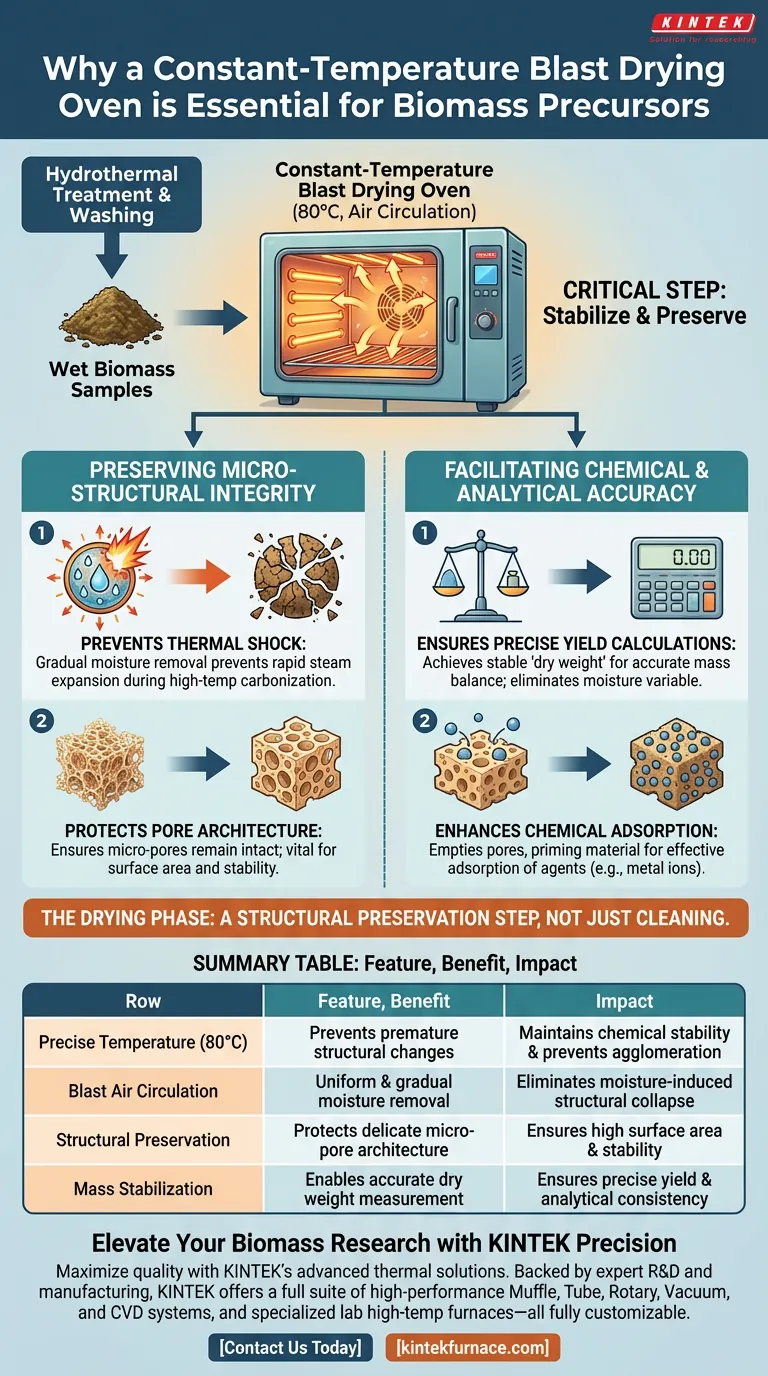

A constant-temperature blast drying oven is a critical processing tool used to stabilize solid biomass samples following hydrothermal reactions and washing. By maintaining a controlled environment, typically at 80 °C, this equipment ensures the complete removal of moisture, which is a prerequisite for protecting the material's physical structure and ensuring analytical precision.

The drying phase is a structural preservation step, not just a cleaning step. It prevents the catastrophic damage caused by rapid steam expansion during subsequent high-temperature carbonization and ensures the mass accuracy required for calculating material yield.

Preserving Micro-Structural Integrity

Preventing Thermal Shock

The primary function of the blast drying oven is to eliminate water gradually before the material is subjected to extreme heat.

