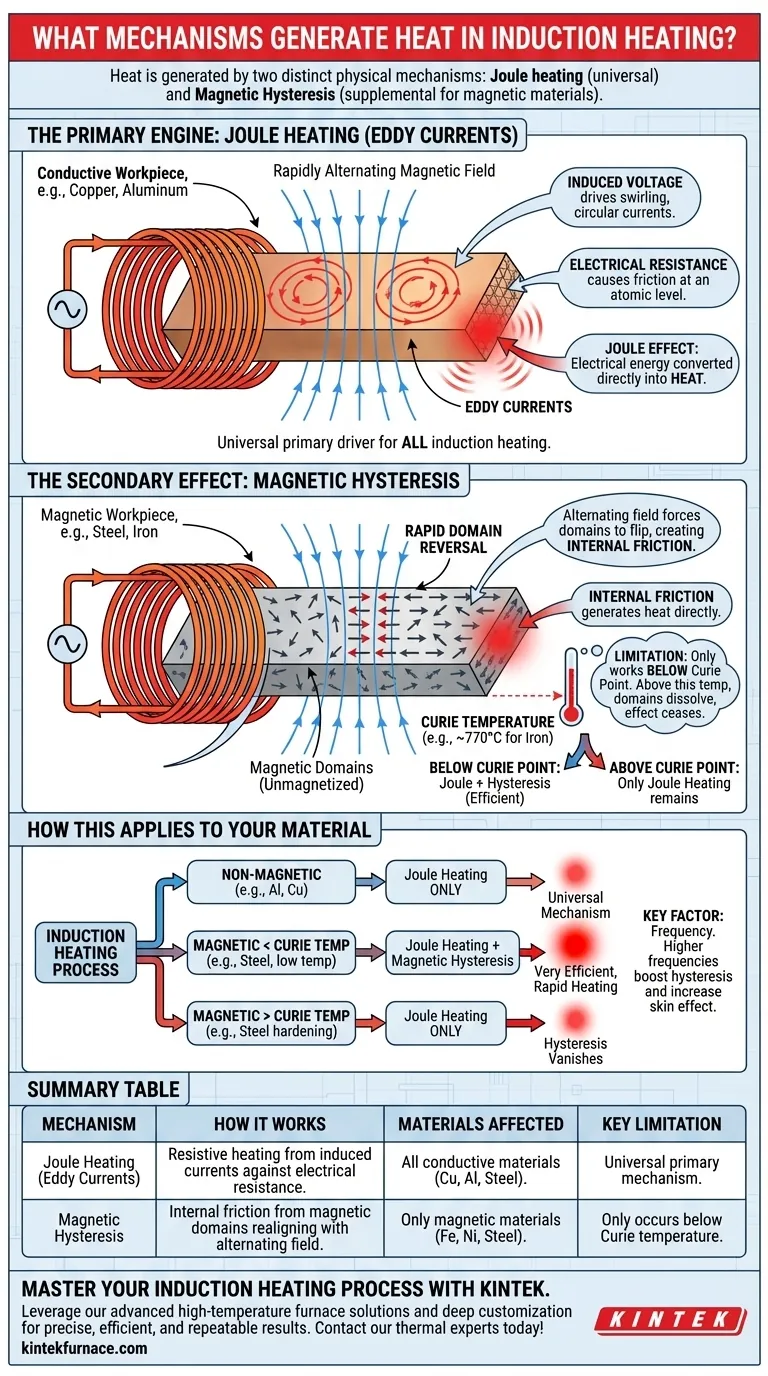

In induction heating, heat is generated within a material by two distinct physical mechanisms: Joule heating caused by induced electrical currents and magnetic hysteresis losses in magnetic materials. Joule heating is the universal and primary driver, while hysteresis provides a supplemental heating effect that is only present in specific materials under certain conditions.

The core principle to understand is that all induction heating relies on Joule heating from eddy currents. Magnetic hysteresis is an additional, secondary effect that accelerates heating but only occurs in magnetic metals below a specific temperature threshold.

The Primary Engine: Joule Heating (Eddy Currents)

The foundational mechanism for all induction heating is Joule heating, also known as resistive heating. This process is identical to how a simple electric stove burner gets hot, but the currents are induced without any physical contact.

