The primary advantage of using an optical floating zone furnace with xenon lamp heating is its capability to achieve ultra-high annealing temperatures while maintaining absolute material purity. Unlike conventional laboratory furnaces, which cannot reach the ~2000°C required for VNbMoTaW alloys, this method uses focused light to induce element diffusion and stabilize the alloy's single-phase body-centered cubic (BCC) structure without using a crucible.

The extreme melting point of VNbMoTaW (approx. 2682 K) renders standard muffle furnaces ineffective for homogenization. Xenon lamp heating solves this by providing a focused, high-intensity energy source that processes the material locally, eliminating container contamination and ensuring the formation of a stable crystal structure.

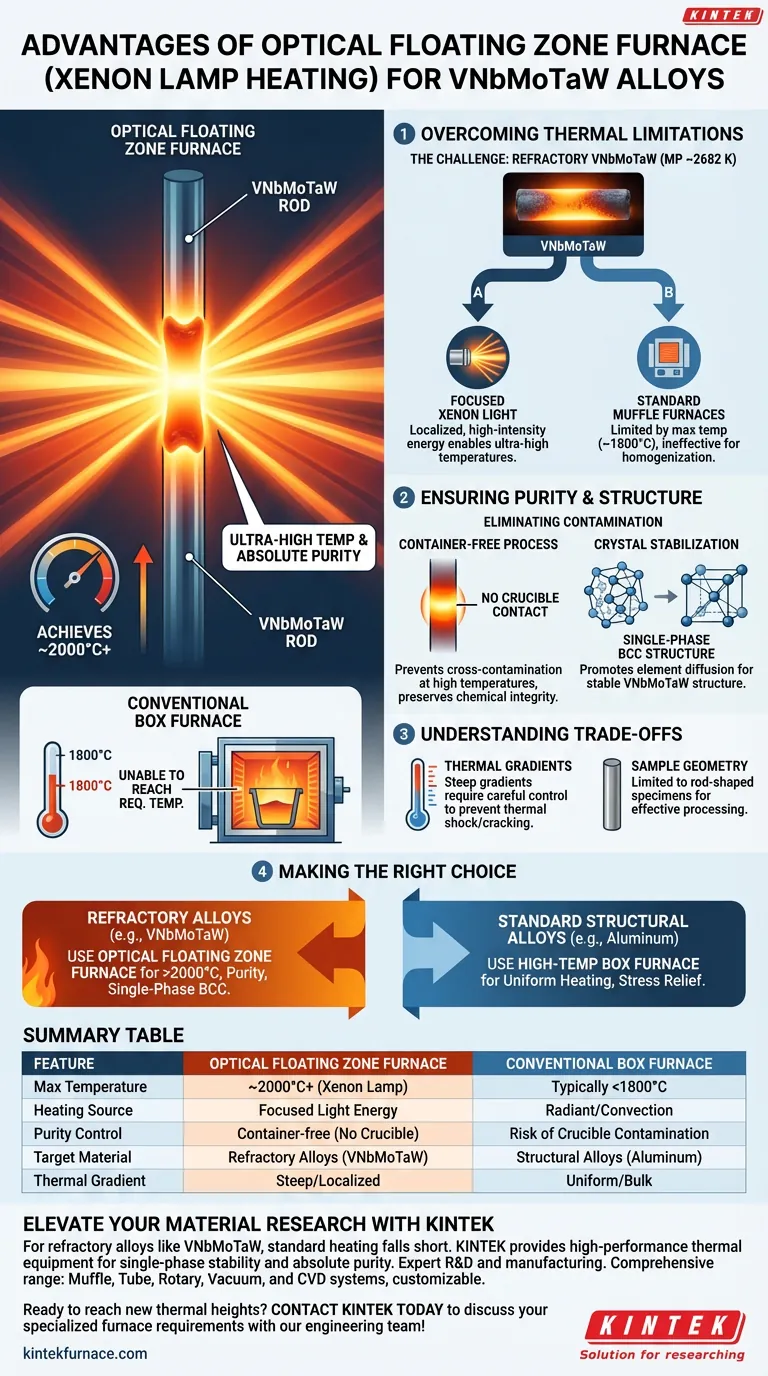

Overcoming Thermal Limitations

The Challenge of Refractory Alloys

VNbMoTaW is a refractory alloy with an exceptionally high melting point of approximately 2682 K. Conventional heat treatment equipment, such as the box furnaces used for aluminum alloys (e.g., AA6061 at 415°C), simply cannot reach the temperatures necessary to affect this material.

Reaching Homogenization Temperatures

To properly anneal VNbMoTaW, temperatures often need to approach 2000°C. Standard laboratory muffle furnaces are generally incapable of sustaining these thermal levels.

The Power of Focused Xenon Light

An optical floating zone furnace utilizes high-power xenon lamps to circumvent standard heating limits. By concentrating light energy onto a specific zone of the specimen, it generates the intense, localized heat required to process ultra-high melting point materials.

Ensuring Purity and Structure

Eliminating Container Contamination

A critical advantage of the floating zone method is that it is a "container-free" process. Because the material is heated locally while suspended or supported by its own solid sections, there is no contact with a crucible or vessel.

Prevention of Impurities

At temperatures near 2000°C, most alloys become highly reactive and would chemically attack or absorb impurities from a standard crucible. Xenon lamp heating prevents this cross-contamination, preserving the chemical integrity of the VNbMoTaW alloy.

Stabilizing the Crystal Structure

The ultimate goal of this high-temperature annealing is homogenization. The focused heat effectively promotes the diffusion of elements within the alloy, resulting in a stable, single-phase body-centered cubic (BCC) structure.

Understanding the Trade-offs

Managing Thermal Gradients

While localized heating is powerful, it creates steep temperature gradients compared to the uniform environment of a box furnace. For brittle alloys like VNbMoTaW, this requires careful control to prevent thermal shock or cracking during cooling.

Sample Geometry Constraints

Unlike box furnaces that can accept various shapes, floating zone furnaces typically require rod-shaped specimens. This limits the geometry of the material you can process effectively.

Making the Right Choice for Your Goal

To select the correct heating method, evaluate the physical properties of your specific alloy system.

- If your primary focus is refractory alloys (e.g., VNbMoTaW): You must use an optical floating zone furnace to reach ~2000°C and achieve a pure, single-phase BCC structure without crucible contamination.

- If your primary focus is standard structural alloys (e.g., Aluminum AA6061): You should utilize a high-temperature box furnace to ensure uniform bulk heating and precise stress relief at lower temperatures.

Choose the method that aligns with the melting point and reactivity of your material to ensure structural integrity.

Summary Table:

| Feature | Optical Floating Zone Furnace | Conventional Box Furnace |

|---|---|---|

| Max Temperature | ~2000°C+ (Xenon Lamp) | Typically <1800°C |

| Heating Source | Focused Light Energy | Radiant/Convection |

| Purity Control | Container-free (No Crucible) | Risk of Crucible Contamination |

| Target Material | Refractory Alloys (VNbMoTaW) | Structural Alloys (Aluminum) |

| Thermal Gradient | Steep/Localized | Uniform/Bulk |

Elevate Your Material Research with KINTEK

For refractory alloys like VNbMoTaW, standard heating solutions fall short. KINTEK provides the high-performance thermal equipment necessary to achieve single-phase stability and absolute purity. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of laboratory solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique metallurgical needs.

Ready to reach new thermal heights? Contact KINTEK today to discuss your specialized furnace requirements with our engineering team!

Visual Guide

References

- Tomohito Tsuru, Haruyuki Inui. Intrinsic factors responsible for brittle versus ductile nature of refractory high-entropy alloys. DOI: 10.1038/s41467-024-45639-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How are heat treatment furnaces utilized in the automotive industry? Enhance Component Durability and Performance

- What are the advantages of HTL reactors for algae? Optimize Biomass Conversion Without Pre-Drying

- What physical environment does a laboratory oven provide for perovskite annealing? Master Thermal Precision & Strain Control

- Why is temperature gradient management necessary for high-temperature impedance measurements? Master Thermal Precision

- Why is precise control of heating and cooling rates necessary for iron-doped ceria? Optimize Your Catalyst Performance

- Why is it necessary to dry glassware in a 140 °C oven overnight before GTP? Ensure Precise Anhydrous Polymerization

- What is the importance of dynamic sealing in an InP crystal growth furnace? Ensure Pressure Integrity & Motion Control

- What is the purpose of using a precision oven for HAp-Fe3O4 drying? Achieve 110°C Stability & High Porosity