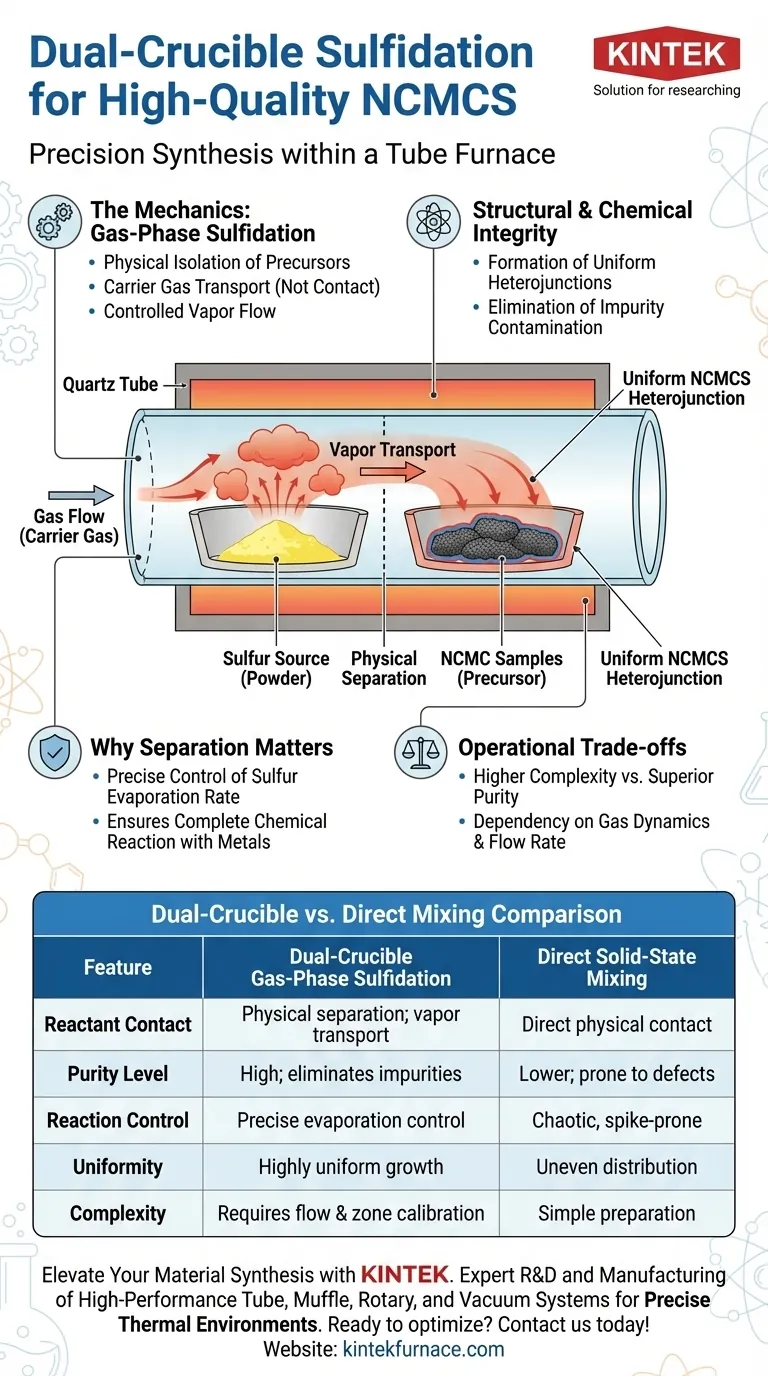

The dual-crucible arrangement is a precise synthesis configuration used to physically separate the sulfur source from the NCMC samples while chemically connecting them through vapor transport. By placing sulfur powder and NCMC samples in distinct ceramic crucibles within a tube furnace, this method utilizes gas flow to carry sulfur vapor over the sample, facilitating a controlled gas-phase sulfidation process rather than a solid-state reaction.

This configuration is the standard for synthesizing high-quality NCMCS because it allows for independent control of the sulfur evaporation rate. This results in the formation of uniform sulfide heterojunctions while eliminating the impurity contamination inevitably caused by direct mixing of raw materials.

The Mechanics of Gas-Phase Sulfidation

Separation of Reactants

The fundamental feature of this arrangement is the physical isolation of the precursors.

Sulfur powder is placed in one ceramic crucible, while the NCMC precursor is placed in another. This prevents the chaotic kinetics associated with direct physical contact between solids.

Vapor Transport Mechanism

Instead of contact heating, the process relies on carrier gas transport.

The heating zone of the tube furnace vaporizes the sulfur. A steady gas flow then transports this sulfur vapor downstream, where it washes over the NCMC sample surface to initiate the reaction.

Why Separation Matters for Material Quality

Precision Control of Evaporation

The dual-crucible setup grants you precise control over the sulfur evaporation rate.

By regulating the heating zone and gas flow, you ensure a steady, consistent supply of reactant. This prevents the "all-or-nothing" reaction spikes common in direct mixing methods.

Ensuring Complete Chemical Reaction

The controlled vapor flow facilitates a thorough reaction with metallic elements.

The sulfur atoms are able to react fully with the nickel and cobalt present in the NCMC sample. This ensures the chemical transformation is complete throughout the material surface.

Structural and Chemical Integrity

Formation of Uniform Heterojunctions

The ultimate goal of this arrangement is structural homogeneity.

The steady supply of gas-phase sulfur promotes the growth of a uniform sulfide heterojunction. This uniformity is critical for the consistent electronic or catalytic performance of the final NCMCS material.

Preventing Impurity Contamination

This method solves the purity challenges of solid-state mixing.

Direct mixing of raw materials often introduces unwanted impurities or defects at the interface. By utilizing gas-phase sulfidation, you effectively eliminate contamination caused by the physical interaction of raw solids.

Understanding the Operational Trade-offs

Complexity vs. Purity

While the dual-crucible method yields superior results, it introduces operational complexity.

Unlike simple mixing, this approach requires careful calibration of gas flow rates and furnace temperature zones to ensure the sulfur vapor reaches the sample at the optimal concentration.

Dependency on Gas Dynamics

The success of the synthesis is heavily dependent on fluid dynamics within the tube.

If the gas flow is too variable, the sulfur distribution may become uneven, potentially negating the uniformity benefits this setup is designed to provide.

Optimizing Your Synthesis Strategy

To determine if this configuration is right for your specific experimental goals, consider the following:

- If your primary focus is High Purity and Uniformity: Adopt the dual-crucible arrangement to ensure a clean heterojunction and avoid physical contamination.

- If your primary focus is Reaction Stoichiometry: Use this setup to precisely control the availability of sulfur vapor relative to the nickel and cobalt content.

- If your primary focus is Rapid, Low-Cost Screening: You might opt for direct mixing, accepting that the resulting material will suffer from lower uniformity and higher impurities.

By decoupling the sulfur source from the substrate, you transform a chaotic mixing process into a controlled surface engineering technique.

Summary Table:

| Feature | Dual-Crucible Gas-Phase Sulfidation | Direct Solid-State Mixing |

|---|---|---|

| Reactant Contact | Physical separation; vapor transport | Direct physical contact |

| Purity Level | High; eliminates raw material impurities | Lower; prone to interface defects |

| Reaction Control | Precise control of sulfur evaporation | Chaotic, spike-prone kinetics |

| Uniformity | Highly uniform heterojunction growth | Uneven structural distribution |

| Complexity | Requires gas flow & zone calibration | Simple preparation |

Elevate Your Material Synthesis with KINTEK

Precision in sulfidation starts with the right equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, and Vacuum systems, all customizable to meet your unique laboratory needs. Whether you are developing NCMCS or advanced heterojunctions, our furnaces provide the stable thermal environments and precise gas flow control essential for high-purity results.

Ready to optimize your synthesis process? Contact us today to discuss your custom furnace requirements with our technical experts!

Visual Guide

References

- Muhammad Ahsan Naseeb, Amir Waseem. Molybdenum carbide supported metal–organic framework-derived Ni, Co phosphosulphide heterostructures as efficient OER and HER catalysts. DOI: 10.1039/d5na00510h

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are batch catalytic debinding ovens used for? Speed Up MIM/CIM with Low-Temp Debinding

- What role does a high-pressure autoclave play in the synthesis of the (NiZnMg)MoN precursor? Achieve Structural Precision

- What is the purpose of pre-baking sapphire substrates? Master Atomic Flatness for Superior Thin Film Growth

- What chemical role does phosphoric acid (H3PO4) play when activating biomass? Master Carbon Material Transformation

- Why is a vacuum drying oven required for processing MXene solutions and NPC@MoS2 nanostructures? Key Benefits Revealed

- What are the primary technical objectives of CoCrFeMnNi alloy annealing? Master Recrystallization & Phase Control

- Why is a two-step process used for waste bone-derived carbon? Unlock Ultra-High Surface Area & Stability

- What are the equipment requirements for THM vs Bridgman? Achieve Ultra-Stable CZT Crystal Growth