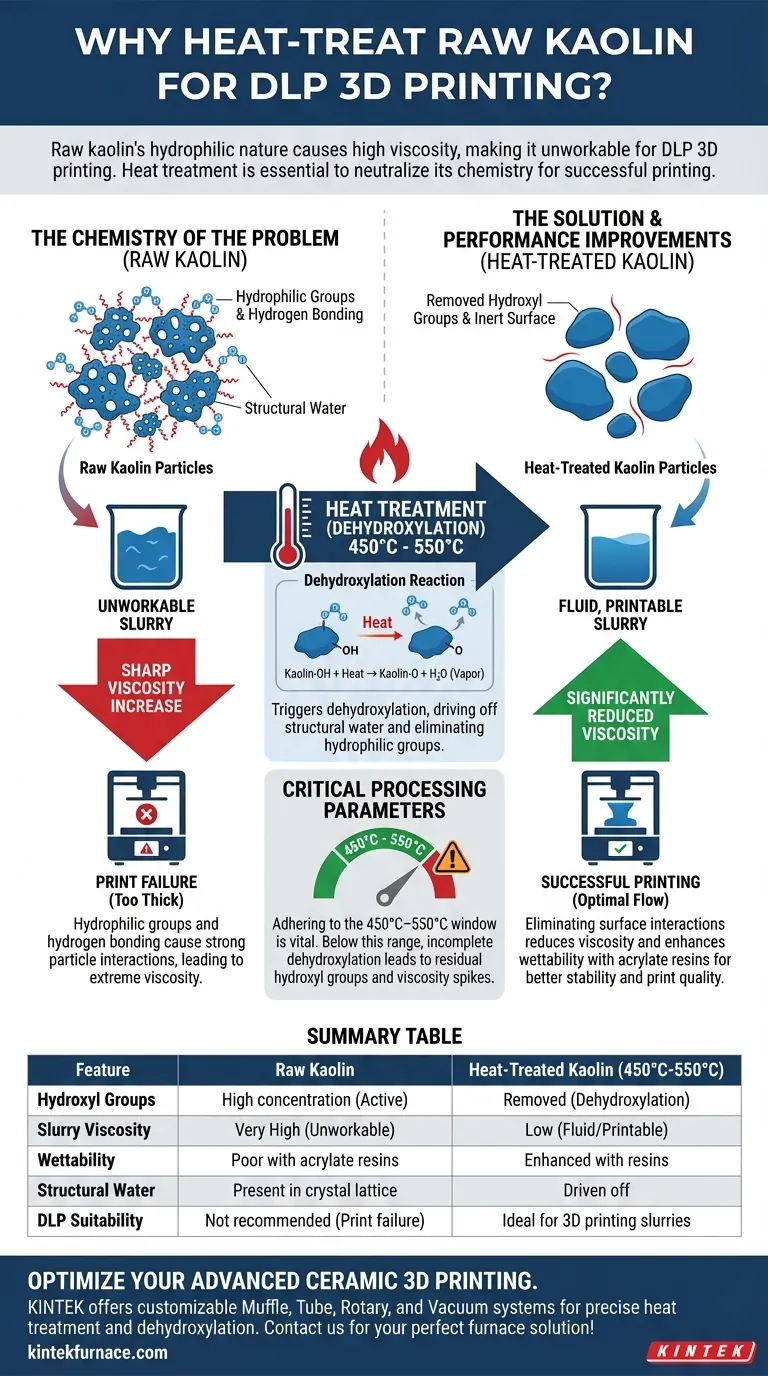

Raw kaolin requires heat treatment prior to use in Digital Light Processing (DLP) to neutralize its surface chemistry, specifically by removing hydrophilic hydroxyl groups. Without this thermal processing step, the interaction between raw kaolin and photosensitive resin causes a drastic increase in viscosity, rendering the slurry too thick for the fluid dynamics required by the printing process.

Raw kaolin contains structural water and hydroxyl groups that bond strongly, creating unworkable slurries. Heat treatment between 450°C and 550°C triggers dehydroxylation, effectively stripping these groups to lower viscosity and enable successful printing.

The Chemistry of the Problem

Hydrophilic Groups and Hydrogen Bonding

In its raw state, kaolin is chemically active in ways that are detrimental to 3D printing resins. The material contains a significant number of hydrophilic groups and hydrogen bonding sites.

These surface features cause the particles to interact strongly with one another and the surrounding medium. This chemical "stickiness" resists the flow necessary for liquid processing.

The Impact on Viscosity

When untreated kaolin is added directly to photosensitive resin, the suspension viscosity increases sharply.

DLP technology relies on a liquid resin that can flow back over the build plate quickly and evenly. The high viscosity caused by raw kaolin fails to meet these fluidity requirements, causing print failures or inability to form layers.

The Mechanism of Heat Treatment

Triggering Dehydroxylation

To solve the viscosity issue, the kaolin must undergo heat treatment at temperatures between 450°C and 550°C.

This specific temperature range triggers a chemical reaction known as dehydroxylation. During this phase, the structural water inherently bound within the kaolin crystal lattice is driven off.

Eliminating Surface Interactions

As the structural water is removed, the heat treatment effectively eliminates the problematic hydroxyl groups from the particle surface.

By removing these groups, you remove the chemical sites responsible for hydrogen bonding. This transforms the clay from a hydrophilic material into one that is more chemically inert regarding viscosity buildup.

Improvements in Material Performance

Reduced Slurry Viscosity

The primary result of dehydroxylation is a significant reduction in the viscosity of the final slurry.

This allows the material to flow freely, ensuring that the printer can accurately recoat the build platform between layers without mechanical resistance or air entrapment.

Enhanced Wettability

Heat treatment does not just lower thickness; it improves the interface between the solid and liquid components.

Processing improves the wettability between the kaolin particles and the acrylate resin. This results in a more homogeneous suspension where the resin can effectively coat each particle, leading to better suspension stability and print quality.

Critical Processing Parameters

Adhering to the Temperature Window

It is essential to strictly observe the 450°C to 550°C processing window mentioned in technical literature.

Processing below this range may result in incomplete dehydroxylation, leaving residual hydroxyl groups that will still spike viscosity. The goal is the complete removal of structural water to ensure consistent rheological behavior.

Optimizing Your Slurry Preparation

To ensure your kaolin-based slurries are viable for DLP printing, apply the following principles to your preparation workflow:

- If your primary focus is flow mechanics: Target the 450°C–550°C range to fully trigger dehydroxylation, which is the only way to prevent the sharp viscosity spikes that stall DLP printers.

- If your primary focus is mixture homogeneity: Use this heat treatment to improve the wettability of the particles, ensuring the acrylate resin bonds properly with the ceramic filler.

By systematically removing hydroxyl groups through heat, you convert raw kaolin from an unworkable mineral into a high-performance additive for precision 3D printing.

Summary Table:

| Feature | Raw Kaolin | Heat-Treated Kaolin (450°C-550°C) |

|---|---|---|

| Hydroxyl Groups | High concentration (Active) | Removed (Dehydroxylation) |

| Slurry Viscosity | Very High (Unworkable) | Low (Fluid/Printable) |

| Wettability | Poor with acrylate resins | Enhanced with resins |

| Structural Water | Present in crystal lattice | Driven off |

| DLP Suitability | Not recommended (Print failure) | Ideal for 3D printing slurries |

Optimize Your Advanced Ceramic 3D Printing

Precise thermal processing is the key to transforming raw materials into high-performance 3D printing slurries. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, and Vacuum systems, as well as other lab high-temp furnaces—all fully customizable to meet your specific dehydroxylation and material synthesis needs.

Don't let high viscosity stall your innovation. Empower your laboratory with the precision heating required for superior material performance. Contact KINTEK today to find your perfect furnace solution!

Visual Guide

References

- Viktor Kurylenko, Tetiana Dontsova. ПЕРСПЕКТИВИ ВИКОРИСТАННЯ ТЕХНОЛОГІЇ 3D ДРУКУ DLP ДЛЯ ВИРОБНИЦТВА МЕМБРАННИХ КЕРАМІЧНИХ МОДУЛІВ. DOI: 10.15421/jchemtech.v33i2.317663

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a Bridgman furnace control single-crystal quality? Master Precision Directional Solidification

- What is the objective of performing an annealing treatment? Enhance Plasticity and Stress Relief for Al-Composites

- Why is a precision furnace required after TiO2-alpha-Ga2O3 synthesis? Master Phase Transformation & Interface Bonding

- What is the significance of the calcination process for LaOx-modified platinum-based catalysts? Unlocking Pure Activity

- What is the primary purpose of utilizing an argon gas purging process during waste pyrolysis? Ensure Pure Decomposition

- What is the function of a solvothermal reactor? Optimize Carbon Polymer Dots (CPDs) Synthesis with Precision Pressure

- What is the function of a magnetron sputtering system for WS2 thin films? Master Nano-Scale Deposition Control

- What are the advantages of Spark Plasma Sintering (SPS) for diffusion bonding? Precision in Atomic Diffusion