convection oven in DPKB-S preparation? Optimize Biochar Synthesis and Material Purity

- What is the primary function of drying bovine horn biomass for PVC biocomposites? Optimize Material Strength

- How do elliptical mirrors function to create a horizontal temperature field in an optical Floating-Zone furnace?

- What advantages does a vacuum oven offer over a standard oven for V2CTx MXene films? Protect Your Material Quality

- Why is a precision electric heating reactor used for ozone treatment of porous graphene? Unlock Angstrom-Scale Accuracy