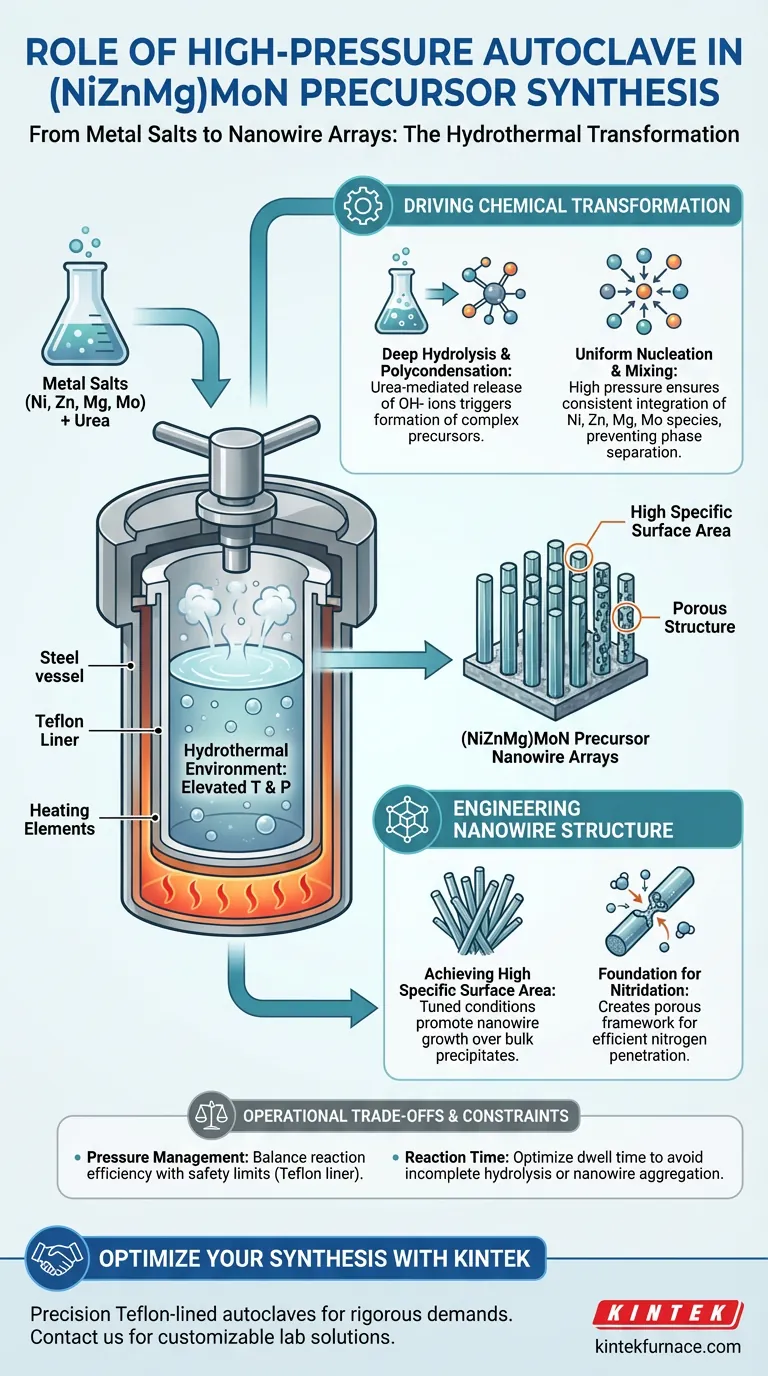

A high-pressure autoclave is the essential reaction vessel that facilitates the hydrothermal transformation of metal salts into a structured (NiZnMg)MoN precursor. By maintaining a closed environment of elevated temperature and pressure, the autoclave enables the deep hydrolysis and polycondensation of nickel, molybdenum, zinc, and magnesium ions. This specific environment is what allows the precursor to develop into a high-surface-area nanowire array rather than a simple bulk precipitate.

The autoclave provides the necessary hydrothermal conditions for urea-mediated hydrolysis and polycondensation, which are critical for synthesizing uniform nanowire arrays. This structural foundation is vital for ensuring the precursor can be effectively nitrided into the final catalytic material.

The Hydrothermal Environment: Driving Chemical Transformation

Facilitating Deep Hydrolysis and Polycondensation

The primary role of the autoclave is to create a controlled, closed system where urea can effectively drive the hydrolysis of metal salts. Under high-temperature and high-pressure conditions, urea decomposes slowly and uniformly, releasing hydroxyl ions that trigger the polycondensation of nickel, molybdenum, zinc, and magnesium. This slow, steady release is far more effective than direct base addition for creating complex, multi-metal precursors.

Promoting Uniform Nucleation and Mixing

The high-pressure environment within the Teflon-lined vessel ensures that metal ions remain thoroughly mixed at the molecular level. This leads to uniform nucleation, where the different metal species (Ni, Zn, Mg, Mo) are integrated consistently throughout the crystal structure. Without the pressure provided by the autoclave, the resulting material would likely suffer from phase separation and inconsistent chemical composition.

Engineering the Nanowire Array Structure

Achieving High Specific Surface Area

The autoclave environment is specifically tuned to promote the growth of nanowire array structures. These arrays provide a massive increase in specific surface area compared to standard particles. This morphological control is a direct result of the hydrothermal growth kinetics enabled by the autoclave’s stable pressure and temperature.

Creating the Foundation for Nitridation

The synthesis of the (NiZnMg)MoN precursor is not the final step, but it is the most critical structural step. The autoclave ensures the precursor has the necessary porosity and surface exposure to undergo subsequent nitridation efficiently. If the precursor structure is too dense or non-uniform, the nitrogen atoms cannot penetrate the lattice effectively during the final processing stage.

Understanding the Trade-offs and Constraints

Pressure Management and Safety

Operating a high-pressure autoclave requires strict adherence to safety protocols and pressure limits. While higher pressures can sometimes improve crystallinity, exceeding the limits of the Teflon liner can lead to contamination or mechanical failure of the vessel. Finding the "sweet spot" between reaction efficiency and equipment safety is a primary operational challenge.

Balancing Reaction Time and Morphological Quality

While the autoclave facilitates the growth of nanowires, dwell time is a critical factor that must be managed. If the hydrothermal process is too short, the hydrolysis may be incomplete; if it is too long, the nanowires may overgrow or aggregate. This aggregation reduces the specific surface area, effectively negating the benefits of using an autoclave in the first place.

How to Apply These Insights to Your Synthesis

When utilizing a high-pressure autoclave for (NiZnMg)MoN precursor synthesis, your operational focus should shift based on your specific material requirements.

- If your primary focus is maximizing surface area: Prioritize precise temperature control to ensure the urea decomposes at a rate that favors thin, high-aspect-ratio nanowire growth.

- If your primary focus is chemical homogeneity: Ensure the autoclave is filled to the appropriate volume to maintain consistent internal pressure, which facilitates the thorough mixing of all four metal ions.

- If your primary focus is scaling production: Invest in multi-well or larger-capacity Teflon-lined autoclaves to maintain the same hydrothermal conditions across larger batches of precursor.

The autoclave is not merely a heater, but a structural architect that dictates the final performance of the (NiZnMg)MoN catalyst through precise environmental control.

Summary Table:

| Key Role | Impact on Precursor Synthesis |

|---|---|

| Hydrothermal Environment | Facilitates urea-mediated hydrolysis and deep polycondensation of Ni, Zn, Mg, Mo ions. |

| Morphology Control | Drives the growth of high-surface-area nanowire arrays instead of bulk precipitates. |

| Molecular Mixing | Ensures uniform nucleation and prevents phase separation of multi-metal species. |

| Structural Foundation | Creates a porous framework optimized for efficient subsequent nitridation. |

Optimize Your Nanomaterial Synthesis with KINTEK

Precision in hydrothermal synthesis requires equipment that delivers unwavering reliability. KINTEK provides high-performance, Teflon-lined autoclaves and high-pressure systems designed to meet the rigorous demands of (NiZnMg)MoN precursor development.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our equipment is fully customizable to ensure your specific temperature and pressure kinetics are met with absolute accuracy.

Ready to elevate your catalytic research? Contact KINTEK today to discuss your unique project needs and discover how our advanced laboratory furnaces can accelerate your innovation.

Visual Guide

References

- (NiZnMg)MoN with optimized d-band center enables industrial-level hydrogen production. DOI: 10.1007/s40843-025-3462-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- Why is pre-sintering of Ga2O3 raw material powder required? Unlock Beta-Phase Stability for High-Performance Thin Films

- Why is a vacuum sealing process necessary for the synthesis of TaAs2 single crystals? Ensuring Purity in CVT Method

- What experimental conditions do physical property measurement systems provide for TaAs2? Explore Cryogenic Transport

- What challenges are associated with batch furnaces? Overcome Inefficiency and Quality Issues

- What is the firing temperature for sintering? A Guide to Material-Specific Ranges

- Why is a high-pressure autoclave essential for nanomaterials? Unlock Superior Crystallinity and Quantum Yield

- What are the advantages of a Vacuum Drying Oven for NiCo2O4 nanosheet composites? Protect Your Nanostructural Integrity

- How does a vacuum environment influence the accuracy of thermoelectric performance measurements for TaAs2? Ensure Precision in Your Research