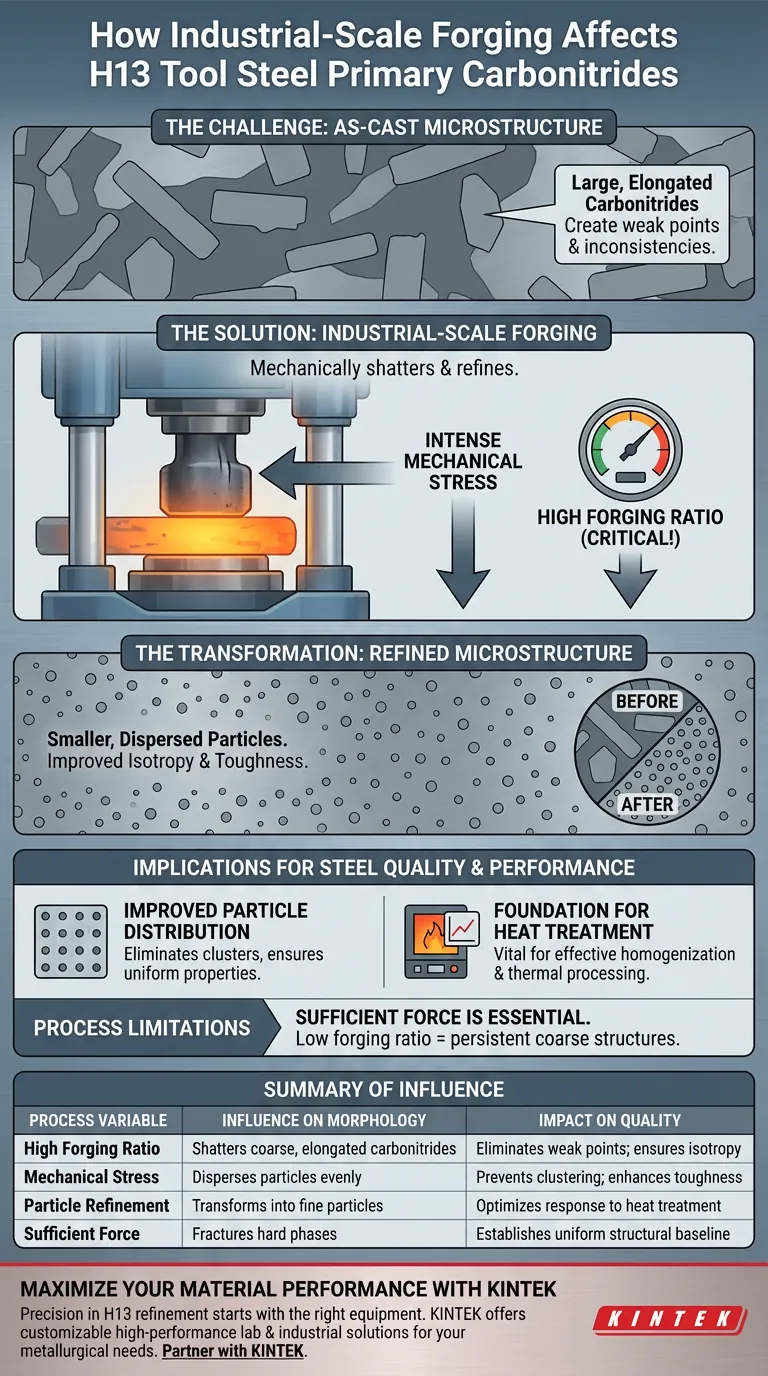

Industrial-scale forging equipment fundamentally alters the microstructure of H13 tool steel through the application of intense mechanical stress. When a high forging ratio is utilized, the equipment effectively shatters the large, elongated primary carbonitrides that naturally develop during the solidification phase. This mechanical intervention transforms these coarse structures into smaller particles and disperses them more evenly throughout the steel matrix.

While solidification naturally results in coarse, irregular carbonitride structures, industrial forging uses mechanical force to refine them into a uniform state. This creates the essential structural baseline required for successful homogenization and heat treatment.

The Mechanics of Morphological Change

Breaking Down Coarse Structures

During the initial solidification of H13 steel, primary carbonitrides tend to form as large, elongated structures. These formations can create weak points or inconsistencies within the material. Industrial forging addresses this by applying sufficient mechanical stress to physically break these large formations down.

The Critical Role of Forging Ratio

The transformation of these particles is not automatic; it depends heavily on the intensity of the process. Specifically, a high forging ratio is required to generate the force necessary to fracture the primary particles. Low-ratio forging may not provide enough energy to significantly alter the morphology of these hard phases.

Implications for Steel Quality

Improving Particle Distribution

The process does more than simply reduce particle size; it reorganizes the internal landscape of the steel. As the large carbonitrides are broken, the forging action distributes the resulting smaller particles throughout the matrix. This eliminates clusters of coarse particles that could compromise the material's isotropy.

Establishing a Foundation for Heat Treatment

Refining the carbonitride morphology is a critical preparatory step. By creating a matrix with smaller, well-distributed particles, the forging process establishes a better structural foundation. This homogeneity is vital for ensuring that subsequent homogenization and heat treatment stages are effective.

Understanding the Process Limitations

The Necessity of Sufficient Force

It is important to recognize that this refinement is purely mechanical and relies on adequate stress application. If the forging equipment cannot achieve a high forging ratio, the elongated carbonitrides will persist. This results in a microstructure that may react unpredictably to heat treatment or suffer from reduced toughness.

Maximizing Material Performance

To ensure the highest quality in H13 tool steel, you must align your forging parameters with your microstructural goals.

- If your primary focus is eliminating microstructural weaknesses: Ensure your equipment is set to a high forging ratio to physically fracture coarse, elongated carbonitrides.

- If your primary focus is optimizing heat treatment response: Prioritize the uniform distribution of particles during forging to create a stable foundation for thermal processing.

By leveraging high-ratio forging, you convert a naturally coarse cast structure into a refined, high-performance material ready for finishing.

Summary Table:

| Process Variable | Influence on H13 Tool Steel Morphology | Impact on Material Quality |

|---|---|---|

| High Forging Ratio | Shatters coarse, elongated carbonitrides into small particles | Eliminates weak points; ensures isotropy |

| Mechanical Stress | Disperses particles evenly throughout the steel matrix | Prevents clustering; enhances toughness |

| Particle Refinement | Transforms large structures into fine, spherical-like particles | Optimizes response to heat treatment |

| Sufficient Force | Physically fractures hard phases during deformation | Establishes a uniform structural baseline |

Maximize Your Material Performance with KINTEK

Precision in H13 tool steel refinement starts with the right equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance lab and industrial solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique metallurgical needs.

Whether you are refining carbonitride morphology or optimizing complex heat treatment cycles, our advanced high-temperature furnaces provide the thermal precision required for superior material isotropy and durability. Partner with KINTEK today to elevate your lab's efficiency and material quality!

Visual Guide

References

- Xiaolin Sun, Shuo Zhao. Effects of Ti and N Contents on the Characteristic Evolution and Thermal Stability of MC Carbonitrides Holding at 1250 °C in H13 Die Steel. DOI: 10.3390/met14030317

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What role does a pyrolysis device play in the synthesis of porous carbon for supercapacitors? Essential Thermal Secrets

- How does a single-roller melt-spinning system facilitate Fe-based amorphous alloys? Achieve Precision Rapid Quenching

- What is the objective of performing an annealing treatment? Enhance Plasticity and Stress Relief for Al-Composites

- What is the significance of preheating UHPC molds? Ensure Safety & Longevity with High-Temp Furnaces

- What are the advantages of using a stainless steel fixed bed reactor for biochar pyrolysis? Unlock Precise Lab Results

- How does a vacuum drying oven contribute to the quality of crosslinked precursors? Expert Guide to Material Integrity

- What are the equipment requirements for THM vs Bridgman? Achieve Ultra-Stable CZT Crystal Growth

- What is the role of sintering in CsPbBr3-SiO2 preparation? Unlock Ultra-Stability with Precise Thermal Sealing