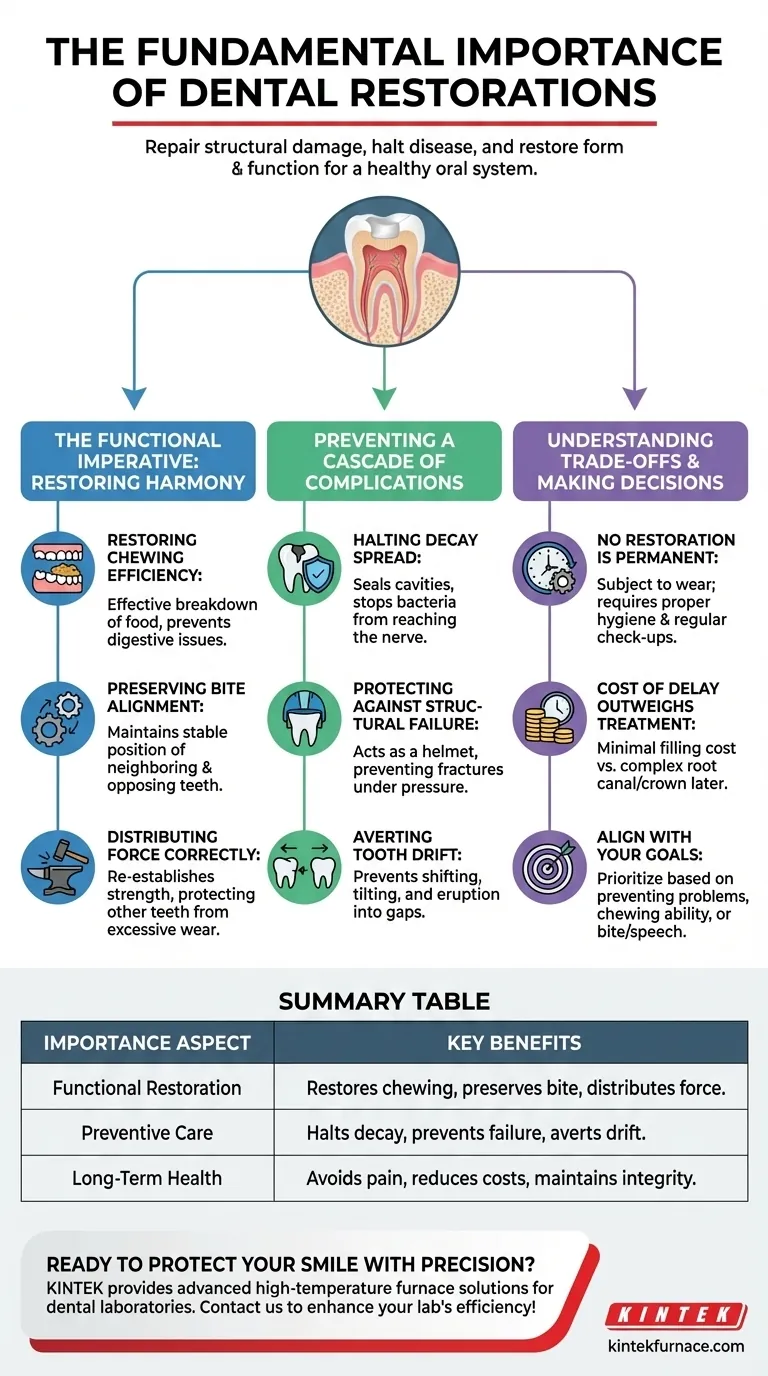

The fundamental importance of a dental restoration is to repair structural damage and halt the progression of disease in a tooth. By doing so, it restores the tooth's original form and function, allowing you to chew and speak properly while preventing pain and averting more complex, costly problems down the line.

A dental restoration is more than a simple repair; it is a critical intervention that preserves the integrity of your entire oral system. Failing to address a single damaged tooth can trigger a cascade of negative consequences, impacting bite alignment, jaw health, and the condition of neighboring teeth.

The Functional Imperative: More Than a Patch

A damaged or missing tooth immediately compromises the precise mechanics of your mouth. A restoration is designed to bring that system back into functional harmony.

Restoring Chewing Efficiency

Your teeth work as a system to break down food. When even one tooth is damaged, cracked, or missing, your ability to chew effectively on that side is diminished, forcing other teeth to carry an uneven load.

This can lead to inefficient chewing, potential digestive issues, and the avoidance of certain healthy foods.

Preserving Bite Alignment

Each tooth holds its neighbors and its opposing tooth in a stable position. A restoration rebuilds this structure.

Without it, a damaged tooth can no longer properly meet the opposing tooth, and adjacent teeth may begin to drift or tilt into the compromised space, disrupting your entire bite.

Distributing Force Correctly

The force of your bite is immense and is meant to be distributed evenly across all of your teeth.

A compromised tooth creates a weak point in this system. A proper restoration re-establishes the tooth's strength, ensuring it can absorb its share of the force and protecting other teeth from excessive wear, chipping, and fractures.

Preventing a Cascade of Complications

The most significant role of a dental restoration is preventative. It stops a small, manageable issue from escalating into a major dental crisis.

Halting the Spread of Decay

A dental filling, the most common restoration, involves removing the decayed portion of a tooth and sealing the cavity.

This physical barrier stops bacteria from penetrating deeper into the tooth, which would otherwise lead to infection of the nerve (requiring a root canal) or total loss of the tooth.

Protecting Against Structural Failure

A cracked or heavily filled tooth is structurally weak. A restoration like a crown acts as a helmet, encasing the tooth to hold it together.

This reinforcement prevents the tooth from fracturing under normal biting pressure, which could otherwise lead to an extraction.

Averting Tooth Drift

When a tooth is lost and not replaced, a predictable chain reaction begins. The teeth on either side of the gap will start to tilt inward, and the tooth above or below it will begin to erupt further out of its socket.

This movement completely disrupts the bite, can create food traps, and makes future restoration more complex.

Understanding the Trade-offs

While essential, it's important to view restorations with a clear understanding of their context and limitations.

No Restoration is a Permanent Solution

Modern dental materials are incredibly durable, but they are not indestructible. Restorations are subject to wear and tear just like natural teeth and will eventually need to be replaced.

Proper oral hygiene and regular dental check-ups are critical to maximizing the lifespan of any restoration.

The Cost of Delay Outweighs the Cost of Treatment

It can be tempting to postpone treatment due to cost or time. However, this is nearly always a mistake.

The cost and complexity of fixing a small cavity with a filling is minimal compared to the cost and time required for a root canal and crown, which is what the problem will likely become if left untreated.

Making the Right Decision for Your Oral Health

Your approach to dental restorations should align with your specific situation and long-term goals for your health.

- If your primary focus is preventing future problems: Treat any diagnosed decay or minor chip immediately. This is the most effective way to avoid pain, infection, and more expensive procedures.

- If your primary focus is restoring chewing ability: Prioritize restorations on your molars and premolars, as these back teeth are responsible for the vast majority of chewing function.

- If your primary focus is correcting your bite and speech: Concentrate on restoring any missing or damaged teeth that have caused a noticeable shift in alignment or impact your pronunciation.

Ultimately, a timely dental restoration is an investment in the long-term stability and health of your entire oral system.

Summary Table:

| Importance Aspect | Key Benefits |

|---|---|

| Functional Restoration | Restores chewing efficiency, preserves bite alignment, and distributes biting force evenly. |

| Preventive Care | Halts decay spread, prevents structural failure, and averts tooth drift and complications. |

| Long-Term Health | Avoids pain, reduces future treatment costs, and maintains overall oral system integrity. |

Ready to protect your smile with precision? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs for dental restorations. Contact us today to enhance your lab's efficiency and ensure superior outcomes for your patients!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations