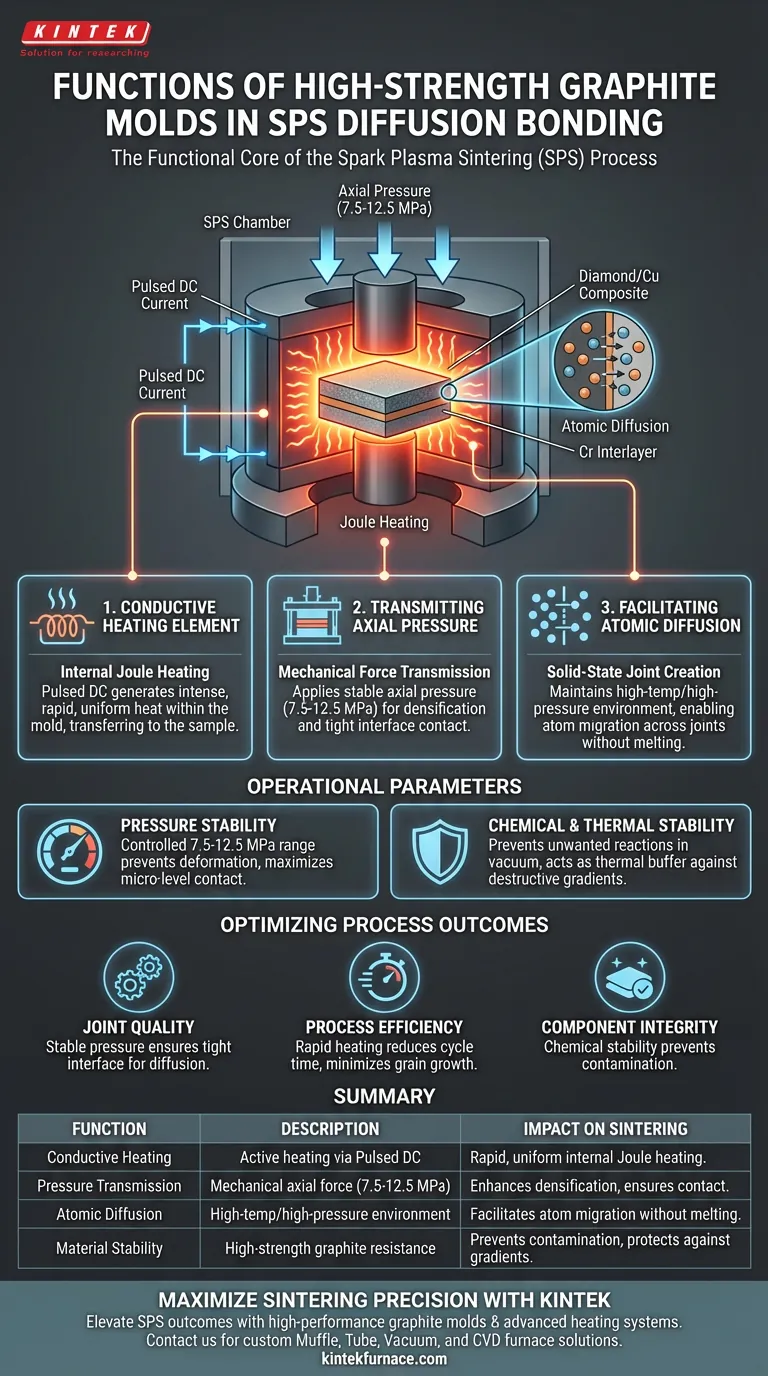

High-strength graphite molds serve as the functional core of the Spark Plasma Sintering (SPS) process. They act simultaneously as the sample containment vessel, the primary conductive heating element, and the mechanical medium for transmitting critical axial pressure to the workpiece.

In the SPS environment, the graphite mold is not merely a passive container; it is an active component that synchronizes electrical heating with mechanical compression to force atomic diffusion at the material interface.

The Triple Function of the Graphite Mold

Acting as a Conductive Heating Element

In SPS, heat is not applied externally; it is generated internally. The graphite mold is electrically conductive, allowing pulsed direct current (DC) to pass through it.

This flow of electricity generates intense Joule heating directly within the mold walls. Because of the graphite's high thermal conductivity, this thermal energy is transferred rapidly and uniformly to the internal sample, such as a Diamond/Cu composite.

Transmitting Axial Pressure

Simultaneous to heating, the mold serves as the transmission vehicle for mechanical force. Working with a pressurization system, the mold applies stable axial pressure—specifically between 7.5 and 12.5 MPa in Diamond/Cu and Chromium (Cr) applications—to the assembly.

This pressure is vital for densification. It mechanically forces the materials together, breaking down surface irregularities to ensure tight interface contact.

