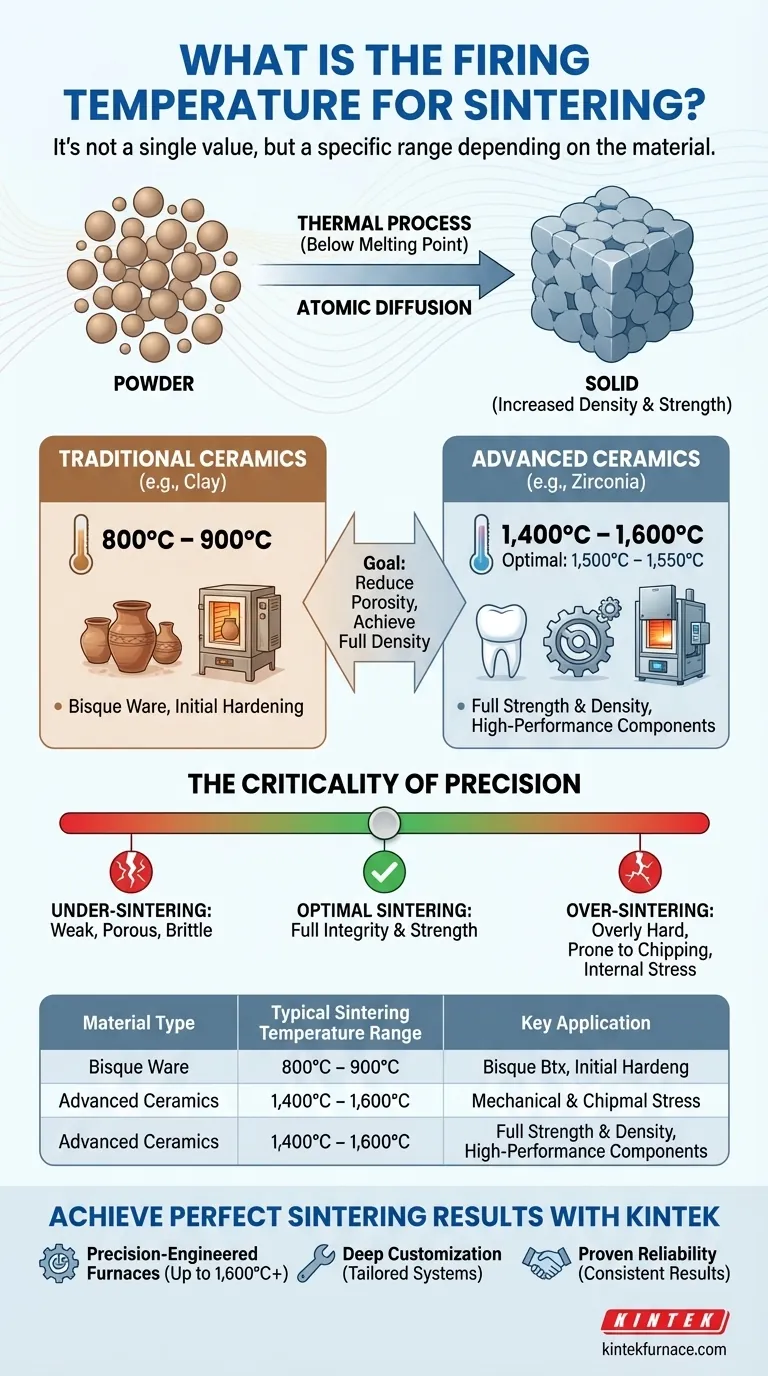

The firing temperature for sintering is not a single value; it is a specific range that depends entirely on the material being processed. For traditional clays, initial sintering to create bisque ware begins around 800–900°C. For high-performance technical ceramics like zirconia, the required temperatures are much higher, typically falling between 1,400°C and 1,600°C to achieve full strength and density.

Sintering is less about hitting a generic temperature and more about executing a precise thermal process. The correct temperature profile is what transforms a collection of loose particles into a dense, strong, and functional solid by activating atomic diffusion without melting the material.

What is Sintering? A Look Beyond Temperature

From Powder to Solid

Sintering is a thermal process that bonds particles together, increasing the density and strength of a material. It occurs at temperatures below the material's melting point.

Imagine a collection of microscopic grains pressed together. When heated, atoms at the contact points between these grains become mobile and diffuse across the boundaries, effectively fusing the particles into a coherent, solid mass.

The Goal: Achieving Full Density

The primary objective of sintering is to reduce or eliminate the porosity (the empty space) between the initial particles. As the particles fuse, these voids shrink and disappear.

A properly sintered part is significantly denser and stronger than its pre-sintered, or "green," state. The temperature is the critical variable that drives the speed and effectiveness of this densification process.

Why Temperature Varies So Drastically by Material

Traditional Ceramics (e.g., Clay)

For materials like clay, the initial phase of sintering begins at relatively low temperatures, around 800°C to 900°C.

At this stage, the clay particles begin to fuse, creating a hard, porous material known as "bisque." This is not full densification but an essential step in creating a durable ceramic body. Full vitrification, which creates a glass-like structure, requires even higher temperatures.

Advanced Ceramics (e.g., Zirconia)

High-performance ceramics like zirconia, used in demanding applications like dental restorations and industrial components, require much more thermal energy to sinter properly.

These materials are fired in furnaces operating between 1,400°C and 1,600°C. Studies show that for zirconia, maximum strength is typically achieved when fired in a narrower window of approximately 1,500°C to 1,550°C.

Understanding the Trade-offs: The Criticality of Precision

The correct temperature is not a suggestion; it is a fundamental requirement for achieving the material's intended properties. Deviating from the optimal range directly compromises the final product's integrity.

Under-Sintering: The Risk of Weakness

Firing at a temperature that is too low or for a duration that is too short results in incomplete sintering.

The particles do not fully fuse, leaving behind significant porosity. This creates a weak, brittle restoration or component that is highly susceptible to fracture under stress.

Over-Sintering: The Risk of Hardness and Chipping

Conversely, firing at a temperature that is too high or for too long can cause over-sintering.

This leads to excessive grain growth within the material's microstructure. While it may sound beneficial, this can make the final part overly hard and paradoxically prone to chipping or cracking, as internal stresses can build up.

Making the Right Choice for Your Goal

The right temperature is part of a complete firing schedule, which also includes the rate of temperature increase (ramp rate) and the duration at peak temperature (hold time).

- If your primary focus is working with traditional clay: A temperature of 800–900°C is your target for the initial bisque firing, which hardens the clay and prepares it for glazing.

- If your primary focus is processing high-strength zirconia: Adhere strictly to the manufacturer's specified range, typically 1,400–1,600°C, aiming for the optimal 1,500–1,550°C window to maximize strength.

- If your primary focus is ensuring maximum material integrity: Always consult the material's technical data sheet for the full firing profile, as temperature, ramp rate, and hold time work together to define the final properties.

Ultimately, mastering the sintering process is about precisely controlling energy to unlock the full potential engineered into your material.

Summary Table:

| Material Type | Typical Sintering Temperature Range | Key Application |

|---|---|---|

| Traditional Clays | 800°C – 900°C | Bisque ware, initial hardening |

| Advanced Ceramics (e.g., Zirconia) | 1,400°C – 1,600°C | Dental restorations, high-strength components |

Achieve Perfect Sintering Results with KINTEK

Mastering the precise thermal profile is critical to transforming powdered materials into strong, dense components. Whether you are sintering traditional clays or advanced technical ceramics like zirconia, the right furnace makes all the difference.

KINTEK delivers the advanced high-temperature solutions your lab needs:

- Precision-Engineered Furnaces: Our Muffle, Tube, Vacuum & Atmosphere Furnaces are designed for exact temperature control and uniform heating up to 1,600°C and beyond.

- Deep Customization: We tailor our systems—including heating elements, insulation, and control software—to match your specific material and sintering profile requirements.

- Proven Reliability: Leverage our in-house manufacturing and R&D expertise to ensure consistent, repeatable results for your most demanding applications.

Ready to optimize your sintering process? Contact our experts today to discuss how a KINTEK furnace can be customized for your unique materials and thermal goals.

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why must the steam-to-carbon (S/C) ratio be strictly controlled? Protect Your Reforming Catalyst and Process

- How does oxygen-enhanced alkaline thermal treatment benefit high-purity cellulose pulp? Achieve Superior Fiber Yield

- What is the importance of transferring freshly deposited CuO films directly into a 125°C oven? Ensure Film Adhesion

- What are the advantages and disadvantages of microwave drying for iron ore briquettes? Expert Process Insights

- How does the heat treatment of NC6 (1.2063) tool steel affect its performance? Key SPIF Tool Optimization

- What is the function of a stainless steel high-pressure reactor in HTC? Optimize Ion-Exchange Resin Conversion

- What are some common applications of industrial furnaces? Discover Key Uses in Manufacturing and Research

- Why is a vacuum sealing process necessary for the synthesis of TaAs2 single crystals? Ensuring Purity in CVT Method