Precision is the difference between a high-performance joint and a scrapped component. In copper brazing, you are operating within a strictly limited thermal range. A precise temperature control system is critical because it ensures the heat is high enough to melt the filler metal for proper flow, yet strictly low enough to prevent the base metal from melting or deforming.

Precision temperature control navigates the narrow operating window required for copper brazing. It maintains the delicate balance between liquefying the filler and preserving the structural integrity of the base metal, ensuring the final joint possesses the necessary mechanical strength and conductivity.

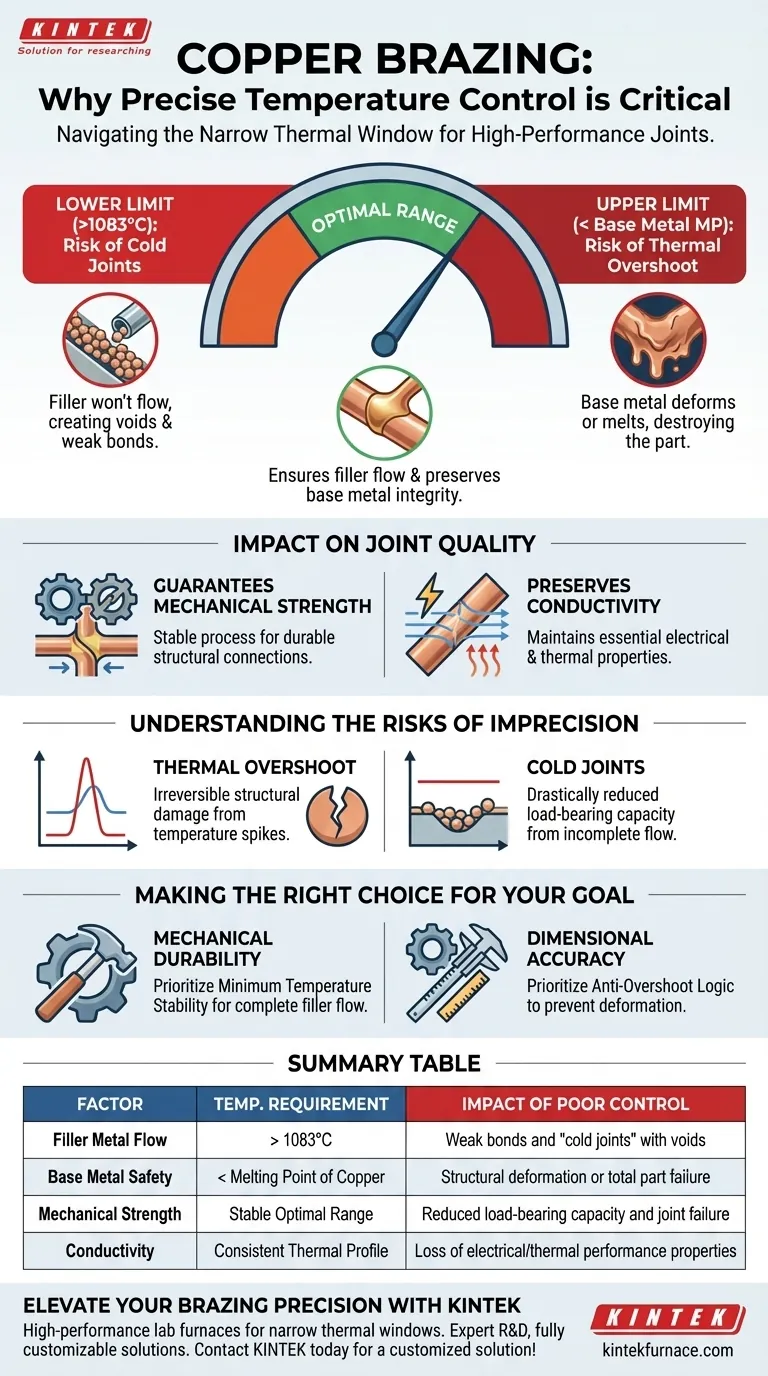

Navigating the Narrow Operating Window

The Lower Limit: Ensuring Proper Flow

To create a successful braze, the system must reach a specific thermal threshold.

According to standard process requirements, the temperature must typically exceed 1083°C to melt the filler metal. If the control system allows the temperature to dip below this point, the filler will not flow correctly, resulting in a weak or incomplete bond.

The Upper Limit: Preventing Material Failure

While high heat is necessary, there is a hard ceiling that cannot be breached.

The temperature must remain strictly below the melting point of the base metal. If an imprecise control system allows the temperature to overshoot this limit, the base copper will suffer deformation or even melt completely, destroying the part.

The Impact on Joint Quality

Guarantees Mechanical Strength

The primary goal of brazing is a durable structural connection.

An accurate control system stabilizes the process within the optimal range. This consistency is required to form a bond that meets mechanical strength specifications, preventing failure under stress.

Preserves Conductivity

Copper is frequently selected for its electrical and thermal properties.

Precision heating ensures these properties are not compromised during the joining process. Proper temperature management guarantees the electrical or thermal conductivity of the resulting joint remains intact.

Understanding the Risks of Imprecision

The Danger of Thermal Overshoot

In systems with poor control logic, "overshoot" is a common failure mode.

If the system reacts too slowly to rising heat, the temperature may momentarily spike above the safe window. Even a brief excursion above the base metal's melting point can cause irreversible structural damage.

The Risk of Cold Joints

Conversely, inconsistent heating leads to "cold joints."

If the system fluctuates and fails to maintain the minimum required temperature (above 1083°C), the filler metal may bead up rather than flow. This creates voids in the joint, drastically reducing its load-bearing capacity.

Making the Right Choice for Your Goal

To apply this to your production environment, assess your priorities based on the component's end-use:

- If your primary focus is mechanical durability: Ensure your control system prioritizes minimum temperature stability to guarantee complete filler flow and bond penetration.

- If your primary focus is dimensional accuracy: Prioritize a control system with anti-overshoot logic to ensure the base metal never approaches its deformation point.

The quality of your temperature control system is the single most important factor in securing the reliability of your copper brazed assemblies.

Summary Table:

| Key Factor | Temperature Requirement | Impact of Poor Control |

|---|---|---|

| Filler Metal Flow | > 1083°C | Weak bonds and "cold joints" with voids |

| Base Metal Safety | < Melting Point of Copper | Structural deformation or total part failure |

| Mechanical Strength | Stable Optimal Range | Reduced load-bearing capacity and joint failure |

| Conductivity | Consistent Thermal Profile | Loss of electrical/thermal performance properties |

Elevate Your Brazing Precision with KINTEK

Don’t let thermal overshoot or inconsistent heating compromise your production quality. KINTEK provides high-performance lab high-temp furnaces, including vacuum and tube systems, specifically designed to handle the narrow thermal windows required for copper brazing.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique metallurgical needs. Ensure the mechanical strength and conductivity of your assemblies—Contact KINTEK today for a customized solution!

Visual Guide

References

- Er. RoshanY. Gonnade. Copper Brazing Technology. DOI: 10.22214/ijraset.2025.73740

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do microprocessor-controlled electric furnaces ensure the homogeneity of the Se80In5Te6Sb9 alloy?

- What is an industrial oven and which industries use it? Discover Versatile Thermal Processing Solutions

- What is the purpose of setting an industrial drying oven to 70°C for sludge? Preserve Volatiles & Optimize Pre-treatment

- Why specific constant temperature holding times for NbC and Cr7C3? Achieve Stoichiometric Precision in Lab Synthesis

- What are the objectives of melt stirring and insulation treatment during the Al-5Er-Ti master alloy preparation process?

- Why is a constant temperature drying oven used for activated carbon? Ensure Pore Integrity and Adsorption Efficiency

- How does the combination of a nitrogen atmosphere and magnetic stirring benefit the dissolution stage? | KINTEK

- What is the function of a vacuum drying oven in SFRP processing? Preserve Material Integrity & Prevent Degradation