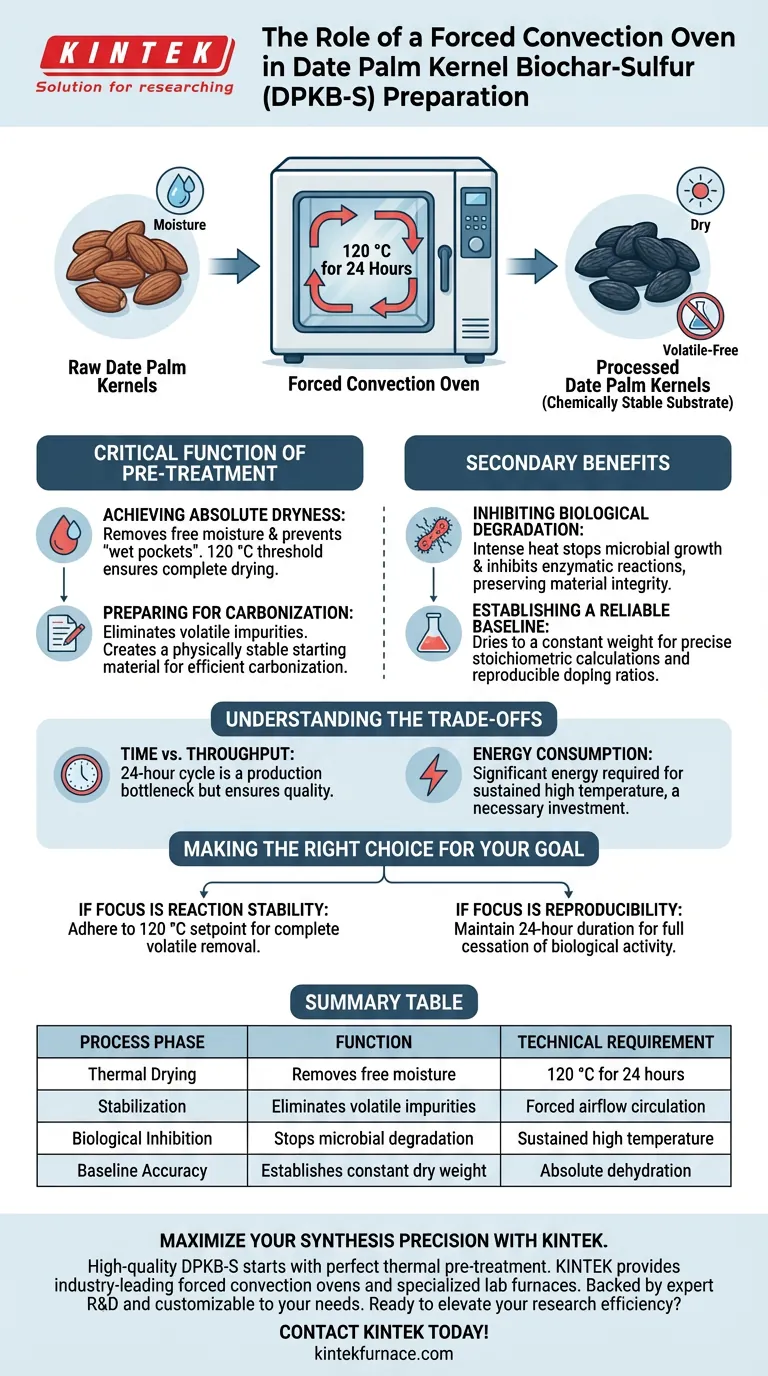

In the synthesis of Date Palm Kernel Biochar-Sulfur (DPKB-S), the forced convection oven acts as the foundational pre-treatment instrument. Its specific role is to subject washed date palm kernel raw materials to a sustained temperature of 120 °C for 24 hours. This rigorous thermal cycle is engineered to completely strip the biomass of moisture and volatile impurities, creating the necessary conditions for subsequent chemical processing.

The forced convection oven transforms raw, variable biomass into a chemically stable substrate. By eliminating free moisture and volatile compounds, it ensures the material is primed for effective chemical dehydration and high-quality carbonization.

The Critical Function of Pre-Treatment

Achieving Absolute Dryness

The primary objective of this phase is the removal of free moisture from the plant tissues. While standard plant analysis often utilizes lower temperatures (e.g., 60°C or 105°C), the preparation of DPKB-S requires a more aggressive threshold of 120 °C.

The forced convection mechanism ensures that heated air circulates evenly around the kernels. This continuous airflow guarantees that every part of the biomass reaches the target temperature, preventing "wet pockets" that could disrupt later stages.

Preparing for Carbonization

The oven does not merely dry the material; it stabilizes it. By removing water and volatile impurities early, the process ensures that the subsequent chemical dehydration and carbonization steps react only with the biomass structure itself.

If moisture were left in the kernels during carbonization, it would consume energy to evaporate, causing temperature fluctuations. This pre-treatment creates a physically stable starting material, ensuring the chemical reactions that follow are consistent and efficient.

Secondary Benefits of Thermal Processing

Inhibiting Biological Degradation

Raw plant materials are biologically active. The intense heat of the forced convection oven effectively stops microbial growth and inhibits enzymatic reactions.

Without this inhibition, the active components of the date palm kernels could degrade before synthesis is complete. This step preserves the structural integrity of the precursor material.

Establishing a Reliable Baseline

To synthesize biochar with precise doping ratios (like sulfur), you must know exactly how much dry matter you are starting with.

Moisture fluctuations can introduce significant experimental errors. By drying the material to a constant weight, the oven establishes a stable baseline weight, allowing for precise stoichiometric calculations in the DPKB-S synthesis.

Understanding the Trade-offs

Time vs. Throughput

The 24-hour drying cycle represents a significant bottleneck in production speed. While it ensures quality, it limits the throughput of the synthesis process compared to rapid-drying techniques like flash drying.

Energy Consumption

Maintaing a forced convection oven at 120 °C for a full day requires substantial energy.

This high energy cost is a necessary investment to prevent the failure of downstream processes. However, in large-scale production, this step is often the primary target for efficiency optimization.

Making the Right Choice for Your Goal

To ensure the successful preparation of DPKB-S, apply the following principles:

- If your primary focus is Reaction Stability: Strictly adhere to the 120 °C temperature setpoint to ensure all volatile impurities that could interfere with carbonization are removed.

- If your primary focus is Reproducibility: Do not shorten the 24-hour duration, as this guarantees the complete cessation of enzymatic activity and a consistent dry mass.

The forced convection oven is not just a drying tool; it is the gatekeeper of quality for the entire biochar synthesis workflow.

Summary Table:

| Process Phase | Function in DPKB-S Preparation | Technical Requirement |

|---|---|---|

| Thermal Drying | Removes free moisture and prevents "wet pockets" | 120 °C for 24 hours |

| Stabilization | Eliminates volatile impurities for consistent carbonization | Forced airflow circulation |

| Biological Inhibition | Stops microbial/enzymatic degradation of plant tissue | Sustained high temperature |

| Baseline Accuracy | Establishes constant dry weight for precise sulfur doping | Absolute dehydration |

Maximize Your Synthesis Precision with KINTEK

High-quality Date Palm Kernel Biochar-Sulfur starts with perfect thermal pre-treatment. KINTEK provides industry-leading forced convection ovens and specialized lab furnaces designed to maintain the rigorous temperature stability required for biomass processing.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are working on biochar research or advanced material carbonization, our equipment is fully customizable to meet your unique laboratory needs.

Ready to elevate your research efficiency? Contact KINTEK today to find the perfect thermal solution for your workflow!

Visual Guide

References

- Marwa R. Elkatory, Ahmed El Nemr. Fabrication of date palm kernel biochar-sulfur (DPKB-S) for super adsorption of methylene blue dye from water. DOI: 10.1038/s41598-024-56939-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What functions do high-strength graphite molds perform during SPS? Drive Efficiency & Precision in Material Bonding

- What is the primary function of the low-temperature pyrolysis process? Ensure Safe Battery Recycling with Pretreatment

- How does a high-precision laboratory oven ensure the performance of large-scale halide perovskite catalyst plates?

- What is the primary value of using a thermal simulator for weather-resistant steel? Precision Hot Working Modeling

- Why is temperature gradient management necessary for high-temperature impedance measurements? Master Thermal Precision

- What role does an industrial box-type resistance furnace play in phosphor conversion? Powering Material Synthesis

- Why is vacuum sealing technology essential for K2In2As3 synthesis? Master High-Purity Solid-State Reactions

- What is the use of a laboratory furnace? Unlock Precise Material Transformation