The primary challenges of batch furnaces are rooted in their operational design, leading to significant hurdles in processing time, temperature uniformity, and overall efficiency. These systems require individual processing for each load, demand manual handling, and consume extra energy, all of which can impact production quality and cost.

While excellent for flexible, low-volume, or varied production runs, batch furnaces introduce inherent inefficiencies in time, energy, and process consistency. Understanding these trade-offs is critical when evaluating them against continuous processing alternatives for your specific application.

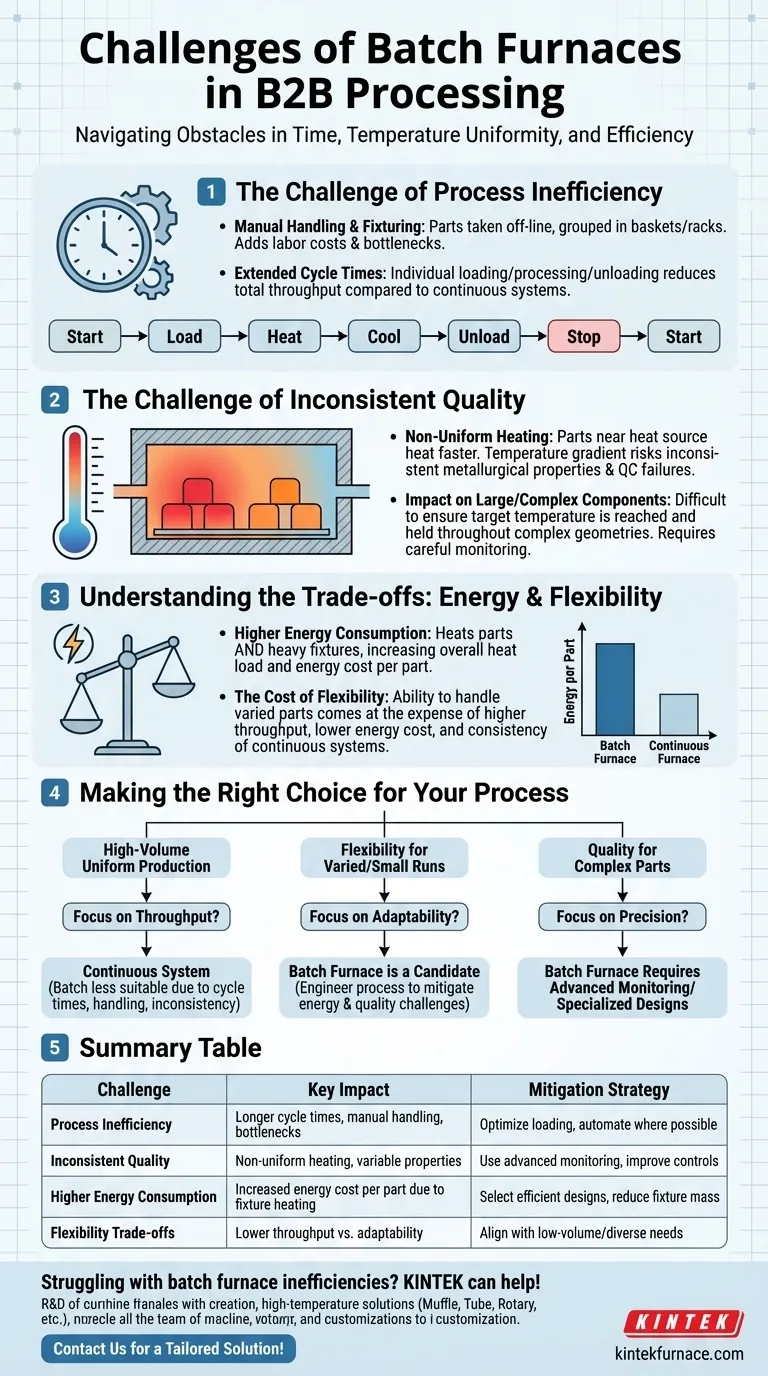

The Challenge of Process Inefficiency

Batch processing is, by definition, a start-and-stop operation. This introduces logistical and time-based inefficiencies that are not present in continuous systems.

Manual Handling and Fixturing

Parts must be taken off the main production line to be processed. They are then manually grouped and loaded into fixtures, such as specialized baskets or racks.

This manual intervention adds labor costs and creates potential bottlenecks in your workflow, interrupting what might otherwise be an automated production sequence.

Extended Cycle Times

Because each batch must be loaded, processed, and unloaded individually, the overall cycle time is often longer compared to a continuous furnace. This directly limits the total throughput of your heat-treating operation.

The Challenge of Inconsistent Quality

Achieving a perfectly uniform thermal process across an entire batch of parts is a significant technical obstacle, especially as parts become larger or more complex.

The Problem of Non-Uniform Heating

In a batch furnace, parts located closest to the heat source will inevitably heat up faster than those in the center or shadowed areas of the load.

This temperature gradient can lead to inconsistent metallurgical properties, hardness, or stress relief across the batch, potentially resulting in quality control failures.

The Impact on Large or Complex Components

This issue is magnified for large or intricately shaped parts. Ensuring that every section of a complex geometry reaches and holds the target temperature for the required duration demands extremely careful monitoring and sophisticated furnace controls.

Understanding the Trade-offs

The core benefit of a batch furnace—its flexibility—comes with direct costs in energy and operational complexity.

Higher Energy Consumption per Part

Batch furnaces must heat not only the parts but also the heavy fixtures (baskets or racks) that hold them. This added mass significantly increases the overall heat load.

This means a portion of your energy consumption is spent heating the equipment itself with every single cycle, increasing the energy cost per part produced.

The Cost of Flexibility

The key advantage of a batch furnace is its ability to handle different parts, cycle times, and temperatures from one load to the next.

However, this flexibility is traded for the higher throughput, lower energy cost, and superior process consistency often found in continuous furnaces designed for a single, high-volume product.

Making the Right Choice for Your Process

Selecting the right furnace technology requires aligning its characteristics with your primary production goals.

- If your primary focus is high-volume, uniform production: The longer cycle times, manual handling, and potential for inconsistency make a batch furnace less suitable than a continuous system.

- If your primary focus is flexibility for varied parts or small runs: A batch furnace is a strong candidate, but you must engineer your process to mitigate the challenges of energy consumption and ensure quality control.

- If your primary focus is quality for complex parts: The risk of non-uniform heating in a batch furnace requires advanced monitoring or specialized designs to ensure every part meets specification.

By clearly defining your operational priorities, you can determine whether the flexibility of a batch furnace justifies its inherent process challenges.

Summary Table:

| Challenge | Key Impact | Mitigation Strategy |

|---|---|---|

| Process Inefficiency | Longer cycle times, manual handling, bottlenecks | Optimize loading procedures, automate where possible |

| Inconsistent Quality | Non-uniform heating, variable metallurgical properties | Use advanced monitoring, improve furnace controls |

| Higher Energy Consumption | Increased energy cost per part due to fixture heating | Select efficient designs, reduce fixture mass |

| Flexibility Trade-offs | Lower throughput vs. adaptability for varied runs | Align with low-volume or diverse production needs |

Struggling with batch furnace inefficiencies? KINTEK can help! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Enhance your process efficiency and quality—contact us today for a tailored solution!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality