Benchtop industrial ovens are the definitive solution for laboratories defined by two key constraints: limited physical space and low-volume sample processing. These units are specifically engineered for operations where a large, floor-standing oven would be inefficient and impractical, providing precise thermal processing without consuming valuable floor space.

The decision to choose a benchtop oven is not merely about its size. It is a strategic choice to align your equipment's footprint and energy consumption directly with the scale of your lab's daily workflow, ensuring maximum efficiency for small-batch applications.

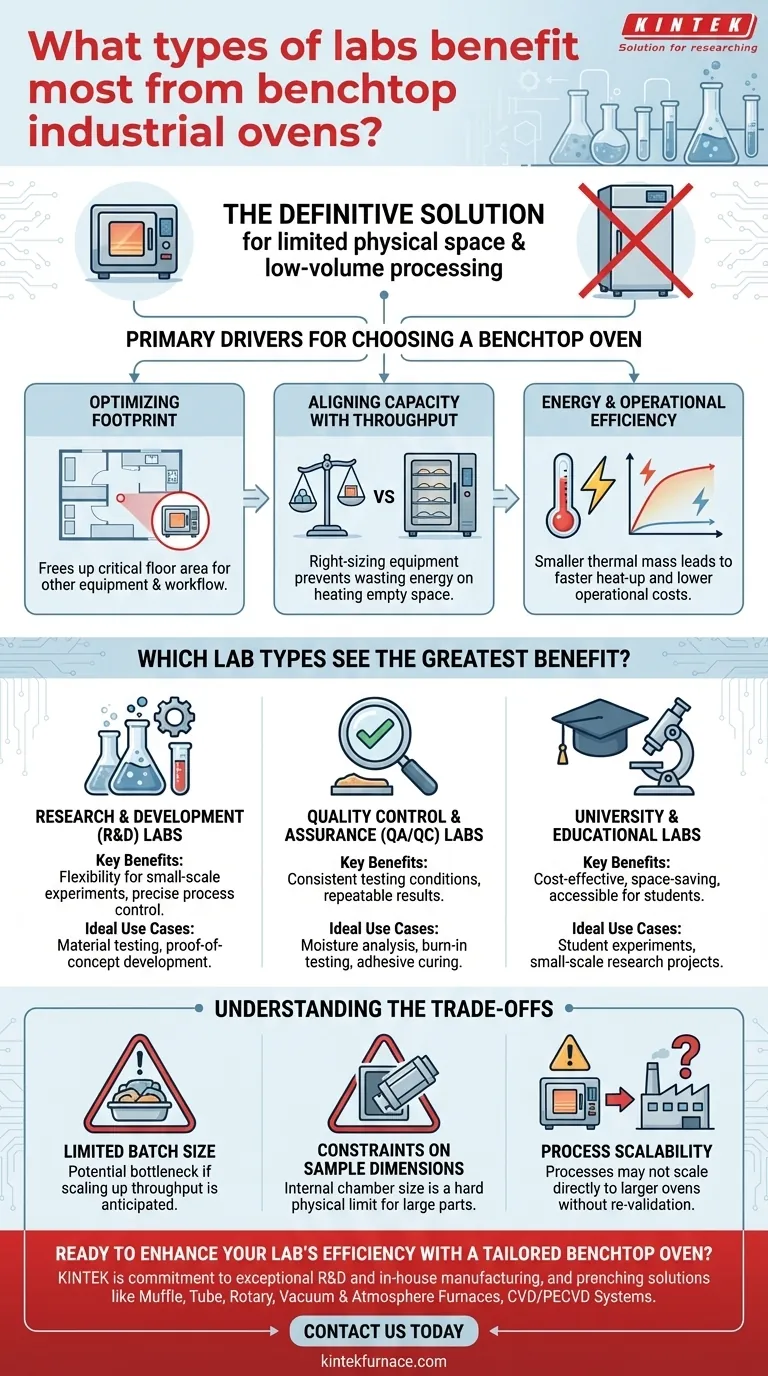

The Primary Drivers for Choosing a Benchtop Oven

Understanding the core advantages of a benchtop model allows you to assess if it aligns with your operational needs. The benefits extend beyond simply saving space.

Optimizing Laboratory Footprint

In any lab, physical space is a finite and valuable resource. A benchtop oven frees up critical floor area for other essential equipment, safer transit paths, or future expansion.

This is especially crucial in labs where every square foot is meticulously planned to optimize workflow and analytical capacity.

Aligning Capacity with Throughput

"Right-sizing" your equipment is a fundamental principle of operational efficiency. Using a large industrial oven to heat a handful of small samples is highly inefficient.

A benchtop oven's smaller chamber is perfectly matched to low-volume or single-piece workflows, ensuring you are not wasting energy or time heating empty space.

Energy and Operational Efficiency

The smaller thermal mass of a benchtop oven means it heats up faster and consumes significantly less energy to maintain its target temperature.

For labs that run frequent but small cycles, these energy savings accumulate, leading to lower operational costs over the lifetime of the equipment.

Which Lab Types See the Greatest Benefit?

While any space-constrained lab can benefit, certain types find benchtop ovens to be an indispensable tool for their specific workflows.

Research & Development (R&D) Labs

R&D activities are characterized by experimentation, material testing, and process validation on a small scale. Batch sizes are often minimal and variable.

A benchtop oven provides the necessary process control and flexibility for developing proofs-of-concept without the overhead of a production-scale unit.

Quality Control & Assurance (QA/QC) Labs

QA labs routinely perform tests like moisture analysis, burn-in testing, or adhesive curing on a small number of samples taken from a larger production line.

A dedicated benchtop oven ensures consistent and repeatable testing conditions for these critical samples, validating the quality of the entire batch.

University and Educational Labs

Academic and teaching laboratories almost always operate with significant space and budget limitations.

Benchtop ovens offer a practical, cost-effective solution for student experiments and small-scale research projects, providing reliable performance in a compact and accessible format.

Understanding the Trade-offs

To make an informed decision, you must also recognize the inherent limitations of a benchtop design.

Limited Batch Size

The most obvious trade-off is capacity. If your lab anticipates a future need to process larger batches or scale up throughput, a benchtop model will quickly become a production bottleneck.

Constraints on Sample Dimensions

The internal chamber size is a hard physical limit. Labs that need to heat-treat larger parts or components are automatically disqualified from using a benchtop oven, regardless of their batch quantity.

Process Scalability

A process developed in a small benchtop oven may not scale directly to a larger industrial oven without re-validation. The thermal dynamics, airflow, and heat-up rates can differ, potentially affecting results when moving to mass production.

Making the Right Choice for Your Lab

Your decision should be based on a clear-eyed assessment of your current and foreseeable operational requirements.

- If your primary focus is maximum space efficiency and flexibility for varied, small-scale tasks: A benchtop oven is the definitive choice for an R&D or QA lab where floor space is a premium.

- If your primary focus is high-volume sample throughput or processing large components: You must evaluate floor-standing industrial ovens, as a benchtop model will become a significant operational bottleneck.

Ultimately, selecting the right oven is about precisely matching the equipment's scale to your operational reality.

Summary Table:

| Lab Type | Key Benefits | Ideal Use Cases |

|---|---|---|

| R&D Labs | Flexibility for small-scale experiments, precise process control | Material testing, proof-of-concept development |

| QA/QC Labs | Consistent testing conditions, repeatable results | Moisture analysis, burn-in testing, adhesive curing |

| University/Educational Labs | Cost-effective, space-saving, accessible for students | Student experiments, small-scale research projects |

Ready to enhance your lab's efficiency with a tailored benchtop oven? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements precisely. Contact us today to discuss how our benchtop ovens can optimize your space and workflow!

Visual Guide

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is a high-temperature vacuum furnace and where is it commonly used? Essential for Purity in Materials Science

- Why is dual heat treatment required for SnO2 nanoparticles? Optimize Oxidation for Superior Performance

- What role does a high-temperature laboratory oven play in catalyst activation? Boost Surface Area and Performance

- What role do high-precision laboratory ovens play in assessing the energy potential of MSW? Enhancing Biomass Accuracy

- How does a box-type high-temperature furnace contribute to 6Mo stainless steel? Optimize Solution Treatment Now