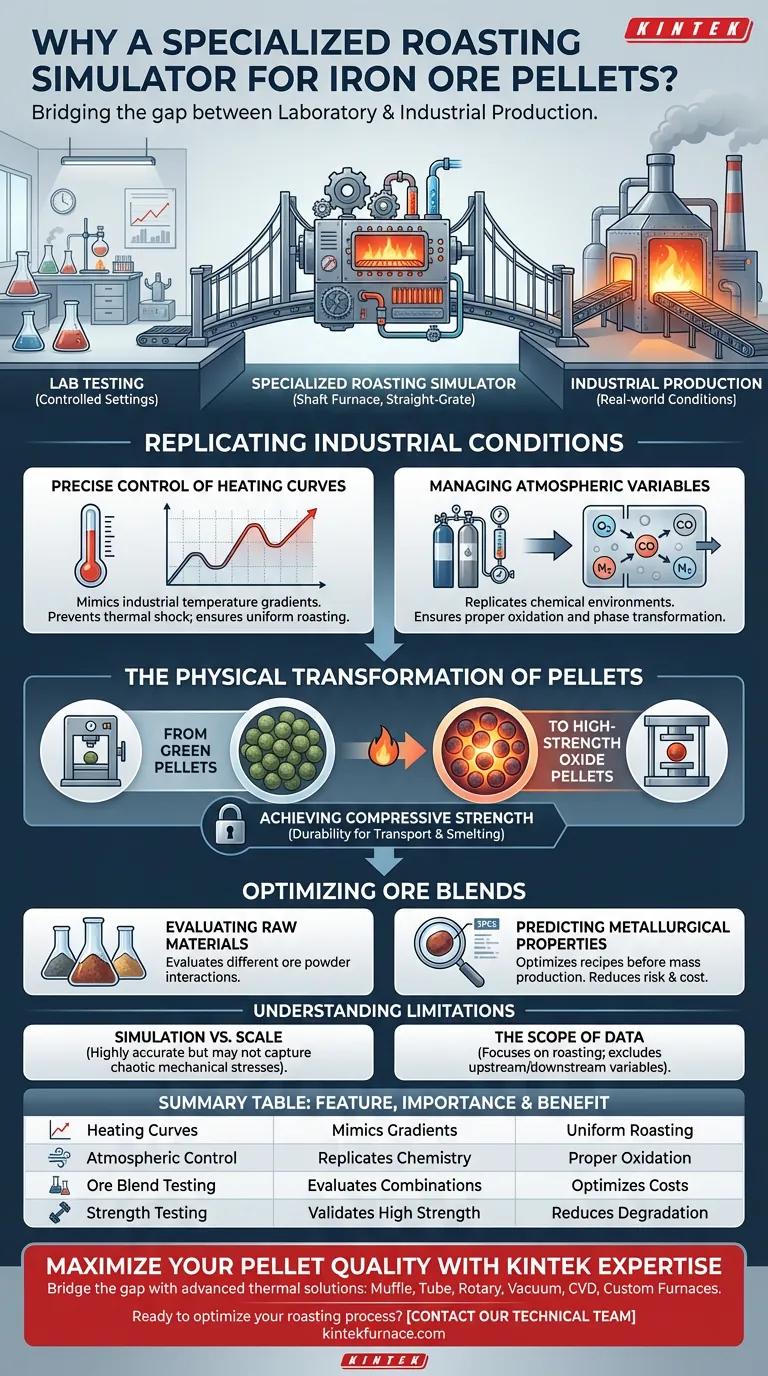

Specialized roasting simulation devices are essential tools for bridging the gap between laboratory testing and industrial production. They are necessary because they accurately replicate the specific thermal and atmospheric conditions of industrial straight-grate roasting. This capability allows engineers to transform raw "green" pellets into high-strength oxide pellets under controlled settings, ensuring the final product meets rigorous strength requirements.

By mimicking exact industrial heating curves and atmospheric conditions, these simulators allow producers to test ore blends and predict metallurgical properties without the risk and cost of full-scale trial runs.

Replicating Industrial Conditions

Precise Control of Heating Curves

Industrial roasting is not a static process; it involves complex temperature gradients. A specialized simulator is required to provide precise heating curves that match these industrial realities.

Without this precision, the thermal shock or heating rate applied to the pellet would not reflect actual production conditions.

Managing Atmospheric Variables

Temperature is only one part of the equation; the chemical environment matters equally. These devices provide rigorous atmospheric control during the roasting process.

This ensures that the oxidation reactions occur exactly as they would in a full-scale shaft furnace or straight-grate system.

The Physical Transformation of Pellets

From Green to Oxide

The primary function of these devices is to facilitate the necessary physical and chemical reactions. They take "green" (raw) pellets and subject them to high temperatures to transform them into oxide pellets.

This phase change is critical for stabilizing the pellet structure before it enters a blast furnace.

Achieving Compressive Strength

The ultimate goal of the roasting process is durability. The simulation ensures the pellets develop high compressive strength.

If a pellet lacks this strength, it will degrade during transport or inside the furnace, leading to inefficiencies.

Optimizing Ore Blends

Evaluating Raw Materials

Producers rarely use a single source of iron ore. These devices are decisive for evaluating how different ore powder blends interact during heating.

Predicting Metallurgical Properties

By running small-scale simulations, engineers can determine the final metallurgical properties of a specific blend.

This allows for the adjustment of recipes to maximize quality before committing to mass production.

Understanding the Limitations

Simulation vs. Scale

While these devices are highly accurate, they remain simulations. They isolate variables in a way that may not capture the chaotic mechanical stresses of a continuously moving industrial grate.

The Scope of Data

The device focuses on the roasting phase specifically. It does not account for upstream variables in mixing or downstream variables in cooling unless specifically configured to do so.

Making the Right Choice for Your Goal

To maximize the value of a roasting simulator, align its use with your specific production objectives:

- If your primary focus is Product Durability: Use the device to rigorously test the compressive strength of pellets under maximum thermal stress.

- If your primary focus is Cost Optimization: Use the device to evaluate cheaper ore powder blends to see if they can maintain metallurgical standards.

These devices ultimately provide the empirical evidence needed to predict industrial performance with confidence.

Summary Table:

| Feature | Importance in Simulation | Benefit to Production |

|---|---|---|

| Heating Curves | Mimics industrial temperature gradients | Prevents thermal shock; ensures uniform roasting |

| Atmospheric Control | Replicates chemical environments | Ensures proper oxidation and phase transformation |

| Ore Blend Testing | Evaluates different powder combinations | Optimizes raw material costs without production risk |

| Strength Testing | Validates high compressive strength | Reduces degradation during transport and smelting |

Maximize Your Pellet Quality with KINTEK Expertise

Bridge the gap between lab research and industrial scale-up with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature lab furnaces—all fully customizable to your unique pelletizing and roasting requirements.

Whether you are refining ore powder blends or testing for maximum compressive strength, our precision-engineered equipment provides the reliable data you need to reduce costs and enhance metallurgical properties.

Ready to optimize your roasting process? Contact our technical team today to discuss your custom furnace needs!

Visual Guide

References

- Wuju Zhang, Congcong Yang. Grinding of Australian and Brazilian Iron Ore Fines for Low-Carbon Production of High-Quality Oxidised Pellets. DOI: 10.3390/min14030236

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do magnesium impurities influence lithium extraction? Accelerate Production with Heterogeneous Nucleation

- How does low-temperature volatilization equipment function? Efficient Electrolyte Removal for Battery Recycling

- What is the role of homogeneous catalysts such as Na2CO3 or KOH in HTL? Boost Bio-crude Yield & Quality

- Why is a high-temperature reaction chamber with a platinum strip used for in-situ XRD analysis of calcium ferrites?

- What role does a laboratory vacuum drying oven play in preparing modified expanded graphite? Ensure Chemical Stability

- How does optimizing fuel gas mass flow affect the thermal efficiency of an industrial furnace? Maximize Heat Retention

- How is a high-stability heating stage used with a fluorescence spectrometer? Evaluate Tb3+/Ce3+ Phosphor Stability

- What is the purpose of using nitrogen cylinders and flowmeters? Ensure Superior Carbon Fiber Recovery