The fundamental purpose of pre-baking sapphire substrates in a high-temperature muffle furnace is to achieve rigorous thermal cleaning prior to deposition. By exposing the single-crystal sapphire (Al2O3) to temperatures around 1000°C, you effectively remove adsorbed impurities and organic contaminants that standard chemical cleaning might miss.

Pre-baking is not merely about hygiene; it is about structural preparation. This process prepares the sapphire as an atomically flat physical template, which is the absolute prerequisite for successful, high-quality epitaxial thin film growth.

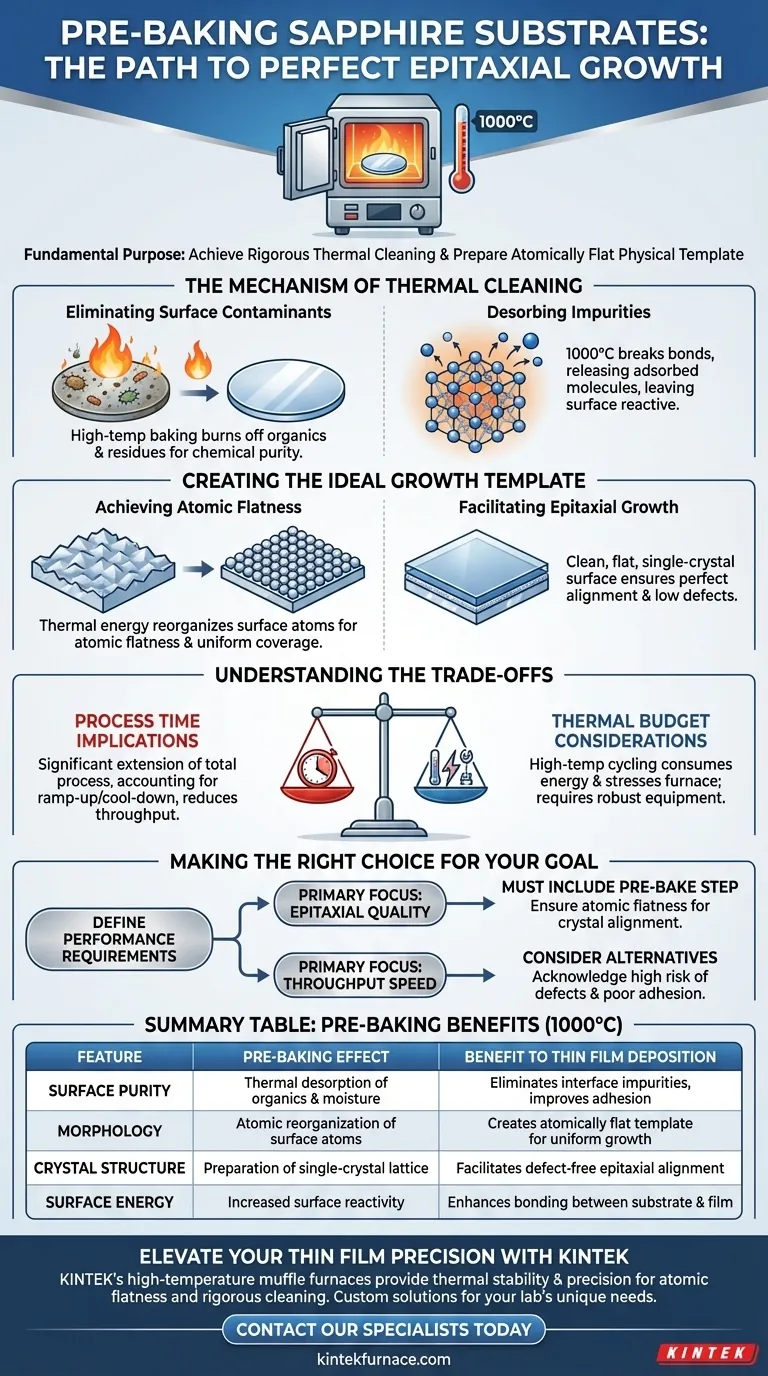

The Mechanism of Thermal Cleaning

Eliminating Surface Contaminants

Sapphire substrates often retain microscopic organic residues or moisture from storage and handling.

