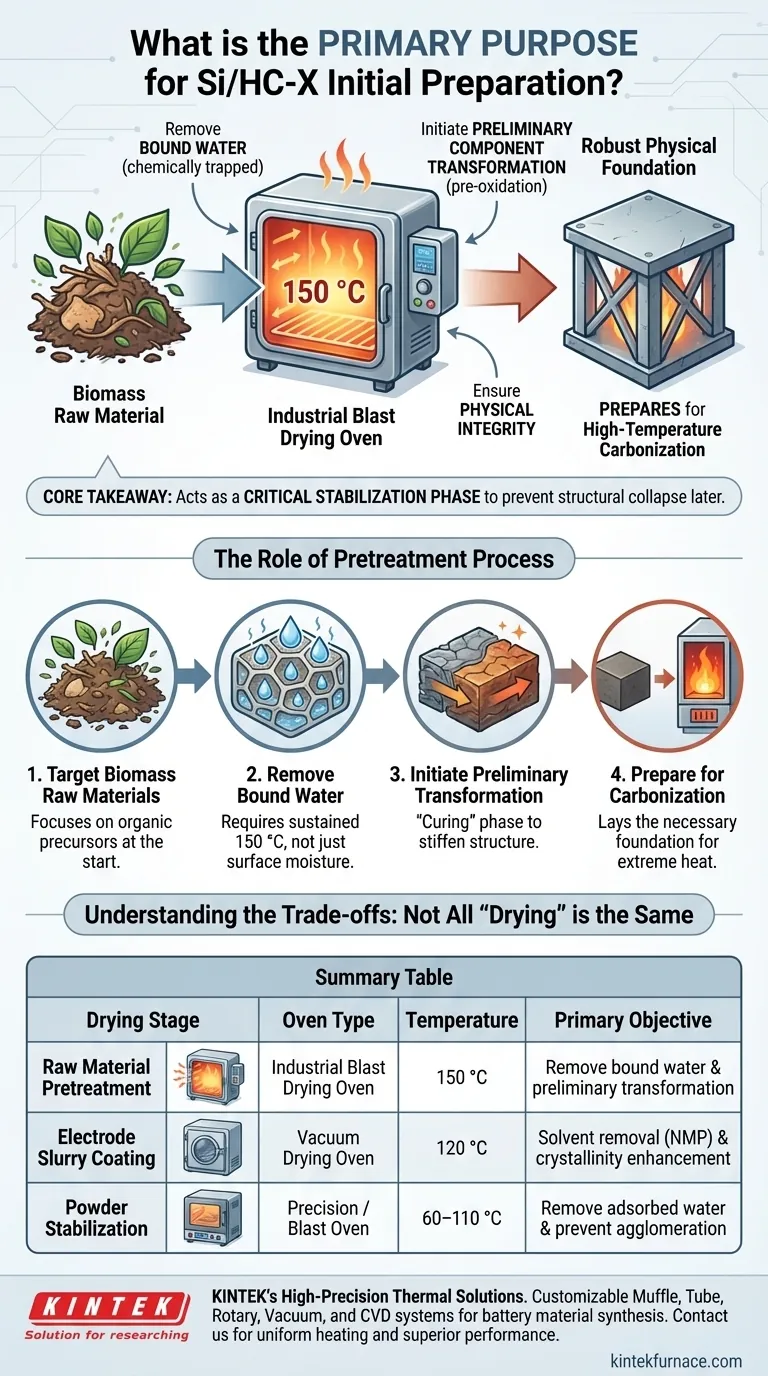

The primary purpose of using an industrial blast drying oven during the initial preparation of Silicon/Hard Carbon (Si/HC-X) composite materials is to treat biomass raw materials at a constant temperature of 150 °C. This process is designed to remove bound water from the biomass and initiate a preliminary component transformation, ensuring the physical integrity of the material before it undergoes high-temperature carbonization.

Core Takeaway This stage acts as a critical stabilization phase. By removing bound water and starting low-temperature transformation now, you create a robust physical foundation that prevents structural collapse or defects during the more aggressive carbonization steps that follow.

The Role of Pretreatment in Si/HC-X Synthesis

Targeting Biomass Raw Materials

The industrial blast drying oven is specifically utilized for the biomass raw materials at the very beginning of the synthesis workflow.

