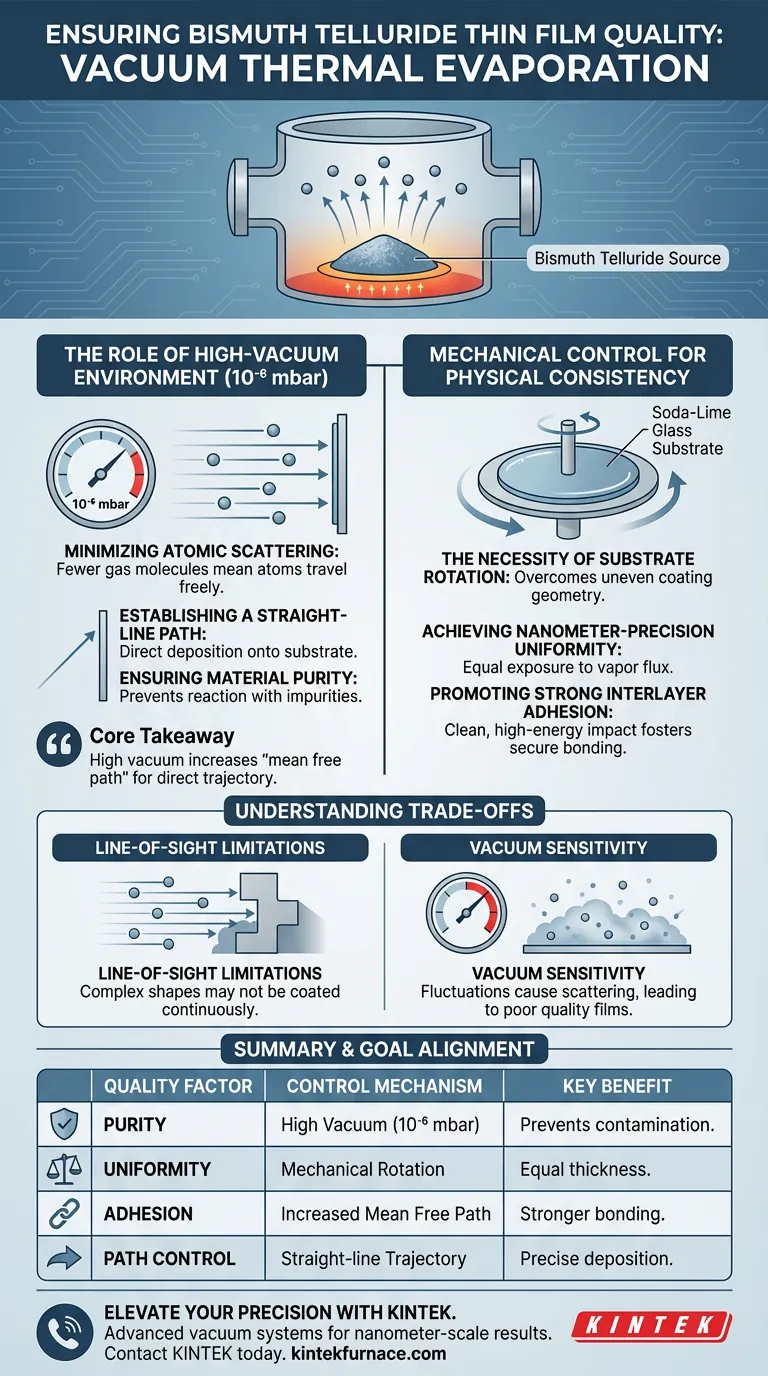

A vacuum thermal evaporation system ensures the quality of Bismuth Telluride thin films by creating a controlled, high-vacuum environment that eliminates physical interference during the deposition process. Specifically, by maintaining vacuum levels such as 10^-6 mbar, the system minimizes the scattering of evaporated atoms, while integrated mechanical rotation ensures the material is distributed evenly across the substrate.

Core Takeaway The quality of Bismuth Telluride films relies on two fundamental principles: a high vacuum to increase the "mean free path" of atoms for a direct trajectory, and substrate rotation to ensure nanometer-scale thickness uniformity and strong adhesion.

The Role of the High-Vacuum Environment

Minimizing Atomic Scattering

The primary threat to thin film quality is the presence of residual gas molecules in the chamber. A vacuum thermal evaporation system counters this by pumping the environment down to high vacuum levels, typically around 10^-6 mbar.

Establishing a Straight-Line Path

In this highly rarefied environment, Bismuth Telluride atoms can travel from the source to the substrate without colliding with gas molecules. This allows the atoms to follow a straight, uninterrupted path, depositing directly onto substrates like soda-lime glass rather than being deflected or scattered.

Ensuring Material Purity

By removing the majority of atmospheric gases, the system prevents the Bismuth Telluride vapor from reacting with impurities during transit. This lack of interference is critical for maintaining the chemical integrity of the deposited layer.

Mechanical Control for Physical Consistency

The Necessity of Substrate Rotation

While the vacuum ensures the material reaches the glass, the geometry of the system can naturally lead to uneven coating. To solve this, high-quality systems are equipped with a rotating substrate holder.

Achieving Nanometer-Precision Uniformity

As the holder rotates, it exposes all areas of the substrate to the vapor flux equally. This mechanical action results in a film with high uniformity, allowing for precise control over thickness at the nanometer scale.

Promoting Strong Interlayer Adhesion

The combination of a clean, high-energy impact (due to lack of scattering) and uniform distribution fosters strong adhesion. The Bismuth Telluride layers bond securely to the soda-lime glass, preventing delamination or weak structural integrity.

Understanding the Trade-offs

Line-of-Sight Limitations

Thermal evaporation is a "line-of-sight" process. Because the atoms travel in straight lines, complex substrate shapes with deep crevices or shadows may not be coated continuously, unlike in gas-phase processes that can flow around corners.

Vacuum Sensitivity

The process is highly sensitive to vacuum fluctuations. If the pressure rises above the optimal 10^-6 mbar range, the mean free path decreases, leading to scattering. This results in "cloudy" or low-density films with poor adhesion and compromised electrical properties.

Making the Right Choice for Your Goal

To ensure the best results when depositing Bismuth Telluride, align your process parameters with your specific quality metrics:

- If your primary focus is Purity: Prioritize the base pressure of the system; ensure it can stably reach and maintain 10^-6 mbar to prevent scattering and contamination.

- If your primary focus is Uniformity: Verify the mechanics of the substrate holder; consistent rotation is non-negotiable for achieving even thickness across the entire glass surface.

- If your primary focus is Adhesion: Monitor both vacuum levels and substrate cleanliness, as the direct impact of unscattered atoms is required for a strong bond.

By strictly controlling the vacuum level and maximizing mechanical uniformity, you convert a chaotic vapor into a precise, high-performance thin film.

Summary Table:

| Quality Factor | Control Mechanism | Key Benefit |

|---|---|---|

| Purity | High Vacuum (10^-6 mbar) | Prevents contamination and gas-phase reactions. |

| Uniformity | Mechanical Substrate Rotation | Ensures equal thickness across the substrate surface. |

| Adhesion | Increased Mean Free Path | Direct, high-energy impact for stronger film bonding. |

| Path Control | Straight-line Trajectory | Eliminates atomic scattering for precise deposition. |

Elevate Your Thin Film Precision with KINTEK

High-performance materials like Bismuth Telluride demand uncompromising deposition environments. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced vacuum systems—including Vacuum, CVD, and customizable high-temp furnaces—designed to deliver the nanometer-scale precision your research requires.

Whether you need to optimize uniformity or achieve deeper vacuum levels, our systems are tailored to your unique lab specifications. Contact KINTEK today to discuss your deposition needs and see how our expertise can drive your results.

Visual Guide

References

- N.G. Imam, Abd El‐Hady B. Kashyout. Comprehensive study of nanostructured Bi <sub>2</sub> Te <sub>3</sub> thermoelectric materials – insights from synchrotron radiation XRD, XAFS, and XRF techniques. DOI: 10.1039/d3ra06731a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the structural advantages of specialized crystal growth furnaces for CZT? Achieve High-Purity Single Crystals

- What is quenching, and why is it important? Achieve Superior Material Hardness and Strength

- What are the advantages of a high-pressure nitrogen environment? Speed and Efficiency in Wood Thermal Modification

- What is the purpose of using a vacuum drying oven for coated carbon cloth? Protect Substrates & Optimize Adhesion

- How does a refining furnace achieve the separation of impurities? Mastering High-Purity White Phosphorus Production

- Why is pressure molding and high-temperature sintering required for UO2-ZrO2? Mastering Material Density

- How does a glove box provide environmental control for Mn2AlB2 precursors? Protect Material Purity & Reaction Accuracy

- Why is precise temperature control programming indispensable for SFC research? Optimize Sintering Process Success