Heat treatment is the decisive factor that enables NC6 (1.2063) tool steel to function effectively in Single Point Incremental Forming (SPIF). specifically, subjecting the material to quenching and tempering to achieve a hardness of 58 HRC imparts the necessary wear resistance and structural integrity required for the process. Without this specific treatment, the tool would fail to withstand the mechanical stresses of forming.

Core Takeaway

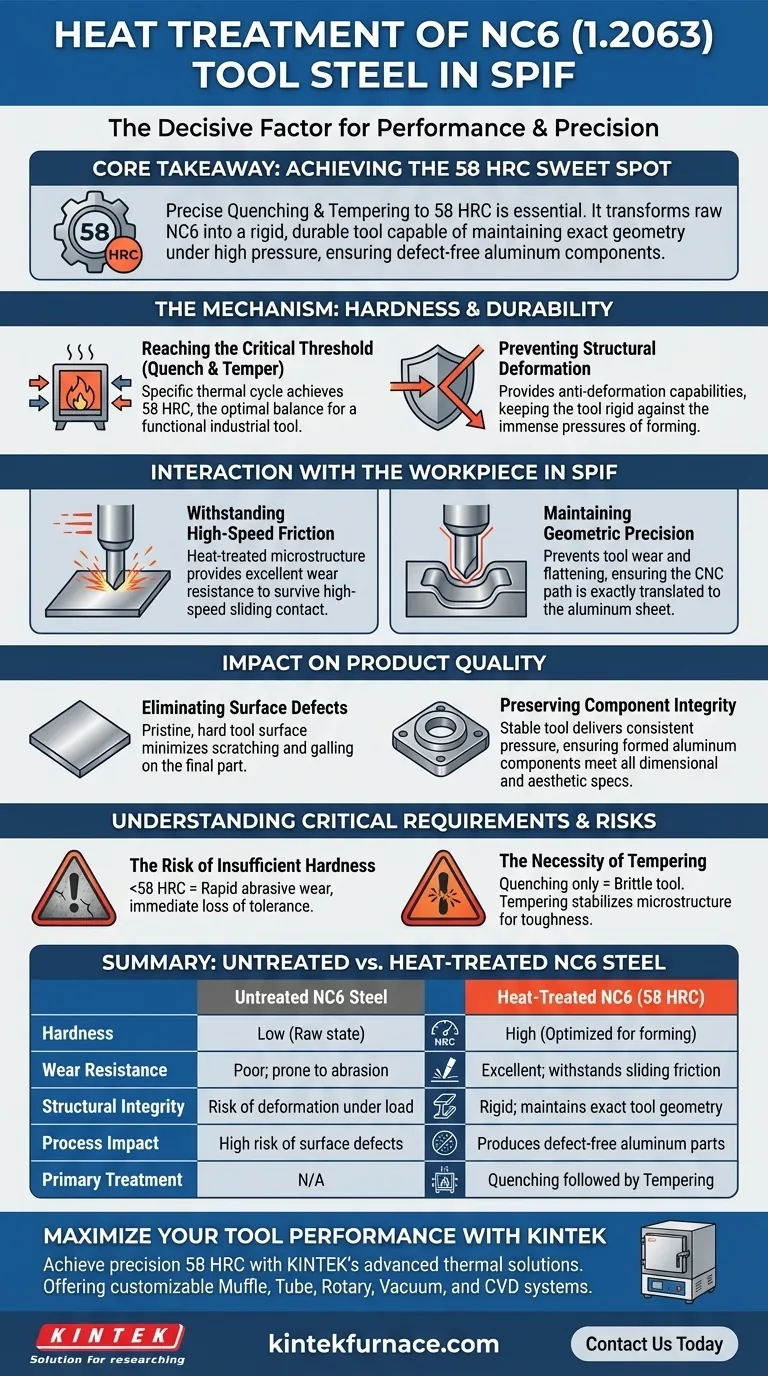

The efficacy of an NC6 forming tool relies entirely on a precise heat treatment cycle that balances hardness with durability. By targeting 58 HRC, the tool becomes rigid enough to maintain its exact geometry under high pressure, directly resulting in defect-free aluminum components.

The Mechanism of Hardness and Durability

Reaching the Critical Hardness Threshold

The raw chemical composition of NC6 steel is not enough on its own; it must undergo a specific thermal cycle.

The process requires quenching followed by tempering to reach a target hardness of 58 HRC. This specific hardness level is the sweet spot that transforms the steel from a raw material into a functional industrial tool.

Preventing Structural Deformation

In SPIF, the tool acts as a highly localized pressure point.

If the steel is too soft, the immense pressure required to deform the aluminum sheet would deform the tool itself. The 58 HRC heat treatment provides anti-deformation capabilities, ensuring the tool remains rigid regardless of the load applied.

Interaction with the Workpiece

Withstanding High-Speed Friction

The SPIF process involves the tool moving rapidly across the surface of the sheet metal.

This creates a simplified but harsh environment defined by high-speed sliding and significant friction. The heat-treated microstructure provides the wear resistance needed to survive this abrasive contact without degrading.

Maintaining Geometric Precision

The shape of the final product is dictated by the shape of the tool tip (the ball-head).

Because the heat treatment prevents the tool from wearing down or flattening out, the tool maintains its geometric precision. This ensures that the path programmed into the CNC machine is exactly translated to the aluminum sheet.

Impact on Product Quality

Eliminating Surface Defects

A degraded tool surface transfers imperfections to the workpiece.

By maintaining a pristine, hard surface through heat treatment, the tool slides smoothly over the aluminum alloy. This minimizes the generation of surface defects, such as scratching or galling, on the final part.

Preserving Component Integrity

The ultimate goal of the process is a high-quality formed part.

The heat treatment ensures the tool can deliver consistent pressure without failing. This stability preserves the overall quality of the formed aluminum components, ensuring they meet dimensional and aesthetic specifications.

Understanding the Critical Requirements

While the benefits of this treatment are clear, it is important to understand the operational risks of deviation.

The Risk of Insufficient Hardness

If the heat treatment fails to reach the 58 HRC benchmark, the tool loses its primary advantage. A softer tool will likely suffer from rapid abrasive wear, leading to immediate loss of tolerance in the final part.

The Necessity of Tempering

Quenching alone creates hardness, but often leaves the steel brittle. The inclusion of tempering in the specified process is vital. It stabilizes the microstructure, ensuring the tool is not just hard, but tough enough to handle the stress without cracking.

Making the Right Choice for Your Goal

To maximize the performance of NC6 tool steel in SPIF applications, apply the following principles:

- If your primary focus is Dimensional Accuracy: Ensure the heat treatment process is strictly controlled to achieve exactly 58 HRC to prevent tool deformation under load.

- If your primary focus is Surface Finish: Prioritize the wear resistance gained from this treatment to prevent tool degradation that causes surface defects on the aluminum.

Correctly heat-treated NC6 steel serves as the rigid foundation necessary for high-precision, defect-free incremental forming.

Summary Table:

| Feature | Untreated NC6 Steel | Heat-Treated NC6 (58 HRC) |

|---|---|---|

| Hardness | Low (Raw state) | High (Optimized for forming) |

| Wear Resistance | Poor; prone to abrasion | Excellent; withstands sliding friction |

| Structural Integrity | Risk of deformation under load | Rigid; maintains exact tool geometry |

| Process Impact | High risk of surface defects | Produces defect-free aluminum parts |

| Primary Treatment | N/A | Quenching followed by Tempering |

Maximize Your Tool Performance with KINTEK

Achieving the perfect 58 HRC for NC6 steel requires precision that only expert equipment can provide. Backed by industry-leading R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to your specific tool steel and high-temperature lab needs.

Don't let improper heat treatment compromise your product quality. Contact us today to find the ideal thermal solution for your lab and ensure your tools deliver the rigidity and precision your SPIF processes demand.

Visual Guide

References

- Łukasz Kuczek, Ryszard Sitek. Influence of Heat Treatment on Properties and Microstructure of EN AW-6082 Aluminium Alloy Drawpieces After Single-Point Incremental Sheet Forming. DOI: 10.3390/app15020783

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is the precision of a temperature control system critical in copper brazing? Ensure Perfect Joints Every Time

- Why is a forced air drying oven essential after molding biomass briquettes? Enhance Fuel Quality & Strength

- What is the primary purpose of continuously introducing high-purity argon gas? 4 Critical Roles in Solar Pyrolysis

- What are the primary technical advantages of using stainless steel for the construction of horizontal pyrolysis furnace bodies? Durability and Thermal Precision

- What is the purpose of an industrial oven for powder pre-treatment? Ensure Accurate Silica Analysis

- What is the purpose of a microwave digestion furnace? Unlock Precise ICP-MS Results through Matrix Destruction

- Why Use a Laboratory Drying Oven for Re2O7/Al2O3 Catalysts? Ensure High Dispersion & Performance

- What is the significance of using a vacuum drying oven? Optimize Supercapacitor Electrode Performance