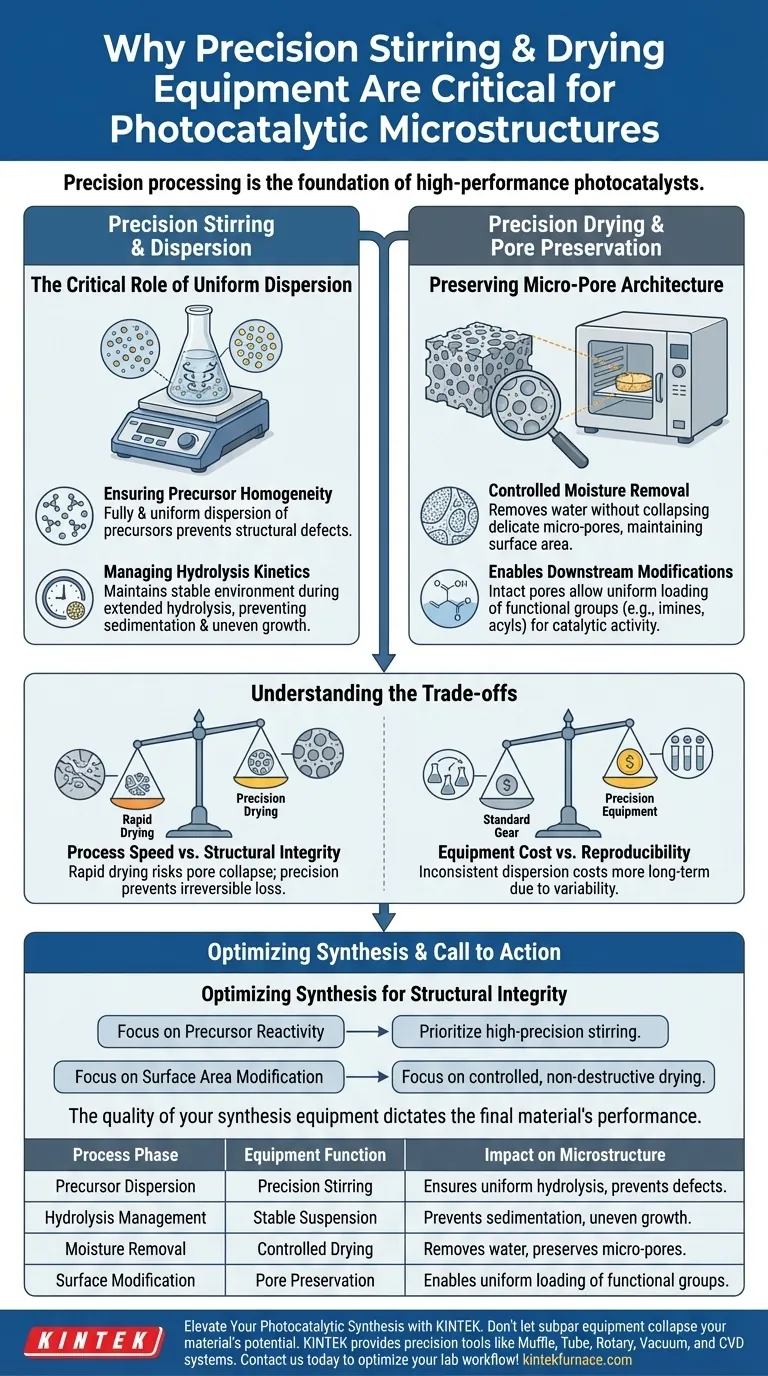

Precision processing is the foundation of high-performance photocatalysts. Precision stirring and drying equipment are not merely operational conveniences; they are critical for maintaining the material's structural integrity during synthesis. Stirring guarantees the uniform dispersion of precursors required for consistent hydrolysis, while specialized drying removes moisture without collapsing the delicate micro-pores necessary for future chemical modifications.

To regulate microstructure effectively, you must strictly control the physical environment of synthesis. Precision equipment ensures that the material's porous architecture remains intact, enabling the uniform loading of functional groups required for catalytic activity.

The Critical Role of Uniform Dispersion

Ensuring Precursor Homogeneity

The primary function of precision stirring is to ensure that precursors are fully and uniformly dispersed within the solvent system. In processes involving pure water, this dispersion is the baseline requirement for a consistent reaction. Without this uniformity, the material develops structural defects at the molecular level.

