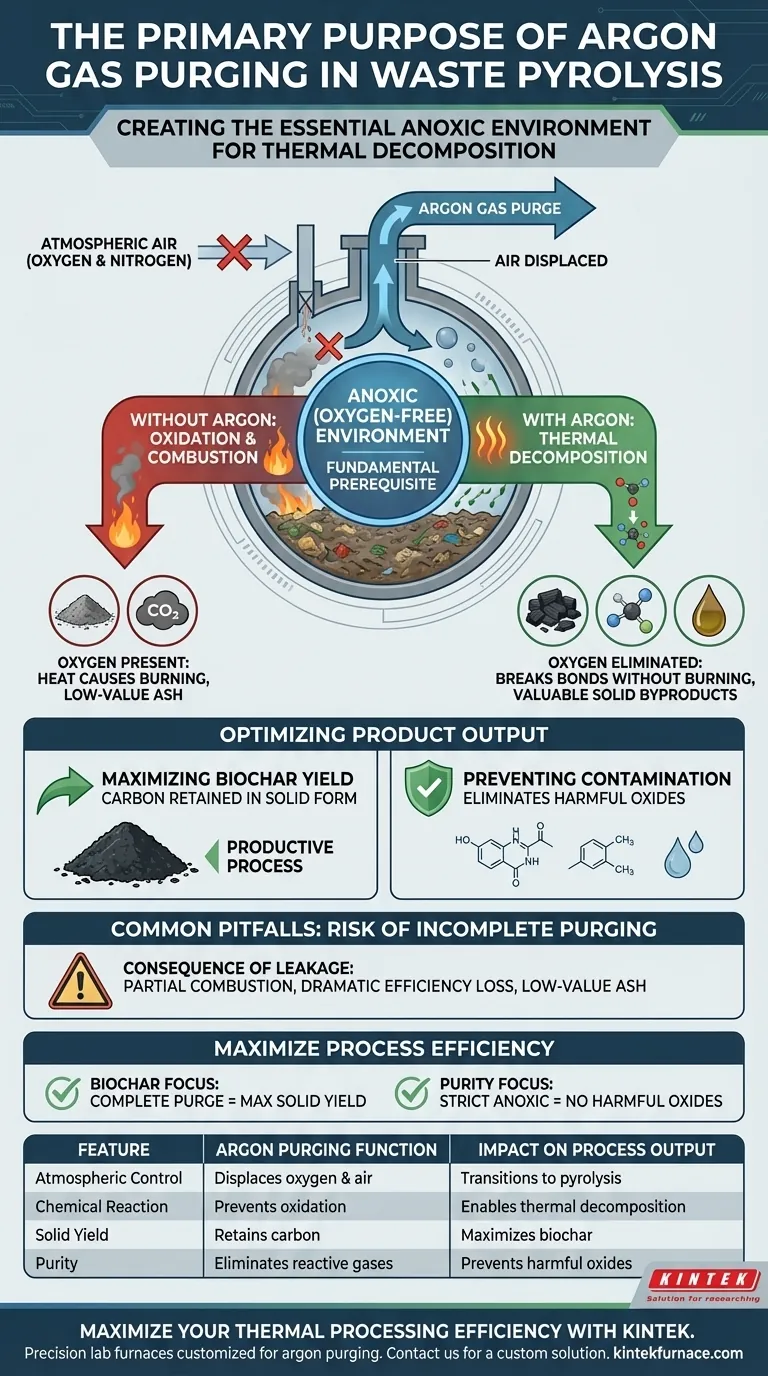

The primary purpose of argon gas purging is to completely displace atmospheric air from the reactor system before the heating process begins. This step creates a strictly anoxic (oxygen-free) environment, which is the fundamental prerequisite for pyrolysis to occur effectively.

By eliminating oxygen, argon purging ensures that organic waste undergoes thermal decomposition rather than combustion. This distinction is critical for preventing the material from simply burning away and is essential for maximizing the production of valuable solid byproducts.

The Critical Role of the Anoxic Environment

To understand why argon purging is non-negotiable, one must look at the fundamental chemistry of the pyrolysis process.

Excluding Atmospheric Air

The reactor system naturally contains air—and therefore oxygen—prior to operation.

Argon is introduced to thoroughly exclude this air. It acts as a displacement agent, flushing the system to ensure no reactive gases remain.

Decomposition vs. Oxidation

The difference between pyrolysis and burning is the presence of oxygen.

In an oxygen-rich environment, heat causes oxidation, turning organic matter into ash and gases. In an anoxic environment created by argon, heat causes thermal decomposition, breaking down chemical bonds without combustion.

Optimizing Product Output

The purging process is directly tied to the quality and quantity of the final output.

Maximizing Biochar Yield

If oxygen is present, carbon within the waste reacts to form Carbon Dioxide (CO2) and escapes as gas.

By maintaining an anoxic state, the carbon is retained in solid form. This significantly maximizes the yield of solid biochar, ensuring the process remains productive rather than destructive.

Preventing Contamination

Air contains various elements that can react unpredictably at high temperatures.

Purging prevents the formation of harmful oxides. By removing the oxygen source, you eliminate the chemical pathway required for these undesirable compounds to form.

Common Pitfalls: The Risk of Incomplete Purging

While the concept is simple, the execution is vital to the system's success.

The Consequence of Leakage

If the system is not thoroughly purged, or if leaks allow air to re-enter, the process enters a hybrid state of partial combustion.

This results in a dramatic loss of efficiency. Instead of converting waste into usable fuel or char, the material consumes itself, leaving behind low-value ash.

Maximizing Your Process Efficiency

To ensure your pyrolysis project succeeds, view argon purging as a foundational control step, not just a safety measure.

- If your primary focus is Biochar Production: You must ensure a complete purge to prevent carbon oxidation, which directly diminishes your solid yield.

- If your primary focus is Chemical Purity: You must maintain a strictly anoxic environment to prevent oxygen from reacting with waste components to form harmful oxides.

Establishing a verifiable oxygen-free atmosphere is the single most important factor in transitioning from waste incineration to true resource recovery.

Summary Table:

| Feature | Argon Purging Function | Impact on Process Output |

|---|---|---|

| Atmospheric Control | Displaces oxygen and air | Transitions process from combustion to pyrolysis |

| Chemical Reaction | Prevents oxidation | Enables thermal decomposition without burning |

| Solid Yield | Retains carbon in solid form | Maximizes high-quality biochar production |

| Purity | Eliminates reactive gases | Prevents formation of harmful oxides and ash |

Maximize Your Thermal Processing Efficiency with KINTEK

Precision is the difference between simple incineration and high-value resource recovery. At KINTEK, we understand that maintaining a strictly anoxic environment is critical for your research and production success.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temperature furnaces are fully customizable to handle complex argon purging requirements, ensuring your waste pyrolysis achieves maximum biochar yield and chemical purity.

Ready to upgrade your lab's capabilities? Contact us today to consult with our specialists about a custom solution for your unique thermal processing needs.

Visual Guide

References

- Zsolt Dobó, Gábor Nagy. Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission. DOI: 10.3390/en18010144

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the primary function of a vacuum oven for Mo-based catalyst precursors? Ensure Purity & Pore Integrity

- Why Use a Vacuum Drying Oven for Ti3C2 MXene@NiS or Co4S3? Prevent Oxidation and Preserve Catalyst Integrity

- What is the objective of setting temperature gradients of 40 °C, 50 °C, and 60 °C? Optimize Yogurt Drying Viability

- What role does Iodine (I2) play as a transport agent in CVT for FexTaSe2? Unlock Efficient Single Crystal Growth

- What is the function of a Mass Flow Controller (MFC)? Achieve Precise Ethanol Vapor Delivery for Graphene Synthesis

- What are the functions of hot isostatic pressing (HIP) equipment? Achieve Peak Density in Powder Metallurgy

- What is the purpose of vacuum sputtering systems for haptic device electrodes? Achieve High-Precision Metal Deposition

- Why is a constant temperature incubator required for 10-week fungal testing of Moso Bamboo? Ensure Testing Accuracy