If residual moisture remains within the biomass, the high temperatures of subsequent carbonization will cause that water to vaporize instantly. This rapid expansion can shatter the delicate micro-porous structure of the precursor.

Protecting Pore Architecture

The utility of biomass precursors often lies in their porosity.

Thorough drying ensures that the micro-pores remain intact rather than collapsing or bursting due to internal pressure. Preserving this architecture is vital for the material's future performance, particularly regarding its surface area and stability.

Facilitating Chemical and Analytical Accuracy

Ensuring Precise Yield Calculations

To determine the efficiency of the hydrothermal process, you must calculate the material yield.

Accurate yield calculation is impossible if the sample contains variable amounts of retained water. A constant-temperature oven ensures the sample reaches a stable "dry weight," eliminating moisture as a variable in your mass balance equations.

Enhancing Chemical Adsorption

While the primary goal is structural protection, thorough dehydration also primes the material for further chemical modification.

By emptying the pores of physical moisture, you ensure the precursor can effectively adsorb other agents, such as metal ions, in later processing stages. If the pores are blocked by water, the material's loading capacity will be significantly reduced.

Understanding the Trade-offs

Temperature Sensitivity

While drying is essential, the temperature must be carefully modulated; the primary recommendation for this specific biomass processing is 80 °C.

Excessive heat during the drying phase can lead to premature structural changes or agglomeration of particles. The constant-temperature feature of the oven is vital to stay within the safe thermal window for the specific biomass being treated.

Atmospheric vs. Vacuum Conditions

It is important to distinguish between a blast drying oven and a vacuum drying oven.

A blast oven relies on hot air circulation, which is effective for general moisture removal at 80 °C. However, for extremely sensitive nanostructures or volatile solvents, a vacuum oven might be required to lower the boiling point and prevent oxidation, though standard biomass processing generally relies on the blast method.

Making the Right Choice for Your Goal

To maximize the quality of your biomass precursor, align your drying parameters with your specific objectives:

- If your primary focus is Structural Integrity: Ensure the drying temperature is kept moderate (e.g., 80 °C) to prevent rapid vaporization from damaging micro-pores during later carbonization.

- If your primary focus is Analytical Precision: Extend the drying duration until the sample weight stabilizes completely to guarantee accurate yield calculations.

Ultimately, the drying step is the foundation of your material's quality, determining whether the porous structure survives to perform its intended function.

Summary Table:

| Feature | Benefit for Biomass Processing | Impact on Material Quality |

|---|---|---|

| Precise Temperature (80°C) | Prevents premature structural changes | Maintains chemical stability and prevents agglomeration |

| Blast Air Circulation | Uniform and gradual moisture removal | Eliminates moisture-induced structural collapse |

| Structural Preservation | Protects delicate micro-pore architecture | Ensures high surface area and stability for future performance |

| Mass Stabilization | Enables accurate dry weight measurement | Ensures precise yield calculations and analytical consistency |

Elevate Your Biomass Research with KINTEK Precision

Maximize the quality and structural integrity of your precursors with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a full suite of high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to your unique processing needs.

Whether you require precise moisture removal or complex carbonization, our equipment ensures your materials achieve their full potential. Contact us today to discover how KINTEK can enhance your lab's efficiency and analytical precision.

Visual Guide

References

- Xing Wang, Long Zhang. Ultrahigh and kinetic-favorable adsorption for recycling urea using corncob-derived porous biochar. DOI: 10.1038/s41598-024-58538-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is encapsulation with hBN or graphene required during TMD annealing? Shielding Your 2D Materials

- Why is it necessary to dry glassware in a 140 °C oven overnight before GTP? Ensure Precise Anhydrous Polymerization

- What is the primary purpose of an industrial blast drying oven for Si/HC-X? Optimize Biomass Material Pretreatment

- What is the significance of the dual-crucible arrangement in NCMCS sulfidation? Enhance Purity and Control

- What type of furnace was chosen for annealing silicon-based materials and what were the key requirements? Discover the Ideal Solution for Precise Heat Treatment

- What are the advantages of using a nitrate salt bath furnace? Superior Quenching for Sorbitic Steel Wire

- What is the importance of preheating the mold? Master Thermal Control for Aluminum Matrix Composites

- What role does thermal processing in a furnace play in phase analysis of kaolin? Optimize Your Catalyst Structure