Facilitating Atomic Diffusion

The ultimate goal of combining heat and pressure is to drive atomic diffusion. By maintaining the sample in a contained, high-pressure, high-temperature environment, the mold enables atoms to migrate across the joint interface.

This creates high-quality, solid-state joints between dissimilar materials, such as the Diamond/Cu composite and the Cr interlayer, without melting the bulk material.

Understanding the Operational Parameters

Pressure Stability

While high-purity graphite can withstand pressures exceeding 20 MPa, the specific SPS process for Diamond/Cu composites relies on a controlled range of 7.5 to 12.5 MPa.

Operating within this specific window prevents mold deformation while ensuring enough force is applied to maximize contact area at the micro-level.

Chemical and Thermal Stability

The mold must maintain structural integrity in harsh environments. High-strength graphite provides chemical stability, preventing unwanted reactions with the sample materials in a vacuum environment.

It also acts as a thermal buffer, ensuring that the rapid heating rates characteristic of SPS do not create destructive thermal gradients within the sample.

Optimizing Process Outcomes

If your primary focus is Joint Quality: Ensure the mold is capable of maintaining stable pressure between 7.5 and 12.5 MPa to guarantee the tight interface contact required for atomic diffusion.

If your primary focus is Process Efficiency: Leverage the graphite's electrical and thermal conductivity to achieve rapid heating rates, reducing overall cycle time while minimizing grain growth.

If your primary focus is Component Integrity: Rely on the chemical stability of high-purity graphite to prevent contamination of sensitive materials like Diamond/Cu composites during high-temperature sintering.

The success of the SPS diffusion bonding process relies entirely on the graphite mold's ability to balance electrical conductivity with mechanical rigidity.

Summary Table:

| Function | Description | Impact on Sintering |

|---|---|---|

| Conductive Heating | Acts as an active heating element via Pulsed DC | Enables rapid, internal Joule heating for uniform thermal energy. |

| Pressure Transmission | Mechanically transmits axial force (7.5 - 12.5 MPa) | Enhances densification and ensures tight interface contact. |

| Atomic Diffusion | Maintains high-temp/high-pressure environment | Facilitates atom migration across joints without melting bulk material. |

| Material Stability | High-strength graphite provides chemical/thermal resistance | Prevents contamination and protects against destructive thermal gradients. |

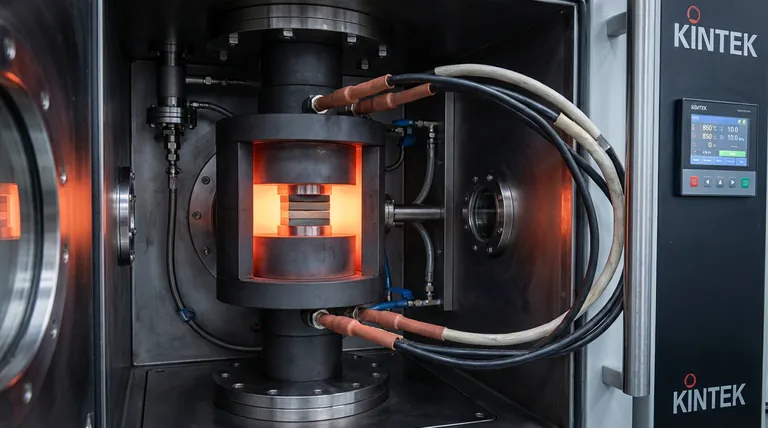

Maximize Your Sintering Precision with KINTEK

Elevate your Spark Plasma Sintering (SPS) outcomes with high-performance graphite molds and advanced heating systems. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique materials research and industrial needs. Whether you are working on Diamond/Cu composites or complex diffusion bonding, our solutions ensure stable pressure control and optimal thermal conductivity.

Ready to optimize your lab's efficiency? Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- Ying Zhou, Degan Xiong. An Investigation on the Spark Plasma Sintering Diffusion Bonding of Diamond/Cu Composites with a Cr Interlayer. DOI: 10.3390/ma17246026

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why must raw kaolin undergo heat treatment for DLP 3D printing? Control Viscosity for Precision Printing

- What is the disadvantage of dental ceramic? Weighing Cost, Strength, and Aesthetics

- What type of furnaces are commonly used for sintering? Choose the Right Furnace for Your Process

- What is the function of a laboratory hot air drying oven in TiO2 treatment? Ensure Uniform Nanoparticle Quality

- Why must the casting dispersion be treated in a 100°C drying oven? Ensure Perfect Film Morphology

- What is the technical necessity of using a laboratory vacuum drying oven for Cu-Fe-N-C catalyst precursors?

- Why is calcination at 700 °C necessary for extracted diatomaceous biosilica? Achieve Peak Material Stability

- What is the significance of an ultra-low pressure vacuum system in PS-PVD? Unlock Superior Vapor-Phase Coating