In essence, a high-temperature vacuum furnace is a highly specialized piece of industrial equipment that heats materials to extreme temperatures within a vacuum-sealed chamber. This combination is critical for preventing contamination and unwanted chemical reactions from atmospheric gases. It is commonly used in advanced materials science, semiconductor manufacturing, and aerospace industries for processes requiring absolute purity and environmental control.

The critical value of a high-temperature vacuum furnace is not just its ability to get hot. Its true power lies in using a vacuum to create an ultra-pure environment, eliminating atmospheric gases that would otherwise contaminate or react with materials during sensitive thermal processes.

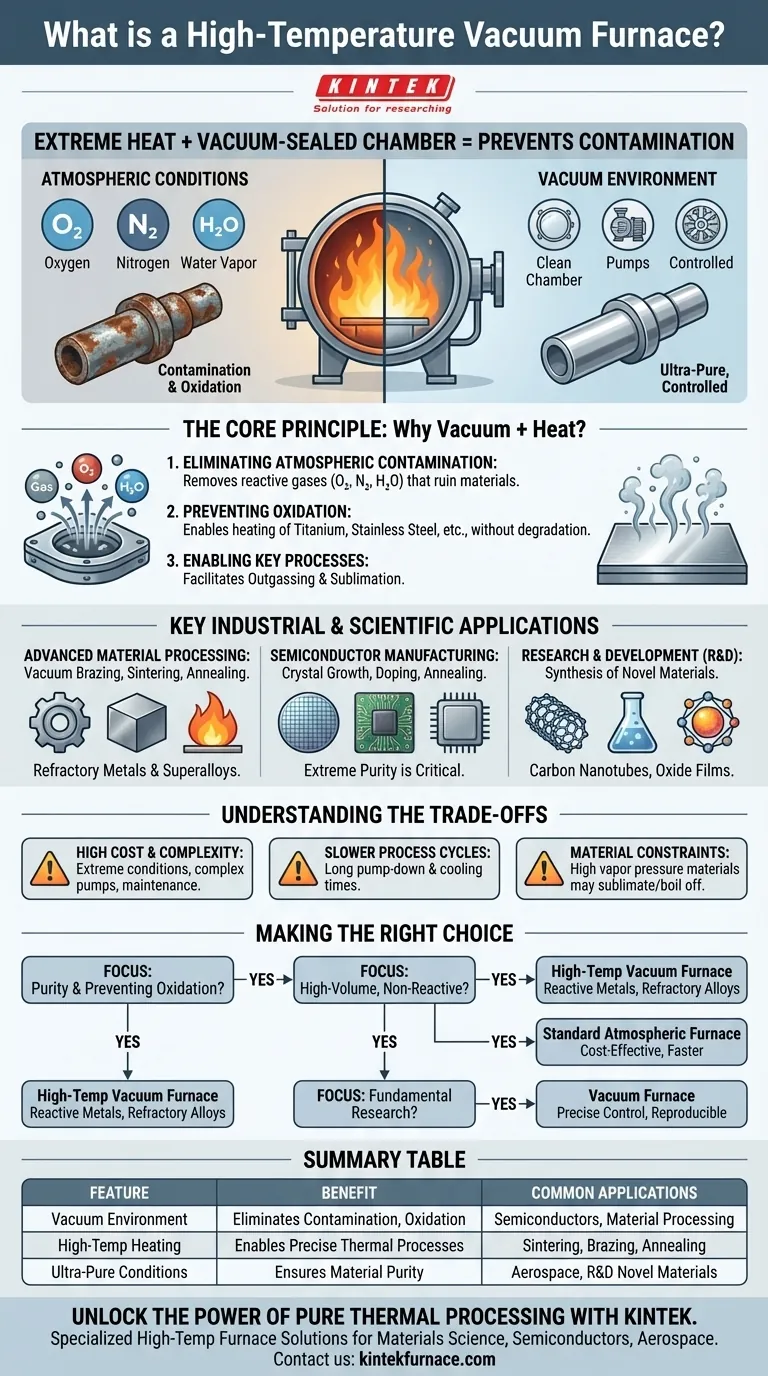

The Core Principle: Why Combine Vacuum and Heat?

To understand the furnace's applications, you must first grasp why the vacuum is as important as the heat. The vacuum is not merely empty space; it is an active tool for controlling the material's environment.

Eliminating Atmospheric Contamination

Standard air contains oxygen, nitrogen, water vapor, and other trace elements. At high temperatures, these gases become highly reactive and can ruin sensitive materials, altering their chemical composition and structural integrity. A vacuum system, using a series of pumps, removes these contaminants to a specified level.

Preventing Oxidation

For most metals, heating in the open air results in the formation of an oxide layer on the surface. This is a form of corrosion that can be detrimental. A vacuum furnace removes the oxygen, allowing materials like titanium, stainless steel, and high-temperature alloys to be heated and joined without degradation.

Enabling Key Physical Processes

A vacuum environment facilitates processes that are difficult or impossible in a normal atmosphere. This includes outgassing, which is the removal of gases trapped within a material's bulk, and sublimation, which is used for purification or thin-film deposition.

Key Industrial and Scientific Applications

The precise control offered by these furnaces makes them indispensable in fields where material performance is paramount.

Advanced Material Processing

Processes like vacuum brazing, sintering, and annealing rely heavily on this technology. Brazing joins components with a filler metal, sintering fuses powdered materials into a solid mass, and annealing alters a material's microstructure to improve its properties. These are essential for creating parts from refractory metals (e.g., tungsten, molybdenum) and superalloys.

Semiconductor Manufacturing

The production of integrated circuits demands extreme purity. High-temperature vacuum furnaces are used for growing silicon crystals, doping wafers with impurities to create transistors, and annealing out defects in the crystal lattice. Even microscopic contamination can render an entire batch of microchips useless.

Research and Development (R&D)

In materials science, these furnaces are foundational tools for discovery. Researchers use them to synthesize novel materials like carbon nanotubes, quantum dots, and specialized oxide films, where the process conditions must be meticulously controlled and reproducible.

Understanding the Trade-offs and Limitations

While powerful, a high-temperature vacuum furnace is not a universal solution. Its benefits come with significant trade-offs that must be considered.

Significant Cost and Complexity

These are not simple ovens. The furnace body must withstand both extreme temperatures and the immense external pressure of the atmosphere. The required vacuum systems, including multiple pumps and precise gauges, add significant cost, complexity, and maintenance requirements.

Slower Process Cycle Times

Achieving a deep vacuum (a process called "pump-down") can take a considerable amount of time. Likewise, cooling the parts within a vacuum is much slower than in air. This results in longer overall cycle times compared to atmospheric furnaces, which can be a bottleneck in high-volume production.

Material Constraints

Not all materials are suitable for processing in a vacuum. Materials with high vapor pressures can sublimate or "boil off" at high temperatures under vacuum. This can contaminate the furnace interior and damage the workpiece itself.

Making the Right Choice for Your Application

Choosing the correct thermal processing method depends entirely on your material, desired outcome, and operational constraints.

- If your primary focus is material purity and preventing oxidation: A high-temperature vacuum furnace is non-negotiable, especially for reactive metals like titanium or refractory alloys.

- If your primary focus is high-volume production of non-reactive materials: A standard atmospheric or controlled-atmosphere (e.g., nitrogen, argon) furnace may be a more cost-effective and faster solution.

- If your primary focus is fundamental research on novel materials: The precise environmental control of a vacuum furnace is essential for creating new structures and achieving reproducible results.

Ultimately, the decision hinges on whether the absolute environmental control provided by a vacuum is a critical requirement for your process.

Summary Table:

| Feature | Benefit | Common Applications |

|---|---|---|

| Vacuum Environment | Eliminates atmospheric contamination and oxidation | Semiconductor manufacturing, material processing |

| High-Temperature Heating | Enables precise thermal processes | Sintering, brazing, annealing |

| Ultra-Pure Conditions | Ensures material purity and integrity | Aerospace components, R&D for novel materials |

Unlock the Power of Pure Thermal Processing with KINTEK

Are you working with sensitive materials that demand absolute purity and precision? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a comprehensive product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether you're in materials science, semiconductor production, or aerospace.

Don't let contamination or oxidation compromise your results—contact us today to discuss how our furnaces can enhance your processes and drive innovation in your lab!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability