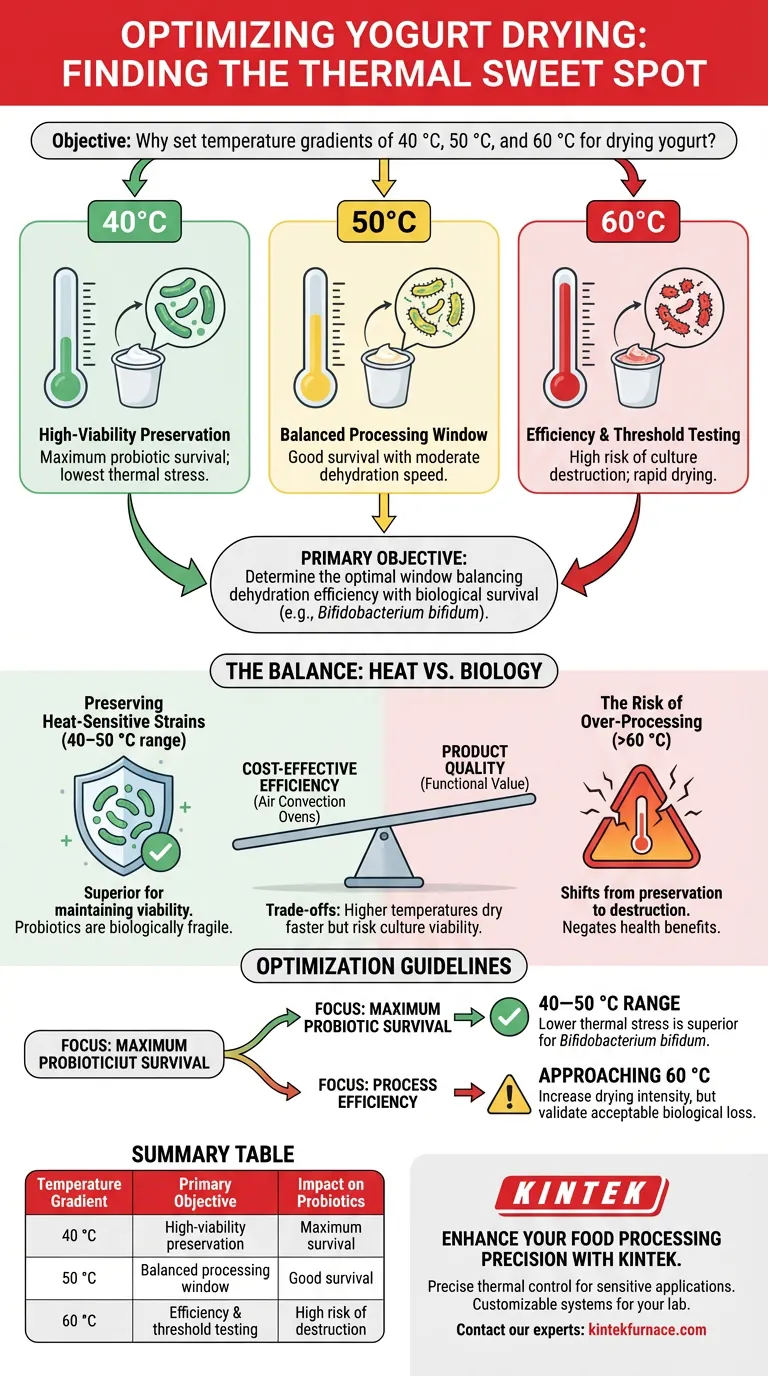

The primary objective of setting temperature gradients at 40 °C, 50 °C, and 60 °C is to determine the optimal processing window that balances dehydration efficiency with biological survival.

By isolating these specific thermal points, operators can identify the exact temperature threshold where moisture is removed effectively without destroying heat-sensitive probiotics, specifically strains like Bifidobacterium bifidum.

While air convection drying is a cost-effective method for dehydration, it relies on continuous heat that can easily compromise product quality. Testing across this 40–60 °C range is critical to finding the "sweet spot" where the product dries sufficiently while maintaining high probiotic viability.

The Balance Between Heat and Biology

Isolating the Variable of Thermal Intensity

The purpose of using a gradient (steps of 10 °C) is to perform a comparative analysis.

Rather than relying on a single setting, testing at 40 °C, 50 °C, and 60 °C creates a data set that reveals how drastically probiotic survival drops as thermal intensity increases.

Preserving Heat-Sensitive Strains

The central challenge in drying yogurt is that the active cultures are biologically fragile.

Experiments confirm that maintaining lower temperatures, specifically within the 40–50 °C range, is superior for preserving viability. As the temperature pushes toward 60 °C, the survival rate of sensitive strains like Bifidobacterium bifidum is likely to diminish significantly.

Understanding the Trade-offs

Cost-Effectiveness vs. Product Quality

Air convection ovens are utilized because they are a cost-effective dehydration technology.

However, this economic advantage is lost if the final product lacks functional value. The trade-off is that while higher temperatures might dry the product faster, they risk negating the health benefits associated with the yogurt cultures.

The Risk of Over-Processing

Setting the temperature too high (e.g., approaching or exceeding 60 °C) shifts the outcome from preservation to destruction.

The objective of the lower gradients (40 °C and 50 °C) is to prove that successful dehydration is possible without reaching temperatures that sterilize the product.

Optimization for Your Process

Based on the comparative results of these gradients, here is how you should prioritize your parameters:

- If your primary focus is Maximum Probiotic Survival: Prioritize the 40–50 °C range, as this lower thermal stress is proven superior for maintaining viable Bifidobacterium bifidum populations.

- If your primary focus is Process Efficiency: Recognize that while temperatures approaching 60 °C may increase drying intensity, you must validate that the resulting loss in biological activity is acceptable for your specific product goals.

The data indicates that a controlled, lower-temperature approach is the definitive path for high-quality probiotic retention.

Summary Table:

| Temperature Gradient | Primary Objective | Impact on Probiotics (e.g., Bifidobacterium) |

|---|---|---|

| 40 °C | High-viability preservation | Maximum survival; lowest thermal stress |

| 50 °C | Balanced processing window | Good survival with moderate dehydration speed |

| 60 °C | Efficiency & threshold testing | High risk of culture destruction; rapid drying |

Enhance Your Food Processing Precision with KINTEK

Maintaining the delicate balance between dehydration efficiency and biological viability requires precise thermal control. Backed by expert R&D and manufacturing, KINTEK offers high-performance laboratory convection ovens and specialized systems tailored for sensitive food science applications.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our equipment is fully customizable to meet your unique research and production needs. Don't compromise your product's functional value—contact our technical experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- Fatimah Eesee Jaafar, Alaa Kareem Niamah. Effect of Different Air Oven Temperatures on Chemical, Physical, and Microbial Properties of Dried Bio-Yoghurt Product. DOI: 10.3390/dairy5010004

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the heat treatment of NC6 (1.2063) tool steel affect its performance? Key SPIF Tool Optimization

- How is mechanochemical grinding used in lithium battery recovery? Unlock Efficient Solid-State Material Repair

- What is the purpose of a safety warning system in MDR? Ensure Reactor Integrity and Laboratory Safety

- What is the purpose of pre-baking sapphire substrates? Master Atomic Flatness for Superior Thin Film Growth

- Why is the use of silver-containing active brazing alloys prohibited in TEGs? Prevent Semiconductor Degradation

- Why is a high-precision programmed heating furnace essential for the annealing reduction of intermetallic compounds?

- What are the advantages of Spark Plasma Sintering (SPS) for TiC alloys? Preserve Precision and Microstructure

- What is the role of a high-temperature stainless steel autoclave in the synthesis of Copper Ferrite (CuFe2O4)?