High-temperature baking burns off these organic contaminants. It ensures the surface is chemically pure before it enters the deposition chamber.

Desorbing Impurities

Surfaces tend to "adsorb" or hold onto foreign molecules from the atmosphere.

The energy provided by the 1000°C environment breaks the bonds holding these impurities to the sapphire. This leaves the substrate surface "naked" and reactive, ready for the next layer.

Creating the Ideal Growth Template

Achieving Atomic Flatness

For high-performance applications, a clean surface is not enough; it must also be morphologically perfect.

The thermal energy from the baking process helps reorganize the surface atoms. This results in an atomically flat surface, reducing roughness that could impede uniform film coverage.

Facilitating Epitaxial Growth

Epitaxy requires the deposited film to align perfectly with the crystal structure of the substrate.

By creating a clean, flat, single-crystal surface, the sapphire acts as an ideal physical template. This allows the subsequent thin film to grow with high structural integrity and fewer defects.

Understanding the Trade-offs

Process Time Implications

Adding a pre-bake step, specifically for one hour at 1000°C, significantly extends the total process time.

You must account for the ramp-up and cool-down times of the muffle furnace to ensure safety. This can reduce overall manufacturing throughput.

Thermal Budget Considerations

While sapphire is robust, high-temperature cycling consumes energy and stresses the furnace equipment.

You must ensure that your specific muffle furnace is rated for sustained operation at these temperatures to avoid equipment degradation.

Making the Right Choice for Your Goal

When deciding whether to integrate this high-temperature pre-bake into your workflow, consider your specific performance requirements.

- If your primary focus is epitaxial quality: You must include the pre-bake step to ensure the atomic flatness required for crystal alignment.

- If your primary focus is throughput speed: You might consider alternative cleaning methods, but acknowledge the high risk of interface defects and poor adhesion.

A pristine, atomically ordered substrate is the single most critical factor in defining the ultimate performance of your thin film device.

Summary Table:

| Feature | Pre-Baking Effect (1000°C) | Benefit to Thin Film Deposition |

|---|---|---|

| Surface Purity | Thermal desorption of organics & moisture | Eliminates interface impurities and improves adhesion |

| Morphology | Atomic reorganization of surface atoms | Creates an atomically flat template for uniform growth |

| Crystal Structure | Preparation of single-crystal lattice | Facilitates defect-free epitaxial alignment |

| Surface Energy | Increased surface reactivity | Enhances bonding between substrate and deposited film |

Elevate Your Thin Film Precision with KINTEK

High-quality epitaxial growth starts with a pristine substrate. KINTEK’s high-temperature muffle furnaces provide the thermal stability and precision required to achieve atomic flatness and rigorous thermal cleaning for sapphire substrates.

Backed by expert R&D and world-class manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your laboratory’s unique high-temperature processing needs. Don't compromise on your structural integrity; trust KINTEK to provide the reliable equipment your research demands.

Contact our specialists today to find your custom furnace solution

Visual Guide

References

- Ke Tang, Seiji Mitani. Enhanced orbital torque efficiency in nonequilibrium Ru50Mo50(0001) alloy epitaxial thin films. DOI: 10.1063/5.0195775

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a box heater work? A Guide to Efficient Whole-Room Heating

- What is the function of a planetary high-energy ball mill in Al2O3/TiC ceramics? Achieve Sub-Micron Precision Today

- What hardware characteristics are required for a reactor system to support a three-step redox process in chemical looping?

- What role does Sodium Chloride (NaCl) play as a thermal buffer? Optimizing Si/Mg2SiO4 Composite Synthesis

- What is graphite furnace atomic absorption spectroscopy used for? Detecting Trace Elements at Parts-Per-Billion Levels

- What is the importance of dental restorations? Restore Function and Prevent Oral Health Decline

- What are the advantages of using an optical floating zone furnace for VNbMoTaW? Achieve Ultra-High Purity Homogenization

- Why is a constant-temperature blast drying oven necessary for processing biomass precursors? Ensure Structural Integrity