Unlike later stages that treat coated slurries or precipitates, this step focuses on the organic precursors.

Removing Bound Water

The specific goal at this stage is the removal of bound water, not just surface moisture.

Bound water is chemically or physically trapped within the cellular structure of the biomass. Removing it requires the sustained, elevated thermal environment (150 °C) provided by the blast drying oven.

Initiating Preliminary Transformation

Beyond simple drying, this step serves as a "pre-oxidation" or preliminary curing phase.

Exposure to 150 °C begins the component transformation of the biomass. This controlled modification stiffens the material structure, ensuring it maintains its physical form when subjected to extreme heat later.

Preparing for Carbonization

The ultimate goal of this drying phase is to lay a necessary foundation for high-temperature carbonization.

If the biomass is not properly pre-treated and solidified at this lower temperature, the subsequent rapid heating during carbonization could lead to uncontrolled shrinkage or structural failure.

Understanding the Trade-offs and Distinctions

Pretreatment vs. Solvent Removal

It is critical not to confuse this initial biomass treatment with the drying of electrode slurries.

Slurry drying typically uses a vacuum drying oven at 120 °C to remove solvents like NMP and align molecules. The industrial blast oven process discussed here occurs much earlier and operates at atmospheric pressure to treat the raw material itself, not the coating.

Temperature Specificity

The operating temperature of 150 °C is a precise parameter for this specific material.

Lower temperatures (e.g., 60 °C or 110 °C), often used for drying precipitates or filtered powders to prevent agglomeration, are insufficient here. They would fail to remove the tightly bound water or trigger the necessary component transformation in the biomass.

Making the Right Choice for Your Goal

To ensure the structural quality of your Si/HC-X composite, apply the correct drying protocol based on the synthesis stage.

- If your primary focus is Raw Material Integrity: Use an industrial blast drying oven at 150 °C to remove bound water and pretreat the biomass before carbonization.

- If your primary focus is Slurry Coating: Use a vacuum drying oven at 120 °C to remove organic solvents (NMP) and enhance crystallinity.

- If your primary focus is Powder Stabilization: Use a precision or blast oven at lower temperatures (60–110 °C) to remove physically adsorbed water and prevent agglomeration of precipitates.

Success in Si/HC-X synthesis relies on recognizing that "drying" is not a generic step, but a specialized thermal treatment unique to each stage of production.

Summary Table:

| Drying Stage | Oven Type | Temperature | Primary Objective |

|---|---|---|---|

| Raw Material Pretreatment | Industrial Blast Drying Oven | 150 °C | Remove bound water & preliminary transformation |

| Electrode Slurry Coating | Vacuum Drying Oven | 120 °C | Solvent removal (NMP) & crystallinity enhancement |

| Powder Stabilization | Precision / Blast Oven | 60–110 °C | Remove adsorbed water & prevent agglomeration |

Ensure the structural integrity of your Si/HC-X composites with KINTEK’s high-precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of battery material synthesis. Whether you need stable biomass pretreatment or high-temperature carbonization, our lab furnaces deliver the uniform heating required for superior material performance. Contact our experts today to find the perfect furnace for your lab!

Visual Guide

References

- Rajib Samanta, Sudip Barman. Correlating the Sodium Storage Mechanism and Enhancing the Initial Coulombic Efficiency of Biomass‐Derived Hard Carbon in Sodium‐Ion Batteries. DOI: 10.1002/batt.202500295

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why must T91 steel ingots undergo long-term homogenization? Ensure High-Performance Microstructural Uniformity

- What are the main types of heat treatment furnaces? Choose the Right Furnace for Your Lab or Industry

- What is the significance of using a laboratory electric furnace for the quenching and tempering of hull steel? Achieve Precise Microstructure Control

- Why is the use of high-temperature furnace systems critical for delta-MnO2 development? Master Atomic Engineering

- How does the addition of RhCl3 facilitate the synthesis of RhSeCl crystals? Unlock High-Quality Crystal Growth

- What role does a high-temperature heating environment play in the hydrothermal synthesis of ZSM-5 zeolite crystals?

- What are the key characteristics of furnaces used in 3D printing sintering? Achieve Precision Sintering for High-Quality Parts

- Why is thermogravimetric analysis (TGA) necessary for modified hard carbon? Optimize Stability & Composition