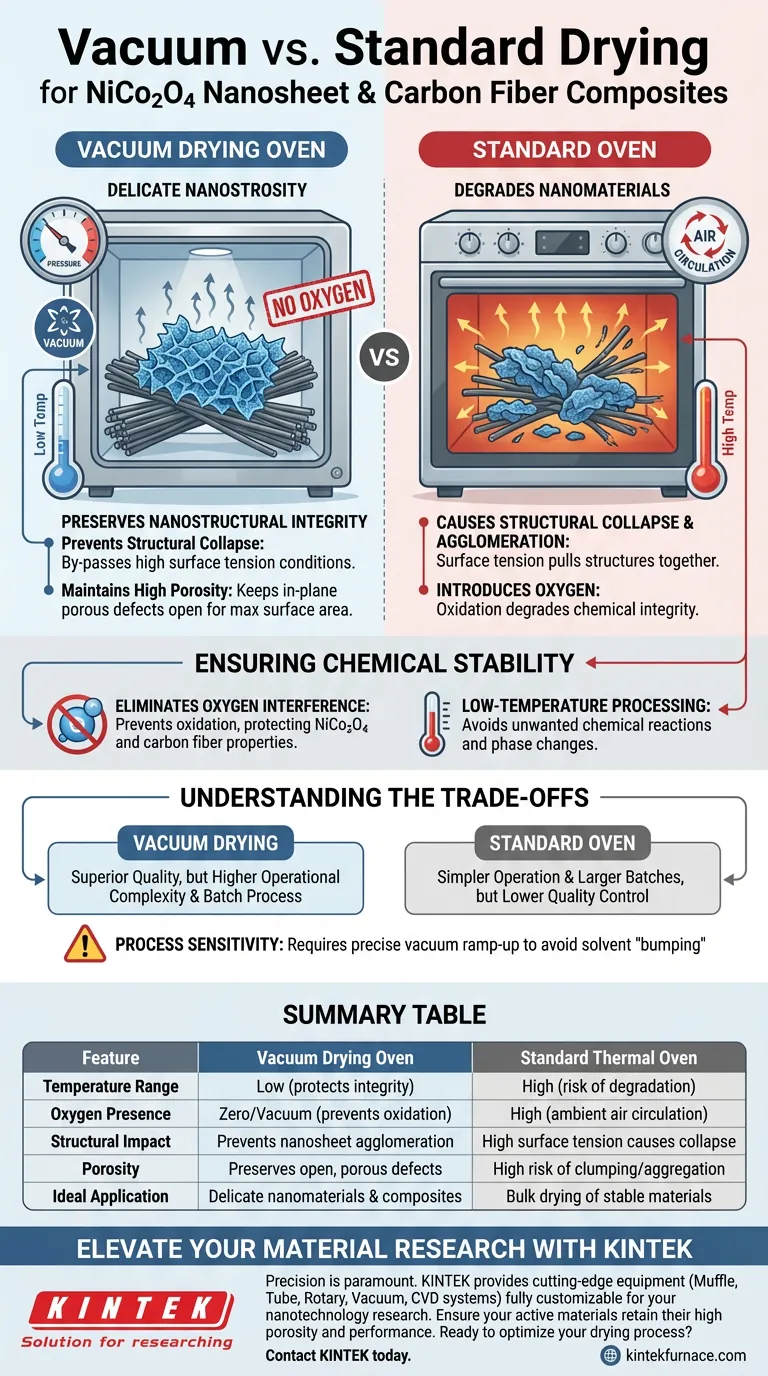

The primary advantage of using a Vacuum Drying Oven lies in its ability to facilitate rapid drying at significantly reduced temperatures while completely eliminating oxygen from the environment. For NiCo2O4 nanosheet and carbon fiber composites, this is critical: it prevents the physical collapse of the delicate nanostructures caused by surface tension and protects the chemical integrity of the active materials from oxidation.

Core Insight Standard thermal drying often degrades nanomaterials through high heat and oxidative stress. Vacuum drying alters the physics of evaporation, allowing moisture removal at low temperatures to preserve the high porosity and "open" structure necessary for maximum material performance.

Preserving Nanostructural Integrity

Preventing Structural Collapse

In a standard oven, the surface tension of evaporating moisture can be strong enough to pull nanoscale structures together.

This force often causes structural collapse or agglomeration, where the nanosheets clump together. Vacuum drying mitigates this by accelerating evaporation at lower temperatures, effectively bypassing the conditions that lead to this structural damage.

Maintaining High Porosity

The specific geometry of NiCo2O4 nanosheets is vital for their function.

Vacuum drying ensures the in-plane porous defects remain open. By preventing severe aggregation, the process guarantees that the nanosheets maintain a high surface area, which is essential for the effective dispersion of active materials on the carbon fiber composite.

Ensuring Chemical Stability

Eliminating Oxygen Interference

Standard ovens circulate air, introducing oxygen to the sample during the heating process.

The vacuum environment removes air entirely, eliminating oxygen interference. This is crucial for maintaining the chemical stability of both the NiCo2O4 precursor and the carbon fiber substrate, preventing unintended oxidation that could degrade the composite's electrical or mechanical properties.

Low-Temperature Processing

High temperatures in standard ovens can trigger unwanted chemical reactions or phase changes.

Because a vacuum lowers the boiling point of solvents, drying occurs at much lower thermal ranges. This protects the chemical composition of the active materials, ensuring that the final product retains the specific properties intended for its application.

Understanding the Trade-offs

Equipment Complexity and Throughput

While vacuum drying offers superior quality control for nanomaterials, it introduces operational complexity.

Standard ovens are generally simpler to operate and can handle larger continuous batches. Vacuum ovens are typically batch-process devices that require careful management of pressure levels and seal integrity, potentially acting as a bottleneck in high-volume manufacturing.

Process Sensitivity

The vacuum environment accelerates solvent evaporation, which is generally positive, but it requires control.

If the pressure drops too suddenly, solvents can boil violently ("bumping"), potentially disrupting the film uniformity on the composite surface. Precise control over the vacuum ramp-up is required to gain the structural benefits without inducing mechanical defects.

Making the Right Choice for Your Goal

To maximize the performance of your NiCo2O4 and carbon fiber composites, align your drying method with your specific material requirements:

- If your primary focus is Surface Area: Use vacuum drying to prevent agglomeration and keep nanosheet pores open for maximum catalytic or electrochemical activity.

- If your primary focus is Chemical Purity: Use vacuum drying to eliminate oxygen and prevent surface oxidation of the carbon fibers and metal oxides.

Summary: The vacuum drying oven is not merely a drying tool; it is a structural preservation device that ensures your nanocomposites retain the porosity and purity required for high-performance applications.

Summary Table:

| Feature | Vacuum Drying Oven | Standard Thermal Oven |

|---|---|---|

| Temperature Range | Low (protects chemical integrity) | High (risk of thermal degradation) |

| Oxygen Presence | Zero/Vacuum (prevents oxidation) | High (ambient air circulation) |

| Structural Impact | Prevents nanosheet agglomeration | High surface tension causes collapse |

| Porosity | Preserves open, porous defects | High risk of clumping/aggregation |

| Ideal Application | Delicate nanomaterials & composites | Bulk drying of stable materials |

Elevate Your Material Research with KINTEK

Precision is paramount when working with advanced NiCo2O4 nanosheets and carbon fiber composites. KINTEK provides the cutting-edge laboratory equipment needed to maintain the chemical purity and structural integrity of your samples.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the unique demands of your nanotechnology research. Don't let structural collapse or oxidation compromise your results—our vacuum systems ensure your active materials retain their high porosity and performance.

Ready to optimize your drying process? Contact KINTEK today to discuss your custom furnace requirements with our technical specialists.

Visual Guide

References

- Xiang Zhang. Facile Synthesis of Mesoporous NiCo2O4 Nanosheets on Carbon Fibers Cloth as Advanced Electrodes for Asymmetric Supercapacitors. DOI: 10.3390/nano15010029

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is a vacuum heating pretreatment system essential for zeolite characterization? Ensure Precise Pore Structure Data

- What is the specific function of laboratory electric heating devices in solid-state hydrogen storage? Optimize Thermal Management

- How does an autoclave assist in modifying bio-carbon with cobalt oxide? Unlock High-Performance Nano-Composites

- How does a vacuum thermal evaporation system ensure the quality of Bismuth Telluride thin films? Expert Insights

- Why is it necessary to connect a pyrolyser online with a GC-MS? Achieve High-Fidelity RDF Analysis

- What are the advantages of zirconia crowns? Achieve Durable, Aesthetic, and Biocompatible Dental Restorations

- Why is an equivalent diffusion combustion heat source term integrated into the furnace temperature field simulation?

- What is the purpose of secondary heating at 200 degrees Celsius for Ge-S-Cd alloys? Ensure Stress-Free Samples