Managing Hydrolysis Kinetics

Synthesis often requires extended hydrolysis periods, where reactants must remain suspended over long durations. Precision stirring maintains a stable environment throughout this timeframe. This prevents sedimentation or concentration gradients that would otherwise lead to uneven particle growth.

Preserving Micro-Pore Architecture

Controlled Moisture Removal

Once the initial structure is formed, drying processes are employed to remove surface moisture. The challenge here is delicate: the equipment must extract water without damaging the newly formed micro-pores. Aggressive or uneven drying can cause these delicate structures to collapse, destroying the material's potential surface area.

Enabling Downstream Modifications

The preservation of micro-pores is vital for subsequent synthesis steps, such as imine condensation or acylation in ethanol systems. If the pores are intact, functional groups can be uniformly loaded onto the catalyst. If the drying process fails to preserve the pores, these functional groups cannot attach evenly, severely limiting the material's final utility.

Understanding the Trade-offs

Process Speed vs. Structural Integrity

A common pitfall is prioritizing speed over precision during the drying phase. Rapid drying often exerts capillary forces strong enough to crush the micro-pore structure. While precision drying may take longer or require more complex equipment, it prevents the irreversible loss of active surface area.

Equipment Cost vs. Reproducibility

Precision equipment represents a higher initial investment compared to standard laboratory gear. However, the cost of inconsistent dispersion is far higher in the long run. Using standard stirring methods often results in batch-to-batch variability that makes it impossible to scientifically regulate the microstructure.

Optimizing Synthesis for Structural Integrity

Achieving the correct microstructure requires balancing mechanical consistency with thermal delicacy throughout the synthesis workflow.

- If your primary focus is Precursor Reactivity: Prioritize high-precision stirring to ensure total dispersion during the hydrolysis phase.

- If your primary focus is Surface Area Modification: Focus on controlled, non-destructive drying parameters to protect micro-pores for later functional group loading.

Ultimately, the quality of your synthesis equipment dictates the accessible surface area and reactivity of your final photocatalytic material.

Summary Table:

| Process Phase | Equipment Function | Impact on Microstructure |

|---|---|---|

| Precursor Dispersion | Precision Stirring | Ensures uniform hydrolysis and prevents molecular defects. |

| Hydrolysis Management | Stable Suspension | Prevents sedimentation and uneven particle growth during long reactions. |

| Moisture Removal | Controlled Drying | Removes water without collapsing delicate micro-pore structures. |

| Surface Modification | Pore Preservation | Enables uniform loading of functional groups like imines or acyls. |

Elevate Your Photocatalytic Synthesis with KINTEK

Don't let subpar equipment collapse your material's potential. KINTEK provides the precision tools required to maintain structural integrity at the molecular level. Backed by expert R&D and manufacturing, we offer a comprehensive range of customizable solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered for lab high-temperature processing and delicate drying needs.

Whether you are focusing on uniform precursor dispersion or protecting fragile micro-pore architectures for downstream modification, KINTEK has the expertise to support your unique research requirements. Contact us today to optimize your lab workflow!

Visual Guide

References

- Hong Tu, Jian Wu. Unveiling the Impact of Microstructure Alterations on Photocatalytic Hydrogen Peroxide Preparation via <scp>DFT</scp> Prediction and Analysis. DOI: 10.1002/eem2.70016

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does the applicability of materials change with advancements in cracking technology? Unlock New Material Processing Possibilities

- How does a high-precision temperature control system contribute to NMC synthesis? Precision in XRD In-Situ Experiments

- How does high-purity argon gas affect the production of ultrafine magnesium powder in evaporation-condensation methods? Master Particle Size Control

- What role does helium play in nanoparticle synthesis? Unlock Precision via Inert Gas Condensation

- What are the advantages of PVD coating? Achieve Precision, Purity, and Eco-Friendly Performance

- Why is thermal insulation applied to cylindrical components in thermal stress tests? Enhance Calculation Precision

- What are the advantages of using a stainless steel fixed bed reactor for biochar pyrolysis? Unlock Precise Lab Results

- Why is rapid water quenching necessary for Ce2(Fe, Co)17 alloys? Unlock Peak Magnetocaloric Performance