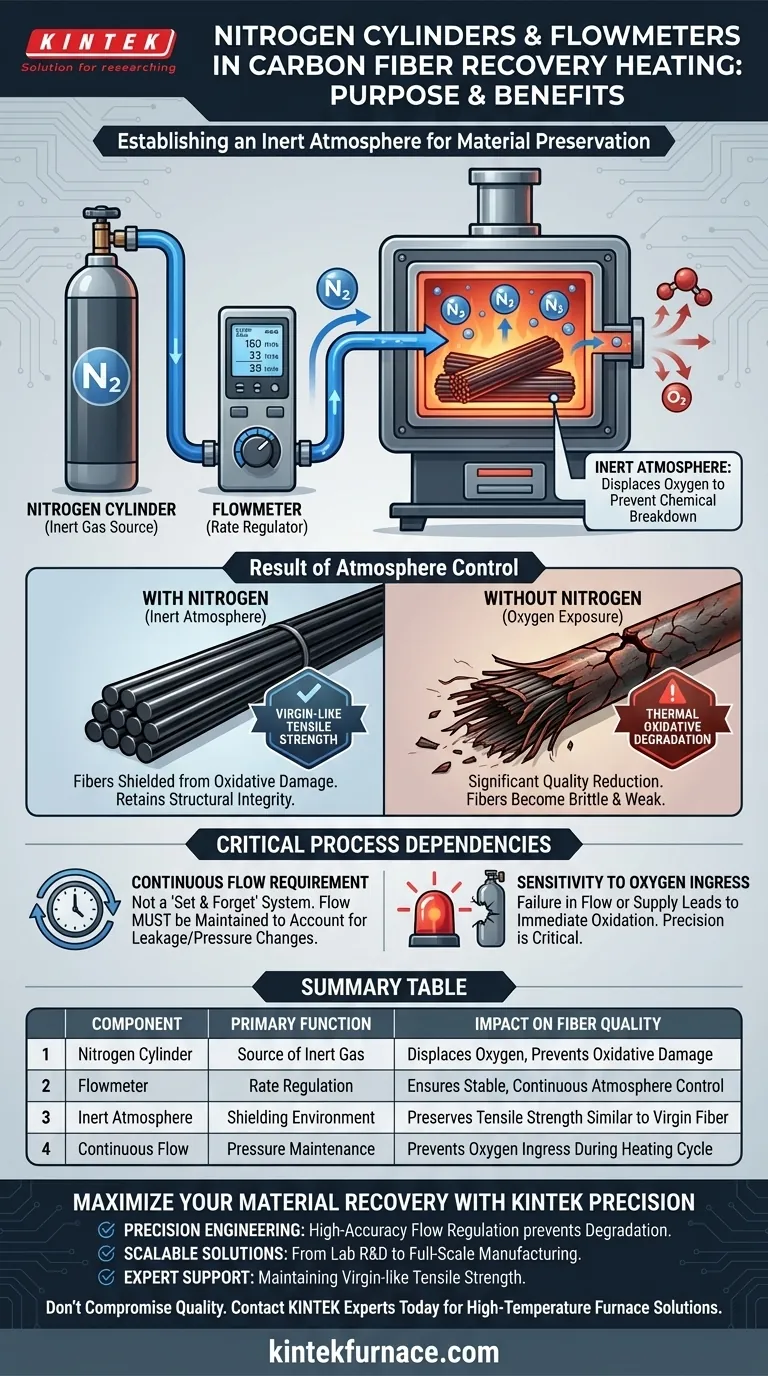

The primary function of nitrogen cylinders and flowmeters in this context is to establish and strictly regulate an inert atmosphere within the reaction chamber. These components work in tandem to continuously inject nitrogen, thereby displacing oxygen during the high-temperature decomposition process.

By excluding oxygen, this setup prevents the chemical breakdown of the fibers. The result is a recovered material that retains a tensile strength nearly identical to that of virgin carbon fibers.

The Mechanics of Atmosphere Control

Creating an Inert Environment

The nitrogen cylinders serve as the source of the inert gas, providing the necessary volume to fill the reaction chamber.

The flowmeters act as the regulatory mechanism, governing the rate at which nitrogen enters the system.

This combination ensures that the environment remains stable and consistent throughout the entire heating cycle.

Preventing Thermal Oxidative Degradation

When carbon fibers are exposed to high temperatures in the presence of oxygen, they undergo thermal oxidative degradation.

This chemical reaction damages the structural integrity of the fiber, significantly reducing its quality.

By continuously injecting nitrogen, the system removes the oxygen required for this degradation to occur.

Preserving Material Properties

The ultimate goal of using this equipment is the preservation of tensile strength.

Because the nitrogen atmosphere shields the fibers from oxidative damage, the recovered fibers do not become brittle or weak.

They emerge from the process with mechanical properties comparable to newly manufactured (virgin) fibers.

Critical Process Dependencies

The Requirement for Continuous Flow

The effectiveness of this system relies entirely on the continuous injection of nitrogen.

This is not a "set and forget" static environment; the flow must be maintained to account for any gas leakage or pressure changes during heating.

Sensitivity to Oxygen Ingress

Any failure in the flowmeters or depletion of the cylinders results in immediate oxygen exposure.

Even brief interruptions in the inert atmosphere during the high-heat stage can compromise the quality of the entire batch.

Therefore, the precision of the flowmeter is just as critical as the purity of the nitrogen source.

Ensuring High-Quality Recovery

To maximize the effectiveness of your carbon fiber recovery process, consider these operational priorities:

- If your primary focus is material strength: Maintain a consistent nitrogen overpressure to guarantee total oxygen exclusion and preserve virgin-like tensile properties.

- If your primary focus is process consistency: Use high-precision flowmeters to monitor the injection rate strictly, preventing fluctuations that could lead to partial degradation.

The successful recovery of carbon fiber is defined not just by the heat applied, but by the oxygen excluded.

Summary Table:

| Component | Primary Function | Impact on Fiber Quality |

|---|---|---|

| Nitrogen Cylinder | Source of inert gas | Displaces oxygen to prevent oxidative damage |

| Flowmeter | Rate regulation | Ensures stable, continuous atmosphere control |

| Inert Atmosphere | Shielding environment | Preserves tensile strength similar to virgin fiber |

| Continuous Flow | Pressure maintenance | Prevents oxygen ingress during the heating cycle |

Maximize Your Material Recovery with KINTEK Precision

Don't let oxygen exposure compromise the integrity of your recovered carbon fibers. At KINTEK, we understand that high-quality results demand rigorous atmosphere control. Backed by expert R&D and manufacturing, we offer advanced Muffle, Tube, Rotary, and Vacuum systems—all fully customizable to your specific carbon fiber processing needs.

Our value to you:

- Precision Engineering: High-accuracy flow regulation to prevent thermal oxidative degradation.

- Scalable Solutions: From lab-scale R&D to full-scale recovery manufacturing.

- Expert Support: Equipment designed to maintain virgin-like tensile strength in your materials.

Ready to enhance your lab's efficiency and material quality? Contact KINTEK experts today to find the perfect high-temperature furnace solution for your application.

Visual Guide

References

- Takaaki Wajima, K. Yamashita. Recovery of carbon fiber from carbon fiber reinforced plastics using alkali molten hydroxide. DOI: 10.1038/s41598-024-84293-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What role does an RTA system play in Zirconia preparation? Master Phase Transformation for Advanced Deposition

- What are the core advantages of using a microwave sintering furnace? Unlock Precision in Al2O3/TiC Ceramics

- What role does a drying oven play in the final preparation of graphite oxide powder? Ensure Material Stability and Purity

- Why is a vacuum drying oven required for the pretreatment of modified zeolite? Preserve Pore Integrity for CO2 Capture

- What is the importance of dynamic sealing in an InP crystal growth furnace? Ensure Pressure Integrity & Motion Control

- What is the primary function of carbonization equipment? Master Biomass to Fuel Conversion with Precision

- What is the technical value of a Hydrogen Reduction-type Test Furnace in green steelmaking? Scale Sustainable Production

- Why is a laboratory vacuum drying oven required for perovskite nanopowders? Safeguard Nanostructure and Purity