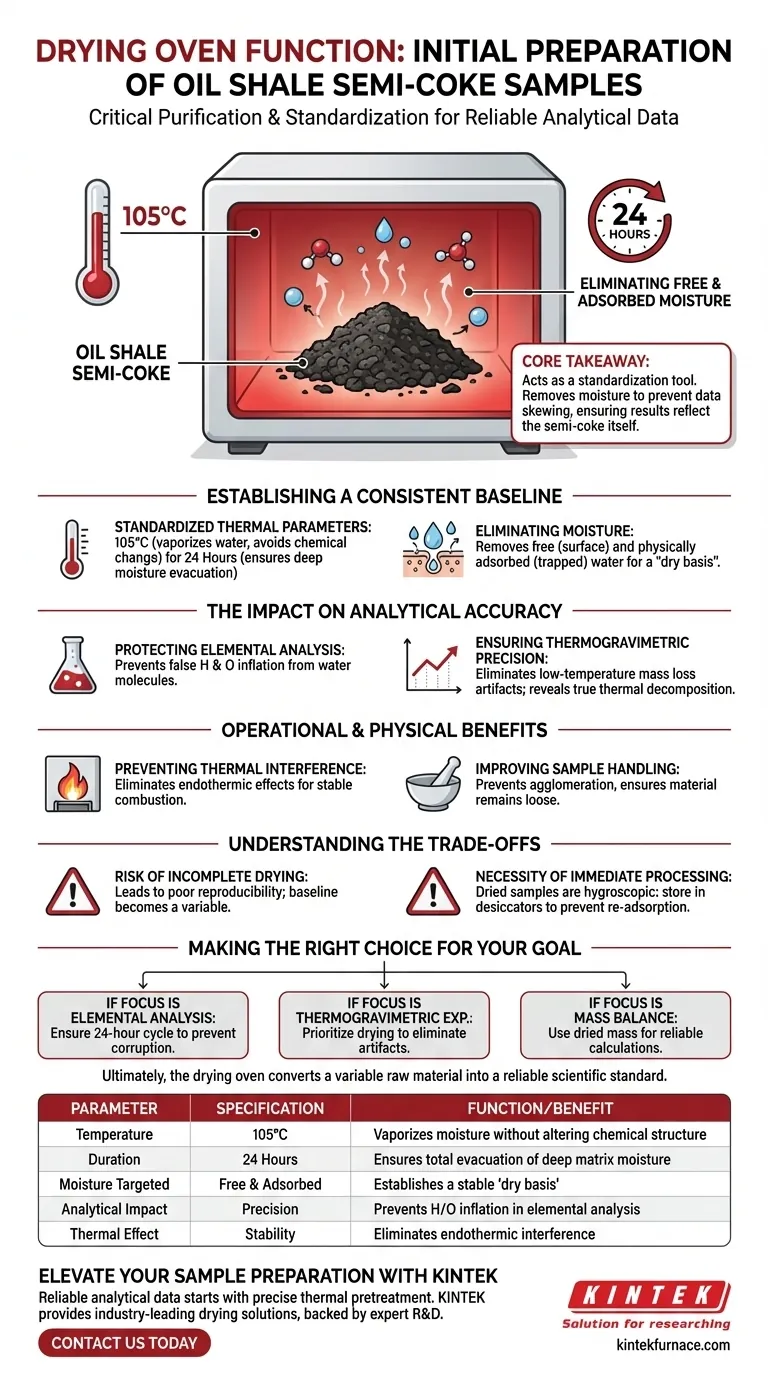

In the initial preparation of oil shale semi-coke samples, the drying oven serves a critical purification function by treating raw materials at 105°C for 24 hours. This precise thermal cycle is designed to thoroughly eliminate physically adsorbed water and free moisture, ensuring the material is chemically and physically stable before further processing.

Core Takeaway The drying oven acts as a standardization tool. By removing moisture, it prevents water mass from skewing analytical data, ensuring that subsequent results—specifically elemental analysis and thermogravimetric experiments—reflect the properties of the semi-coke itself, rather than environmental humidity.

Establishing a Consistent Baseline

Standardized Thermal Parameters

To achieve reproducible results, the drying process must follow a strict protocol.

The primary reference dictates treating the oil shale materials at 105°C. This temperature is high enough to vaporize water efficiently but low enough to avoid altering the chemical structure of the semi-coke.

The duration of this treatment is 24 hours. This extended period ensures that moisture deep within the sample matrix is fully evacuated, leaving only the solid fuel components.

Eliminating Free and Adsorbed Moisture

Raw oil shale and semi-coke naturally retain moisture from the environment.

