A digital muffle furnace is a high-temperature oven used for precise thermal processing in laboratory and industrial settings. Its primary functions include transforming materials through heat treatment, creating new materials from powders, and analyzing the composition of samples by burning away organic components. The digital control system ensures that these high-temperature processes are accurate, repeatable, and programmable.

A muffle furnace is chosen over a standard oven for its ability to reach extreme temperatures (often over 1000°C) while isolating the sample from the heating elements. This indirect heating prevents contamination, while the digital controls provide the precision required for scientific analysis and advanced material processing.

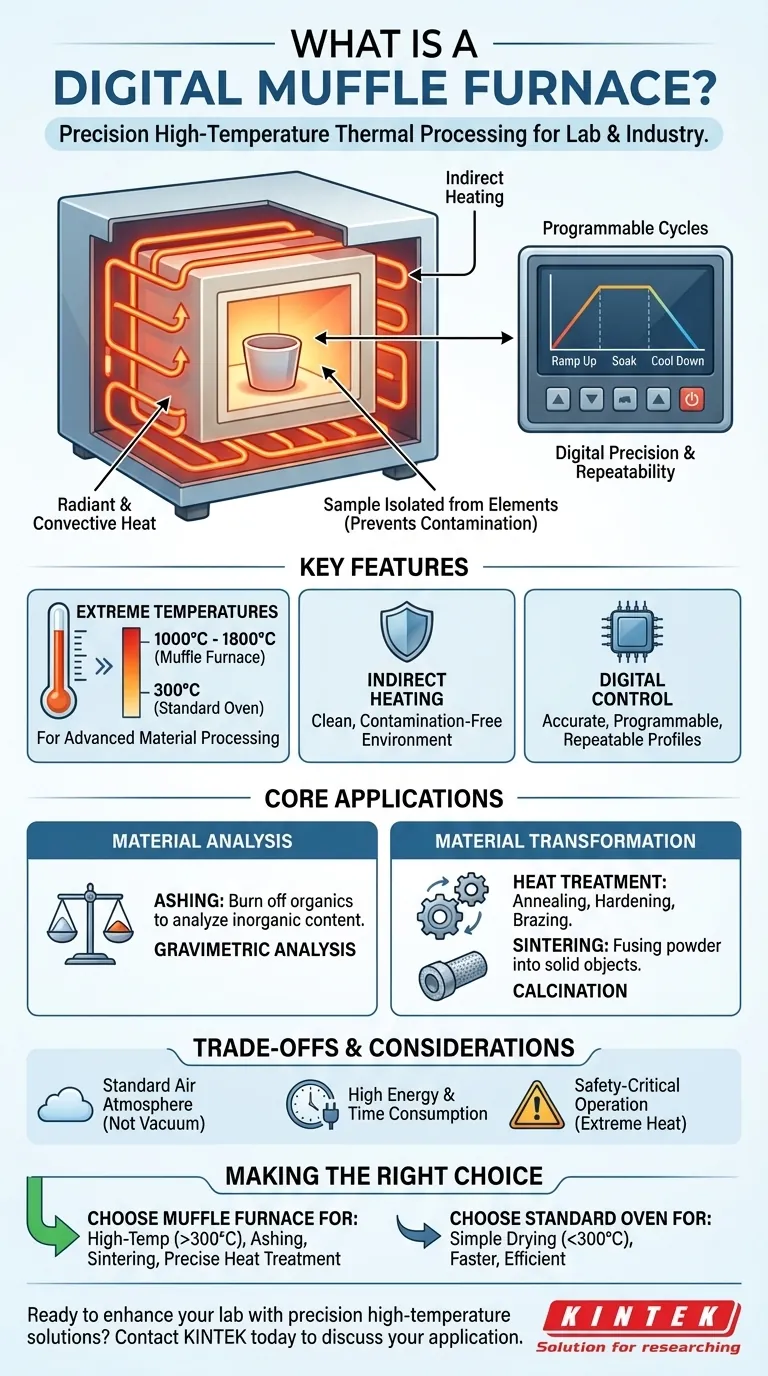

What Makes a Muffle Furnace Unique?

The value of a muffle furnace comes from a combination of three key features: its heating method, its temperature range, and its control system.

The Principle of Indirect Heating

A muffle furnace contains an insulated outer cabinet and an inner chamber, or "muffle," where the sample is placed. The heating elements are located outside this muffle.

This design means the sample is heated by radiation and convection within the chamber, not by direct contact with the heating coils. This separation is critical for preventing contamination of the sample by flakes or impurities from the heating elements.

Achieving Extreme Temperatures

While standard laboratory ovens typically operate up to 300°C (approx. 570°F), muffle furnaces are designed to reach much higher temperatures.

Common models operate between 1000°C and 1200°C (1832°F - 2192°F), with specialized units capable of reaching 1800°C (3272°F) or more for advanced applications with exotic metals and ceramics.

The "Digital" Advantage: Precision and Repeatability

The "digital" aspect refers to the microprocessor-based temperature controller. Unlike simpler analog controls, a digital controller allows for exact temperature setting and superior stability.

Most importantly, it enables programmable heating cycles. Users can define multi-step programs with specific ramping rates (how quickly the temperature rises) and soaking times (how long a temperature is held). This is essential for complex processes and ensures that results are consistent and repeatable.

Core Applications: From Analysis to Creation

The unique capabilities of a digital muffle furnace make it indispensable for processes that fall into two main categories: material analysis and material transformation.

Material Analysis and Testing

The most common analytical use is ashing. In this process, a sample (like food, plastic, or coal) is heated to a high temperature to completely burn off all organic and volatile substances.

The remaining non-combustible material—the ash—can then be weighed or analyzed to determine the inorganic content of the original sample. This is fundamental in quality control, environmental testing, and chemical analysis.

Other analytical uses include gravimetric analysis, volatile matter tests, and testing the durability of materials under extreme heat.

Material Transformation and Synthesis

Muffle furnaces are widely used to permanently change the physical properties of materials.

- Heat Treatment: Metals are heated and cooled under controlled conditions to alter their properties. Processes like annealing (softening metal), hardening, and brazing all rely on the precise temperature control of a muffle furnace.

- Sintering: Fine powders of ceramic or metal are heated to just below their melting point. The heat causes the particles to fuse together, forming a solid, dense object. This is a core process in creating ceramic parts and in powder metallurgy.

- Calcination: Materials are heated to drive off moisture, decompose compounds, or induce a phase transition without melting. This is common in the production of cement and certain catalysts.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool. Understanding its limitations is key to using it correctly.

Not a Vacuum or Atmosphere Furnace

A standard muffle furnace operates with a normal air atmosphere inside the chamber. While it prevents contamination from the heating elements, it does not protect the sample from oxidation or reactions with air.

For processes that require an inert gas environment (like argon or nitrogen) or a vacuum to prevent oxidation, a dedicated vacuum or atmosphere furnace is necessary.

Energy and Time Consumption

Reaching temperatures over 1000°C requires a significant amount of electrical energy. The refractory insulation that allows for these high temperatures also means that heat-up and cool-down cycles can be very long, often taking several hours.

Safety-Critical Operation

The extreme temperatures pose a significant operational hazard. Proper personal protective equipment (PPE), including heat-resistant gloves and face shields, is mandatory. Materials placed inside must be known to be stable at the target temperatures to avoid unexpected reactions or damage to the furnace.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the right tool, consider your primary objective.

- If your primary focus is determining the inorganic content of a sample: You need a muffle furnace for its ability to perform ashing cleanly and at sustained high temperatures.

- If your primary focus is altering the physical properties of metals: A digital muffle furnace provides the precise, programmable control required for heat treatments like annealing or hardening.

- If your primary focus is creating solid parts from ceramic or metal powder: The high, uniform heat of a muffle furnace is essential for the sintering process.

- If your primary focus is simple sample drying below 300°C: A standard laboratory oven is a more efficient, faster, and cost-effective choice.

Choosing a muffle furnace means you are prioritizing high-temperature capability and process purity over speed or atmospheric control.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Indirect Heating | Prevents sample contamination from heating elements. |

| High Temperatures (up to 1800°C) | Enables processes like sintering and advanced heat treatment. |

| Digital Programmable Control | Ensures precise ramping, soaking, and repeatable results. |

| Primary Applications | Ashing, Sintering, Annealing, Calcination, Gravimetric Analysis. |

Ready to enhance your lab's capabilities with a precision high-temperature furnace?

KINTEK's advanced digital muffle furnaces are engineered for accuracy and reliability in your most demanding thermal processes. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust solutions. Our product line, including Muffle, Tube, and Vacuum Furnaces, is complemented by strong deep customization capabilities to meet your unique experimental requirements precisely.

Contact KINTEL today to discuss your application and discover the perfect furnace solution for your lab.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors