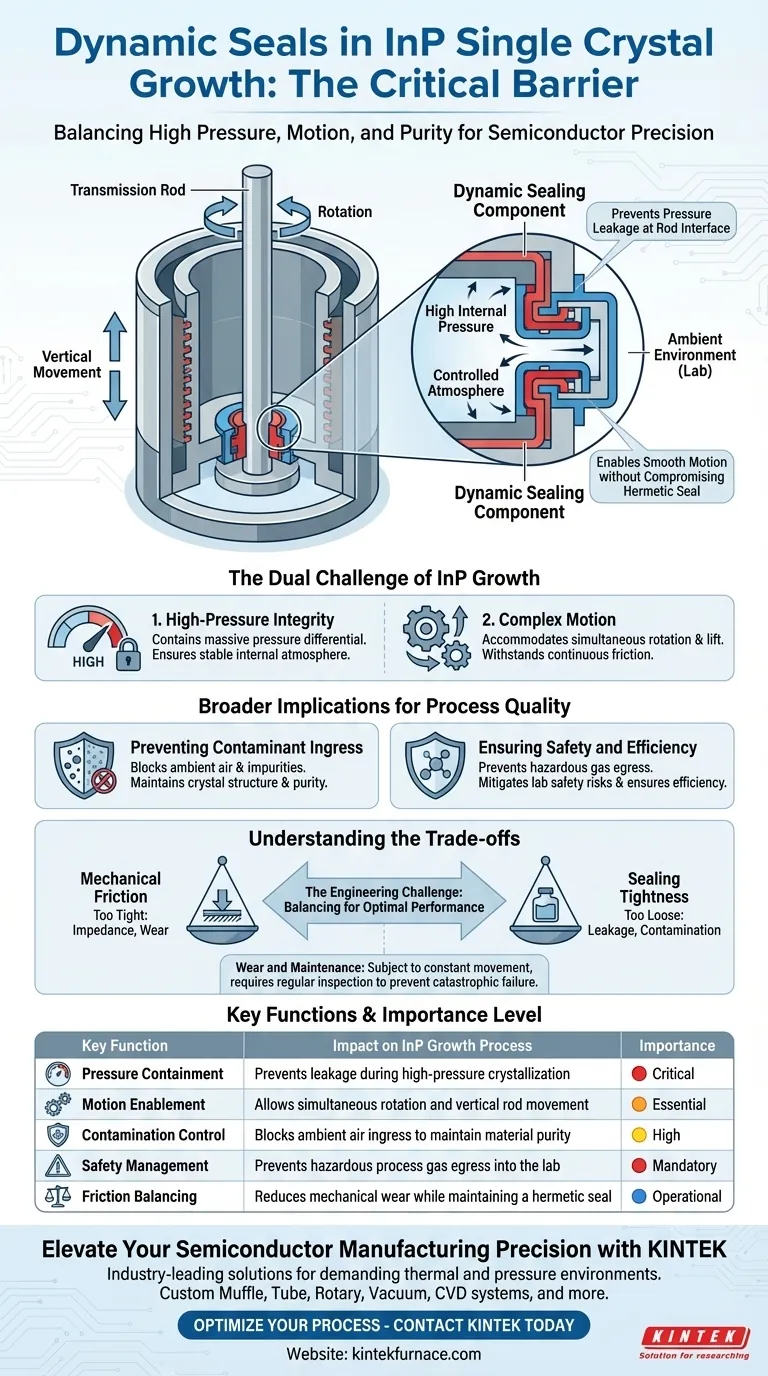

Dynamic sealing components serve as the critical barrier that maintains the integrity of the high-pressure environment within an Indium Phosphide (InP) single crystal growth furnace. Specifically, they prevent pressure leakage at the precise point where the transmission rod passes through the furnace base, allowing the shaft to rotate and move vertically without compromising the internal processing chamber.

The growth of Indium Phosphide requires both high internal pressure and complex mechanical movement. Dynamic seals bridge these conflicting requirements, preventing pressure loss and contamination while permitting the transmission system to execute precise motion control.

The Dual Challenge of InP Growth

Maintaining High-Pressure Integrity

Indium Phosphide crystal growth is unique because it necessitates a high-pressure environment.

The dynamic seal is located at the interface where the transmission rod enters the furnace base. Its primary function is to contain this pressure, ensuring that the internal atmosphere remains stable despite the massive pressure differential compared to the outside environment.

Enabling Complex Motion

Unlike static components, the transmission system is not stationary.

The shaft must undergo both rotation and vertical movement to control the crystal growth process. Dynamic seals are engineered to accommodate this continuous friction and motion without breaking the hermetic seal, allowing the mechanism to execute precise control commands.

Broader Implications for Process Quality

Preventing Contaminant Ingress

Beyond pressure containment, effective sealing is vital for chemical purity.

If a seal fails, ambient air can leak into the chamber. This ingress introduces contaminants that disrupt the strictly controlled atmosphere, potentially ruining the single crystal structure and wasting valuable raw materials.

Ensuring Safety and Efficiency

The containment of controlled gases is equally important for operational safety.

Dynamic seals prevent the egress (leakage) of process gases into the laboratory environment. Preventing these leaks mitigates safety hazards for operators and ensures the process remains thermally and chemically efficient.

Understanding the Trade-offs

Mechanical Friction vs. Sealing Tightness

The central engineering challenge with dynamic seals is balancing friction against isolation.

A seal that is too tight provides excellent pressure containment but introduces excessive friction, which can impede the smooth rotation and lift of the transmission rod. Conversely, a looser seal reduces mechanical wear but increases the risk of pressure leakage and contamination.

Wear and Maintenance Cycles

Because these components are subjected to constant movement under high pressure, they are consumable points of failure.

Dynamic seals experience significantly more wear than static gaskets or door seals. Neglecting regular inspection of these specific components can lead to catastrophic pressure loss during a growth cycle, making them a critical maintenance priority.

Making the Right Choice for Your Goal

To ensure the reliability of your InP growth furnace, consider your primary operational objectives when evaluating sealing systems:

- If your primary focus is Crystal Purity: Prioritize seal materials and designs that offer the highest rating against gas ingress to eliminate ambient contamination risks.

- If your primary focus is Motion Precision: Select dynamic seals with low-friction coefficients to ensure the transmission rod moves smoothly without "stick-slip" behavior.

Ultimately, the dynamic seal is the linchpin that allows mechanical precision to coexist with the extreme environmental conditions required for semiconductor manufacturing.

Summary Table:

| Key Function | Impact on InP Growth Process | Importance Level |

|---|---|---|

| Pressure Containment | Prevents leakage during high-pressure crystallization | Critical |

| Motion Enablement | Allows simultaneous rotation and vertical rod movement | Essential |

| Contamination Control | Blocks ambient air ingress to maintain material purity | High |

| Safety Management | Prevents hazardous process gas egress into the lab | Mandatory |

| Friction Balancing | Reduces mechanical wear while maintaining a hermetic seal | Operational |

Elevate Your Semiconductor Manufacturing Precision with KINTEK

Maintaining the delicate balance between high-pressure containment and mechanical fluid motion is vital for Indium Phosphide crystal growth. KINTEK provides industry-leading solutions designed to handle the most demanding thermal and pressure environments.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all of which are fully customizable to meet your unique sealing and motion control requirements. Whether you are scaling production or conducting advanced material research, our engineering team ensures your equipment delivers consistent, high-purity results.

Ready to optimize your high-temperature processes? Contact us today to discuss your custom furnace needs and see how our expertise can enhance your laboratory's efficiency.

Visual Guide

References

- Hua Wei, Hui Feng. Growth of 4-Inch InP Single-Crystal Wafer Using the VGF-VB Technique. DOI: 10.1021/acsomega.4c09376

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- Why is a specialized roasting simulation device necessary? Optimize Iron Ore Pellet Quality and Strength

- Why is 500°C thermal stabilization necessary for titania supports? Ensure Catalyst Stability and Performance

- What is the function of a drying oven for oil shale semi-coke? Achieve Precise Sample Standardization

- Why are specific temperatures of 848 K, 898 K, and 948 K selected for the Thermal Oxidation of Ti-6Al-4V ELI alloy?

- Why is a forced air drying oven essential after molding biomass briquettes? Enhance Fuel Quality & Strength

- What factors are assessed during the evaluation for an Industrial Furnace project? Optimize Your Thermal Process

- Why is precise superheat temperature control required? Unlock High-Quality Soft Magnetic Nanocrystalline Alloys