The oven removes free moisture (surface water) and physically adsorbed water (water trapped in pores). Removing both is necessary to establish a "dry basis" for all subsequent mass calculations.

The Impact on Analytical Accuracy

Protecting Elemental Analysis

Accurate elemental analysis relies on precise mass measurements.

If moisture remains in the sample, the hydrogen and oxygen present in the water molecules will be detected during analysis. This falsely inflates the hydrogen and oxygen content of the semi-coke, distorting the chemical profile of the fuel.

Ensuring Thermogravimetric Precision

Thermogravimetric experiments measure mass loss over time as temperature increases.

If the sample is not pre-dried, the evaporation of residual water during the experiment will register as mass loss. This obscures the true thermal decomposition behavior of the semi-coke, making it difficult to distinguish between moisture evaporation and actual volatile matter release.

Operational and Physical Benefits

Preventing Thermal Interference

Moisture evaporation is an endothermic process, meaning it absorbs heat.

As noted in supplementary contexts regarding fuel samples, releasing moisture inside a high-temperature furnace can cause local temperature drops. Pre-drying prevents these endothermic effects, ensuring the combustion temperature remains stable and experimental data remains reproducible.

Improving Sample Handling

Drying affects the physical state of the material.

While the primary goal is chemical baseline stability, removing moisture also ensures the sample remains loose and flowable. This prevents agglomeration (clumping) during grinding or classification, ensuring the sample is physically consistent.

Understanding the Trade-offs

The Risk of Incomplete Drying

Reducing the drying time below 24 hours or the temperature below 105°C creates significant data risk.

If moisture is only partially removed, the "baseline" becomes a variable rather than a constant. This leads to poor reproducibility, where two identical samples yield different analytical results simply due to varying moisture content.

The Necessity of Immediate Processing

Once dried, oil shale semi-coke is hygroscopic—it will re-adsorb moisture from the air.

The function of the drying oven is negated if samples are not stored in desiccators or processed immediately after removal. The "dry state" is temporary and must be protected to maintain data integrity.

Making the Right Choice for Your Goal

If your primary focus is Elemental Analysis:

- Ensure the 24-hour cycle is completed fully to prevent environmental water hydrogen/oxygen from corrupting your chemical composition data.

If your primary focus is Thermogravimetric Experiments:

- Prioritize this drying step to eliminate low-temperature mass loss artifacts, ensuring that any weight change observed is due strictly to semi-coke decomposition.

If your primary focus is Mass Balance Calculation:

- Use the dried mass as your absolute denominator to calculate reliable residual rates and heavy metal concentrations.

Ultimately, the drying oven converts a variable raw material into a reliable scientific standard.

Summary Table:

| Parameter | Specification | Function/Benefit |

|---|---|---|

| Temperature | 105°C | Vaporizes moisture without altering chemical structure |

| Duration | 24 Hours | Ensures total evacuation of deep matrix moisture |

| Moisture Targeted | Free & Adsorbed | Establishes a stable "dry basis" for mass calculations |

| Analytical Impact | Precision | Prevents hydrogen/oxygen inflation in elemental analysis |

| Thermal Effect | Stability | Eliminates endothermic interference during decomposition |

Elevate Your Sample Preparation with KINTEK

Reliable analytical data starts with precise thermal pretreatment. KINTEK provides industry-leading drying solutions designed to meet the rigorous standards of fuel research and material science. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temp furnaces—all fully customizable to your unique laboratory needs.

Ensure your oil shale and semi-coke samples are standardized for success. Contact us today to find the perfect thermal solution for your lab!

Visual Guide

References

- Fajun Zhao, J. Yun. Study on the Combustion Behavior and Kinetic Characteristics of Semi-Coke from Oil Shale. DOI: 10.3390/app15115797

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the significance of maintaining an inert nitrogen atmosphere during molten salt activation? Ensure Pore Purity

- Why is rapid quenching required during the preparation of amorphous glass fertilizers? Boost Nutrient Solubility

- What are the advantages of using a microwave activation system? Unlock Superior Porosity and 90% Faster Activation

- What is the purpose of performing a 600 degree Celsius annealing treatment? Enhance AZO Thin Film Stability

- How does the single-stage artificial aging process (T6 state) strengthen AA7050 aluminum alloy wire?

- Why is a laboratory vacuum drying oven required for perovskite nanopowders? Safeguard Nanostructure and Purity

- What types of labs benefit most from benchtop industrial ovens? Maximize Space and Efficiency in Your Lab

- How does a gas path control system protect the materials? Ensure High Yields in Battery Smelting