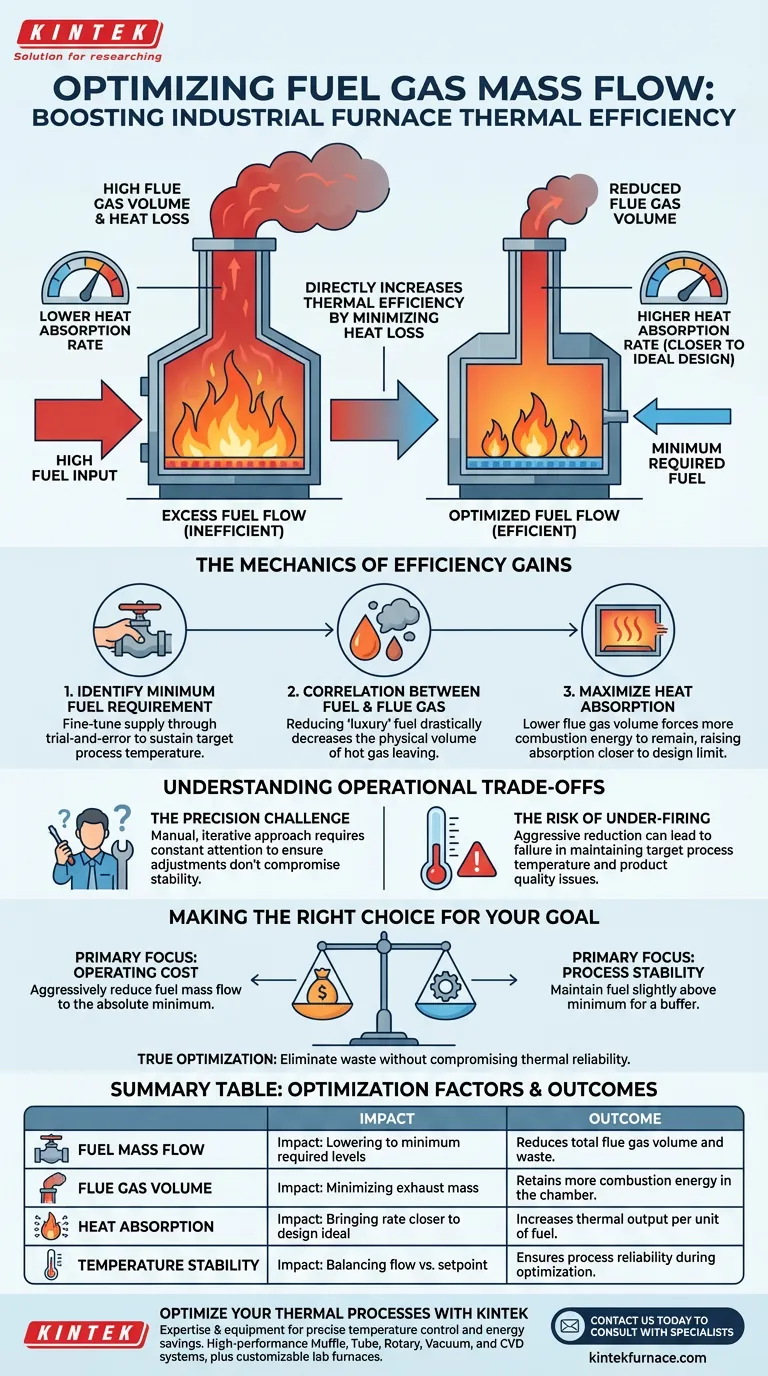

Optimizing fuel gas mass flow directly increases thermal efficiency by minimizing heat loss through exhaust gases. By fine-tuning the fuel supply to the absolute minimum required to maintain your target process temperature, you reduce the total volume of flue gas generated. Because flue gas is the primary vehicle that carries heat out of the furnace, reducing its volume forces a higher percentage of combustion energy to remain in the furnace, raising the heat absorption rate closer to its ideal design value.

Core Takeaway Reducing fuel input isn't just about lowering raw material costs; it is a thermodynamic necessity for high efficiency. By limiting the volume of hot gas exiting the stack, you retain more energy within the chamber, moving the system's actual performance closer to its theoretical maximum efficiency.

The Mechanics of Efficiency Gains

Identifying the Minimum Fuel Requirement

Achieving optimal efficiency requires identifying the minimum fuel supply necessary to sustain the target process temperature.

This is rarely a static calculation; it often requires a process of fine adjustments and trial-and-error.

You must incrementally reduce fuel flow until you find the precise threshold where the temperature remains stable without excess input.

The Correlation Between Fuel and Flue Gas

There is a direct physical link between the amount of fuel burned and the volume of flue gas produced.

Every unit of unnecessary fuel adds to the total mass of combustion byproducts that must be vented.

By cutting "luxury" fuel flow, you drastically decrease the physical volume of hot gas leaving the system.

Maximizing Heat Absorption

The thermal efficiency of a furnace is defined by how much generated heat is actually absorbed by the process rather than lost.

When flue gas volume decreases, the proportion of total heat lost through the exhaust stack drops significantly.

This allows the furnace's heat absorption rate to climb closer to its ideal design limit, such as the 91.66% benchmark mentioned in high-efficiency modeling.

Understanding the Operational Trade-offs

The Precision Challenge

While reducing fuel flow is critical, it relies heavily on trial-and-error rather than automated certainty.

This manual or iterative approach demands constant attention to ensure adjustments do not compromise the furnace's ability to hold temperature.

The Risk of Under-Firing

The goal is to find the minimum required fuel, not to starve the process.

If the mass flow is reduced too aggressively in pursuit of efficiency, the furnace will fail to maintain the target process temperature.

This can lead to product quality issues that far outweigh the savings from reduced fuel consumption.

Making the Right Choice for Your Goal

To apply this effectively, you must balance cost reduction with process stability.

- If your primary focus is Operating Cost: Aggressively reduce fuel mass flow to the absolute minimum threshold to lower both fuel spend and waste gas volume.

- If your primary focus is Process Stability: Maintain fuel flow slightly above the theoretical minimum to create a buffer against temperature fluctuations during trial-and-error adjustments.

True optimization occurs when you eliminate waste without compromising the thermal reliability of your operation.

Summary Table:

| Optimization Factor | Impact on Efficiency | Operational Outcome |

|---|---|---|

| Fuel Mass Flow | Lowering to minimum required levels | Reduces total flue gas volume and waste |

| Flue Gas Volume | Minimizing exhaust mass | Retains more combustion energy in the chamber |

| Heat Absorption | Bringing rate closer to design ideal | Increases thermal output per unit of fuel |

| Temperature Stability | Balancing flow vs. setpoint | Ensures process reliability during optimization |

Optimize Your Thermal Processes with KINTEK

Are you looking to maximize the thermal efficiency of your laboratory or industrial operations? KINTEK provides the expertise and equipment needed to achieve precise temperature control and energy savings.

Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces. Whether you need a standard model or a system customizable for your unique research needs, our solutions are designed to help you find the perfect balance between fuel optimization and process stability.

Ready to upgrade your efficiency? Contact us today to consult with our specialists and discover how KINTEK can enhance your lab's thermal performance.

Visual Guide

References

- Budi Nugroho, Al Misqi. Optimization Of Furnace Efficiency In High Vacuum Units: Analyzing Heat Absorption And Loss Methods For Enhanced Fuel Utilization. DOI: 10.61978/catalyx.v1i2.360

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of the annealing process in OLED preparation? Optimize Film Stability and Device Efficiency

- What is the role of hydrate precursors in Mn3O4 nanosheet synthesis? Achieve Atomic-Level Dimensional Control

- What are advanced materials and composites? Unlock Superior Performance for Your Innovations

- Why are specific temperatures of 848 K, 898 K, and 948 K selected for the Thermal Oxidation of Ti-6Al-4V ELI alloy?

- What are the key characteristics of furnaces used in 3D printing sintering? Achieve Precision Sintering for High-Quality Parts

- What is the purpose of adding aluminum in the vacuum distillation process for magnesium? Enhancing Process Stability and Purity

- What are the advantages of HTL reactors for algae? Optimize Biomass Conversion Without Pre-Drying

- How does industrial-scale forging equipment influence the morphology of primary carbonitrides in H13 tool steel?