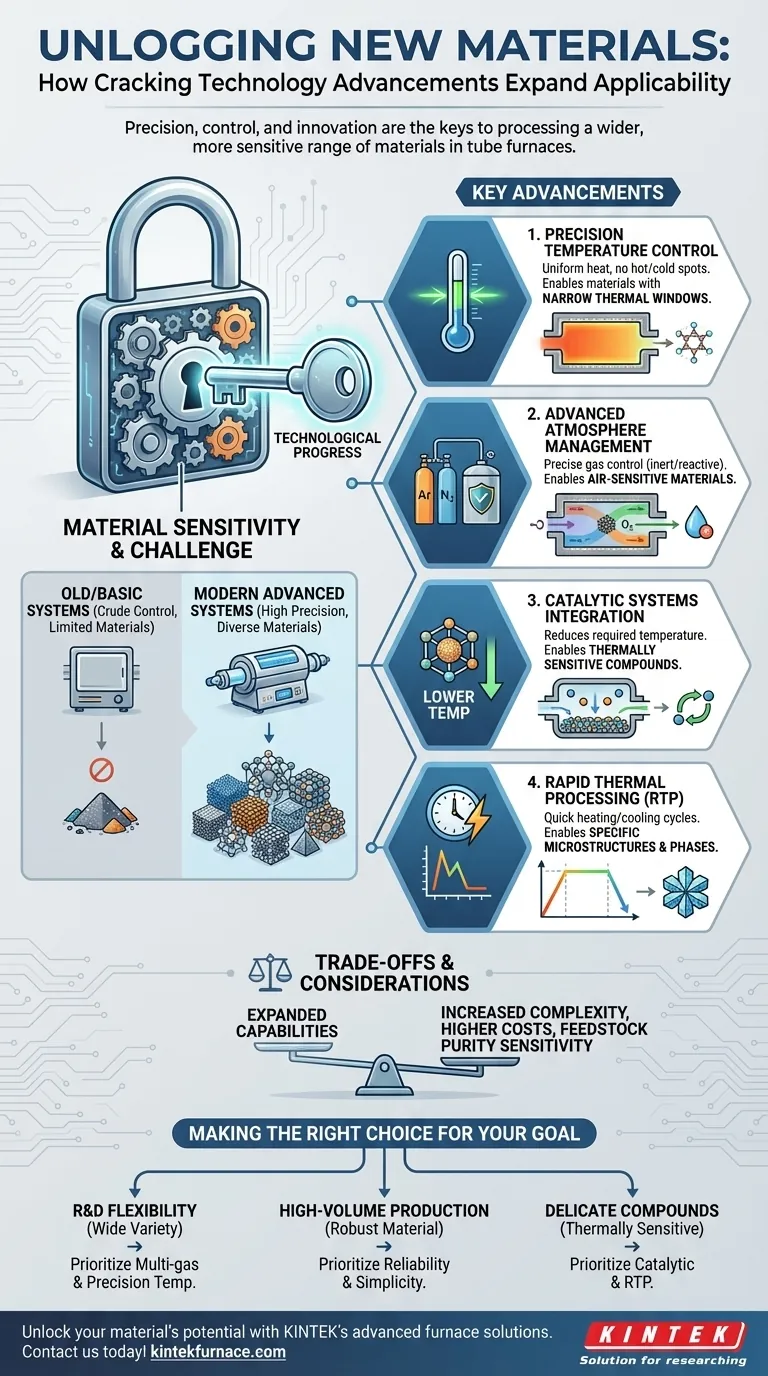

In short, advancements in cracking technology directly and significantly expand the range of materials that can be effectively processed. As the precision and control of the cracking environment improve, processes that were once too difficult or inefficient become viable, opening the door to new material applications in equipment like tube furnaces.

The core issue is not just about applying heat, but about achieving a highly controlled chemical transformation. Technological progress gives us finer control over temperature, atmosphere, and reaction pathways, which is the key to successfully cracking a wider and more sensitive array of materials.

What is Cracking and Why is it Material-Sensitive?

To understand the impact of technology, we must first establish the fundamental challenge. Cracking is a process of breaking down large, complex molecules into smaller, simpler ones, typically using heat.

The Basic Principle: Thermal Decomposition

At its heart, cracking involves supplying enough thermal energy to break chemical bonds within a material. This process is essential in everything from refining crude oil into gasoline to creating precursor materials for advanced manufacturing.

The Challenge of Material Specificity

Different materials have vastly different chemical structures and bond energies. The precise temperature and conditions required to crack one material effectively might completely destroy another or produce undesirable byproducts. This inherent specificity has historically limited which materials could be processed in a given system.

The Tube Furnace as a Controlled Environment

A tube furnace provides the enclosed, controlled environment needed for this transformation. The quality of that control is what dictates its capabilities. Early or basic systems offered crude control, limiting their use to robust and forgiving materials.

How Technological Advancements Unlock New Materials

Modern advancements are not a single breakthrough but a series of improvements that, together, enable unprecedented precision. This precision is what allows us to process a more diverse and sensitive slate of materials.

Precision Temperature Uniformity and Control

Older furnaces often suffered from "hot spots" and "cold spots," leading to inconsistent results. Modern systems provide exceptional temperature uniformity, ensuring the entire material is processed at the optimal temperature. This prevents over-cracking (degradation) in one area and under-cracking (incomplete reaction) in another, making the process viable for materials with a narrow processing window.

Advanced Atmosphere Management

Cracking rarely happens in a simple air environment. The ability to precisely control the process atmosphere—using inert gases like argon to prevent oxidation or introducing reactive gases to guide chemical pathways—is a critical advancement. This allows for the processing of air-sensitive materials that would have been impossible before.

Integration of Catalytic Systems

Perhaps the most significant advancement is the use of catalysts. Catalysts lower the activation energy required for cracking to occur, meaning the process can be run at a much lower temperature. This is a game-changer for thermally sensitive materials that would decompose or degrade at the high temperatures required for traditional thermal cracking.

Rapid Thermal Processing (RTP)

The ability to heat and cool a material very quickly adds another layer of control. Rapid heating can initiate a reaction, and rapid cooling can "quench" it, effectively freezing the material in a desired state before further, unwanted reactions occur. This enables the creation of specific microstructures and metastable phases.

Understanding the Trade-offs

While advancements expand capabilities, they also introduce new considerations. This progress is not without its own set of challenges.

Increased System Complexity

A furnace with precise temperature ramping, multi-gas atmosphere control, and integrated catalytic supports is far more complex than a simple heating chamber. These systems demand more sophisticated operational knowledge and maintenance protocols.

Higher Initial and Operational Costs

Advanced features come at a price. The capital investment for a high-precision tube furnace is significantly greater, and the operational costs associated with high-purity gases and catalyst replacement must be factored in.

Sensitivity to Feedstock Purity

In some cases, advanced processes can be less forgiving. For example, certain catalysts are easily "poisoned" by impurities in the raw material. This can mean that while the technology can handle a new material, it requires that material to be of a much higher and more expensive purity grade.

Making the Right Choice for Your Goal

The right technology depends entirely on your specific objective. Understanding this relationship allows you to invest in the capabilities you truly need.

- If your primary focus is processing a wide variety of R&D materials: Prioritize a system with maximum flexibility, including precise temperature programming and multi-gas atmosphere control.

- If your primary focus is high-volume production of one robust material: A simpler, highly reliable furnace optimized for a single process may be more cost-effective than a feature-rich advanced system.

- If your primary focus is cracking thermally delicate or sensitive compounds: Investigate systems that specialize in catalytic processing or offer rapid thermal processing (RTP) capabilities.

By understanding how technology governs the process, you can make smarter decisions that directly enable your material development and production goals.

Summary Table:

| Advancement | Impact on Material Applicability |

|---|---|

| Precision Temperature Control | Enables processing of materials with narrow thermal windows, preventing degradation |

| Advanced Atmosphere Management | Allows cracking of air-sensitive materials using inert or reactive gases |

| Catalytic Systems Integration | Reduces required temperatures, making it viable for thermally sensitive compounds |

| Rapid Thermal Processing (RTP) | Facilitates creation of specific microstructures and phases through quick heating/cooling |

Unlock the full potential of your material processing with KINTEK's advanced high-temperature furnace solutions. Our expertise in R&D and in-house manufacturing delivers products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization to meet your unique experimental needs. Contact us today to discuss how we can enhance your lab's efficiency and precision!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety