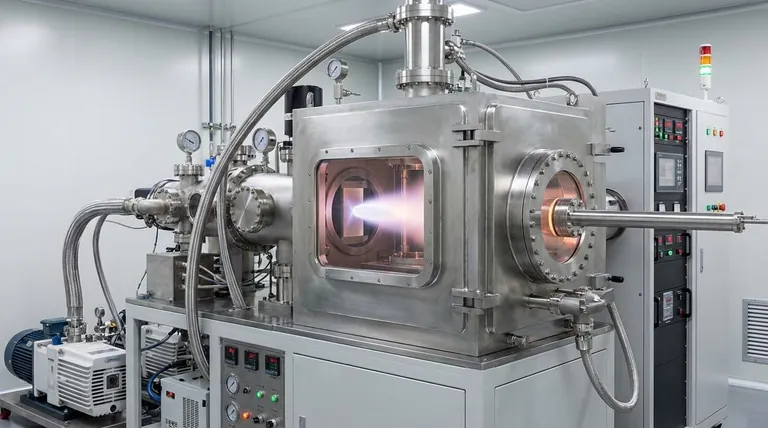

The ultra-low pressure vacuum system is the defining architecture of the Plasma Spray-Physical Vapor Deposition (PS-PVD) process. By maintaining a specific vacuum range between 50 and 300 Pa, this system forces the plasma jet to expand at supersonic speeds. This expansion fundamentally alters the state of the spraying materials, allowing them to be transported as gas phases or nano-clusters rather than traditional liquid droplets.

By creating a rarefied environment, the vacuum system transforms the deposition process from a standard spray into a vapor-phase transport mechanism. This allows for the growth of unique columnar structures that provide superior thermal insulation, even on complex, shadowed surfaces.

The Physics of Low-Pressure Deposition

Achieving Supersonic Plasma Expansion

The core function of the vacuum system is to lower the ambient pressure to a critical window of 50 to 300 Pa.

In this ultra-low pressure environment, the plasma jet is no longer confined by atmospheric resistance. It expands rapidly, achieving supersonic velocities that are impossible in standard atmospheric plasma spraying.

Transformation of Material State

This supersonic expansion changes the physical state of the coating material.

Instead of hitting the substrate as heavy liquid droplets, the material is vaporized or broken down into nano-clusters. This enables the transport of coating materials over long distances while maintaining high energy.

Structural and Functional Outcomes

Growth of Unique Microstructures

The vapor-phase transport enabled by the vacuum system dictates how the coating solidifies.

The material condenses on the substrate to form unique columnar or quasi-columnar structures. This specific microstructure is highly desirable because it significantly reduces the thermal conductivity of the final coating.

Non-Line-of-Sight Capabilities

Standard thermal sprays require a direct line of sight to the surface being coated.

However, because the PS-PVD process transports material in a gas phase, it behaves more like a cloud than a spray gun. This allows the coating to penetrate shadowed areas and cover complex geometries that are not in the direct line of sight.

Understanding the Process Constraints

The Necessity of Pressure Precision

While the low pressure enables advanced properties, it introduces a strict process constraint.

The system relies entirely on maintaining the specific 50 to 300 Pa range. Deviating from this pressure window risks failing to achieve the required supersonic expansion, which would revert the material transport back to a less effective state and compromise the formation of the desired columnar structure.

Making the Right Choice for Your Goal

To maximize the benefits of PS-PVD, consider your specific coating requirements:

- If your primary focus is complex geometry: Leverage the vacuum system's ability to transport gas-phase material to coat components with hidden or shadowed surfaces (non-line-of-sight).

- If your primary focus is thermal insulation: Rely on the vacuum-enabled columnar structure to achieve the lowest possible thermal conductivity for your barrier coatings.

The ultra-low pressure environment is not just an operational setting; it is the fundamental mechanism that unlocks the advanced material properties of PS-PVD.

Summary Table:

| Feature | PS-PVD (Ultra-Low Pressure) | Standard Atmospheric Spray |

|---|---|---|

| Pressure Range | 50 - 300 Pa | Atmospheric Pressure |

| Material State | Vapor phase / Nano-clusters | Liquid droplets |

| Jet Velocity | Supersonic expansion | Subsonic flow |

| Microstructure | Columnar (Low thermal conductivity) | Splat / Layered structure |

| Coverage Type | Non-line-of-sight (Gas-like behavior) | Direct line-of-sight only |

Optimize Your Advanced Coating Processes with KINTEK

Achieving the precise 50-300 Pa range required for PS-PVD demands high-performance vacuum architecture. KINTEK provides industry-leading high-temperature vacuum systems and specialized furnaces tailored for demanding R&D and industrial manufacturing.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your unique thermal processing and coating needs. Our team helps you achieve the precise environments necessary for superior material transformation and thermal insulation.

Ready to elevate your material science capabilities? Contact us today to discuss your custom furnace requirements.

References

- He Qin, Xiaoming You. Investigation of the Interface Diffusion Layer’s Impact on the Thermal Cycle Life of PS-PVD Thermal Barrier Coatings. DOI: 10.3390/coatings15010013

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Why is precise molar measurement of metal nitrates required during the preparation of high-entropy oxide precursor solutions? Ensure HEO Stability & Purity

- How does the extended isothermal calcination in a furnace contribute to crystalline quality? Boost Material Purity

- What are the advantages of zirconia crowns? Achieve Durable, Aesthetic, and Biocompatible Dental Restorations

- Why is a graphite furnace better than a flame in AAS? Unlock Trace-Level Detection for Your Lab

- What mechanisms generate heat in induction heating? Discover the Science of Efficient Material Processing

- Why are corrosion-resistant materials necessary for gasification systems processing PET or PVC? Ensure System Safety

- What is the purpose of silver paste coating for BCZT ceramics? Ensuring Precision in Electrical Performance Testing

- How does the thermal field length impact YAG fiber dip coatings? Achieve Uniform, Bead-Free Films