How Eddy Currents Are Formed

An induction heater's coil generates a strong, rapidly alternating magnetic field. When a conductive workpiece (like a piece of metal) is placed within this field, the changing magnetic flux induces a voltage within the part, according to Faraday's Law of Induction.

From Voltage to Current

This induced voltage drives swirling, circular currents within the material. These are known as eddy currents, named for their similarity to whirlpools or eddies in a fluid.

The Role of Resistance

As these eddy currents flow through the workpiece, they encounter the material's natural electrical resistance. This resistance to the flow of electrons causes friction at an atomic level, converting electrical energy directly into heat. This conversion is the Joule effect.

The Secondary Effect: Magnetic Hysteresis

For a specific subset of materials—namely, magnetic metals like iron, nickel, and certain steels—a second heating mechanism comes into play.

What Are Magnetic Domains?

Magnetic materials are composed of countless microscopic regions called magnetic domains, each acting like a tiny, permanent magnet. In an unmagnetized state, these domains are randomly oriented, canceling each other out.

The Friction of Reversal

When the alternating magnetic field from the induction coil penetrates the material, it forces these magnetic domains to rapidly align and realign with the field's changing polarity. This constant, high-frequency flipping creates significant internal friction between the domains.

This internal friction generates heat directly. You can visualize this by rapidly bending a paperclip back and forth; the metal heats up due to the internal stress and friction, and hysteresis operates on a similar principle at a magnetic level.

The Curie Point Limitation

Hysteresis heating has a critical limitation: it only works below the material's Curie temperature. Above this specific temperature (around 770°C or 1420°F for iron), the material loses its magnetic properties. The domains dissolve, and the hysteresis effect ceases entirely, leaving only Joule heating to continue the process.

Understanding the Key Factors

The efficiency and behavior of an induction heating process depend on which of these mechanisms is active and dominant.

Joule Heating: The Universal Contributor

Joule heating from eddy currents occurs in any electrically conductive material, whether it is magnetic or not. It is the sole heating mechanism for materials like copper, aluminum, and brass. For magnetic materials heated past their Curie point, it is also the only mechanism at work.

Hysteresis: The Low-Temperature Assistant

Hysteresis contributes a significant amount of heat only in magnetic materials and only below the Curie temperature. In these applications, it acts as a powerful assistant, allowing for very rapid initial heating. However, its contribution disappears once the material becomes non-magnetic.

The Impact of Frequency

The frequency of the alternating magnetic field is a critical parameter. Higher frequencies increase the rate of magnetic reversals, boosting hysteresis heating. They also cause the eddy currents to concentrate near the surface of the part (an effect known as the skin effect), which can focus the Joule heating in a smaller area.

How This Applies to Your Material

Your approach to induction heating is dictated entirely by the properties of the material you are working with.

- If your primary focus is heating non-magnetic materials (like aluminum or copper): Your process is governed exclusively by Joule heating from eddy currents.

- If your primary focus is heating magnetic materials (like steel) to lower temperatures: You will benefit from the combined power of both Joule heating and magnetic hysteresis, resulting in very efficient heating.

- If your primary focus is heating magnetic materials through their Curie point (e.g., for hardening steel): Be prepared for a potential change in the heating rate as the supplemental effect of hysteresis vanishes.

Understanding these two distinct yet complementary mechanisms is the key to mastering and optimizing any induction heating process.

Summary Table:

| Mechanism | How It Works | Materials Affected | Key Limitation |

|---|---|---|---|

| Joule Heating (Eddy Currents) | Resistive heating from induced currents flowing against material's electrical resistance. | All conductive materials (e.g., copper, aluminum, steel). | Universal primary mechanism. |

| Magnetic Hysteresis | Internal friction from magnetic domains realigning with the alternating field. | Only magnetic materials (e.g., iron, nickel, steel). | Only occurs below the material's Curie temperature. |

Master Your Induction Heating Process with KINTEK

Understanding the precise mechanisms of Joule heating and magnetic hysteresis is the first step to optimizing your thermal processing. Whether you are working with non-magnetic materials like aluminum or magnetic steels for hardening, the right equipment is critical for control and efficiency.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let us help you achieve precise, efficient, and repeatable results. Contact our thermal experts today to discuss how our solutions can be tailored to your specific material and process needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability