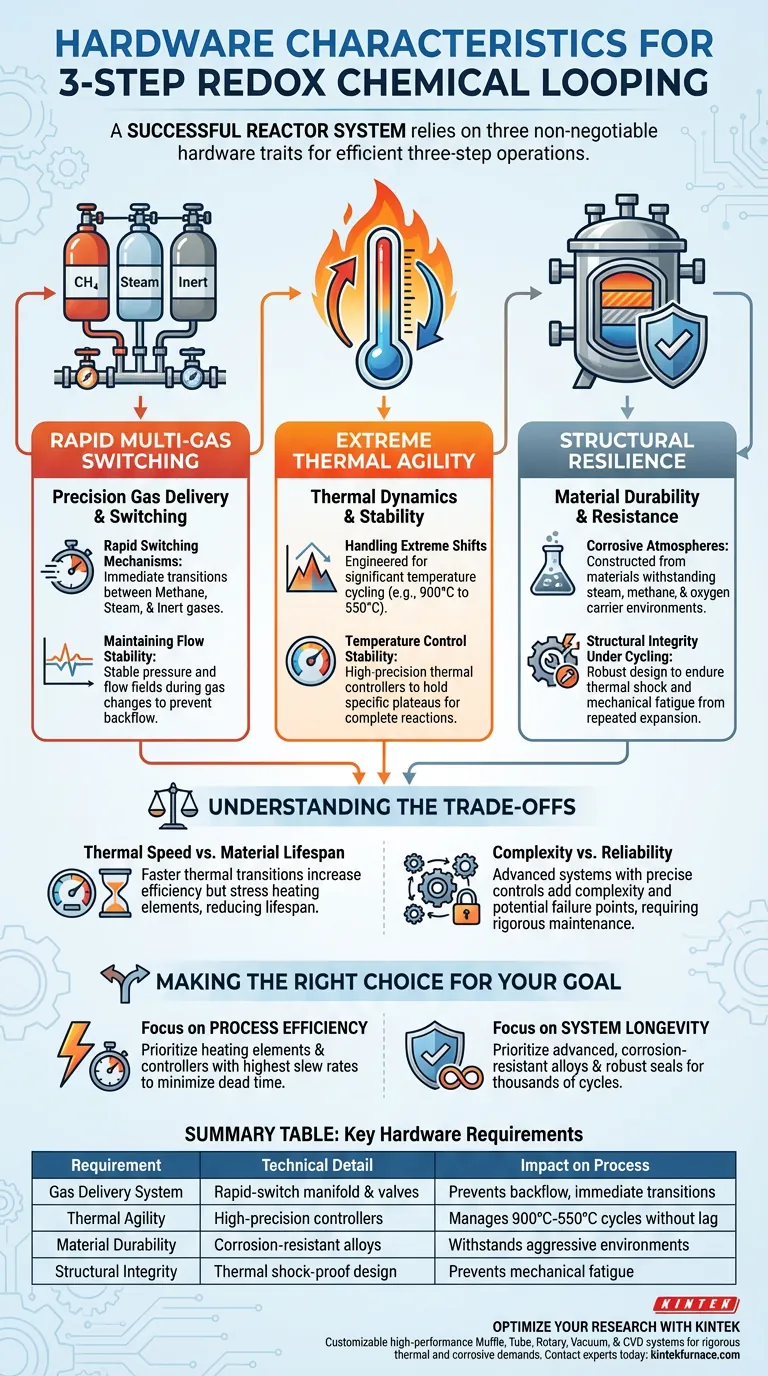

A successful reactor system for three-step redox operations relies on three non-negotiable hardware traits: rapid multi-gas switching, extreme thermal agility, and structural resilience against corrosion. The system must seamlessly transition between methane, steam, and inert gases while managing aggressive temperature shifts, such as dropping from 900 °C to 550 °C, without losing pressure stability.

The core challenge in three-step chemical looping is not just the chemistry, but the physical stress of the cycle. Success depends on hardware that can endure rapid thermal gradients and corrosive environments while maintaining strict separation of process gases through precise flow control.

Precision Gas Delivery and Switching

Rapid Switching Mechanisms

The hardware must incorporate a gas manifold and valve system capable of rapid switching between multiple distinct process gases.

Because the process involves three distinct steps—often utilizing methane, steam, and inert carrier gases—the transition between these inputs must be immediate to maintain process efficiency.

Maintaining Flow Stability

Despite the rapid changes in input gases, the reactor design must ensure stable pressure and flow fields.

Fluctuations in pressure during gas transitions can disrupt the reaction kinetics or cause backflow, making the maintenance of a steady-state flow environment critical during the switching phase.

Thermal Dynamics and Stability

Handling Extreme Temperature Shifts

The reactor hardware must be engineered to accommodate significant and frequent temperature cycling.

A typical cycle may require a shift from methane reduction at a high of 900 °C down to steam oxidation at 550 °C. The heating and cooling elements must be responsive enough to achieve these shifts efficiently without lag.

Temperature Control Stability

Beyond just reaching temperatures, the system requires excellent control stability to hold these specific thermal plateaus.

Drifting temperatures during the reduction or oxidation phases can lead to incomplete reactions or unwanted byproducts, necessitating high-precision thermal controllers and sensors.

Material Durability and Resistance

Resistance to Corrosive Atmospheres

The internal components of the reactor must be constructed from materials capable of withstanding corrosive atmospheres.

The interaction of steam, methane, and oxygen carriers at high temperatures creates an aggressive environment that can rapidly degrade standard reactor materials.

Structural Integrity Under Cycling

The hardware design must account for the physical stress of thermal shock.

Repeatedly cycling between 900 °C and 550 °C causes expansion and contraction that can lead to mechanical fatigue. The reactor vessel and seals must be robust enough to maintain integrity under this constant physical stress.

Understanding the Trade-offs

Thermal Speed vs. Material Lifespan

While rapid temperature changes are necessary for process efficiency, they place maximum stress on the hardware. Pushing for faster thermal transitions often reduces the operational lifespan of heating elements and reactor walls due to thermal fatigue.

Complexity vs. Reliability

Implementing systems for rapid gas switching and precise temperature modulation increases the mechanical complexity of the reactor. This introduces more potential points of failure, requiring a rigorous maintenance schedule to prevent leaks or sensor drift.

Making the Right Choice for Your Goal

To select or design the correct reactor system, align the hardware capabilities with your specific research or production priorities.

- If your primary focus is Process Efficiency: Prioritize heating elements and controllers with the highest slew rates to minimize dead time between the 900 °C and 550 °C setpoints.

- If your primary focus is System Longevity: Prioritize the selection of advanced, corrosion-resistant alloys and robust seals that can endure thousands of thermal cycles without degradation.

Select hardware that turns the volatility of redox cycling into a controlled, repeatable advantage.

Summary Table:

| Key Hardware Requirement | Technical Detail | Impact on Process |

|---|---|---|

| Gas Delivery System | Rapid-switch manifold & valves | Prevents backflow; ensures immediate gas transition |

| Thermal Agility | High-precision thermal controllers | Manages 900°C to 550°C cycles without stability lag |

| Material Durability | Corrosion-resistant alloys & seals | Withstands aggressive steam/methane/oxygen environments |

| Structural Integrity | Thermal shock-proof vessel design | Prevents mechanical fatigue during repeated expansion cycles |

Optimize Your Chemical Looping Research with KINTEK

Transitioning between complex redox steps requires hardware that never compromises on precision or durability. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous thermal and corrosive demands of your specific chemical looping applications.

Ready to build a more resilient lab? Contact our experts today to discuss your custom furnace needs.

Visual Guide

References

- Stefano Scognamiglio, Gianluca Landi. Tunable H <sub>2</sub> /Syngas Production by Chemical Looping Reforming of Methane over La <sub>0.6</sub> Sr <sub>0.4</sub> <i>M</i> <sub>x</sub> <i>M’</i> <sub>1‐x</sub> ( <i>M</i> , <i>M’</i> = Fe, Mn, Co)O <sub>3</sub> Perovskites. DOI: 10.1002/cctc.202500554

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a vacuum storage environment necessary for solid polymer electrolyte films? Ensure Film Integrity & Data Accuracy

- What are the advantages of using a nitrate salt bath furnace? Superior Quenching for Sorbitic Steel Wire

- Why is a fusion process using lithium metaborate necessary for the elemental analysis of S53P4 bioactive glass?

- Why is the use of a vacuum oven mandatory for drying Ti3C2Tx MXene precursors? Protect Your Advanced 2D Materials

- What type of furnaces are commonly used for sintering? Choose the Right Furnace for Your Process

- How does an infrared rapid thermal annealing belt furnace affect battery performance? Maximize Efficiency Today

- Why is an industrial electric drying oven required for catalyst support precursors? Secure Pore Integrity

- How does high-temperature calcination affect kaolin? Boost Surface Area and Catalytic Reactivity via Thermal Processing