Stainless steel is the premier material choice for constructing horizontal pyrolysis furnace bodies primarily because of its exceptional high-temperature strength and resistance to oxidation. It ensures the equipment maintains structural stability without deformation during prolonged heating cycles, while also minimizing heat loss to create a uniform thermal environment within the reactor.

The core value of stainless steel lies in its ability to combine mechanical robustness with thermal efficiency; it prevents structural warping and maintains a stable temperature field, which is critical for consistent pyrolysis results and extended equipment life.

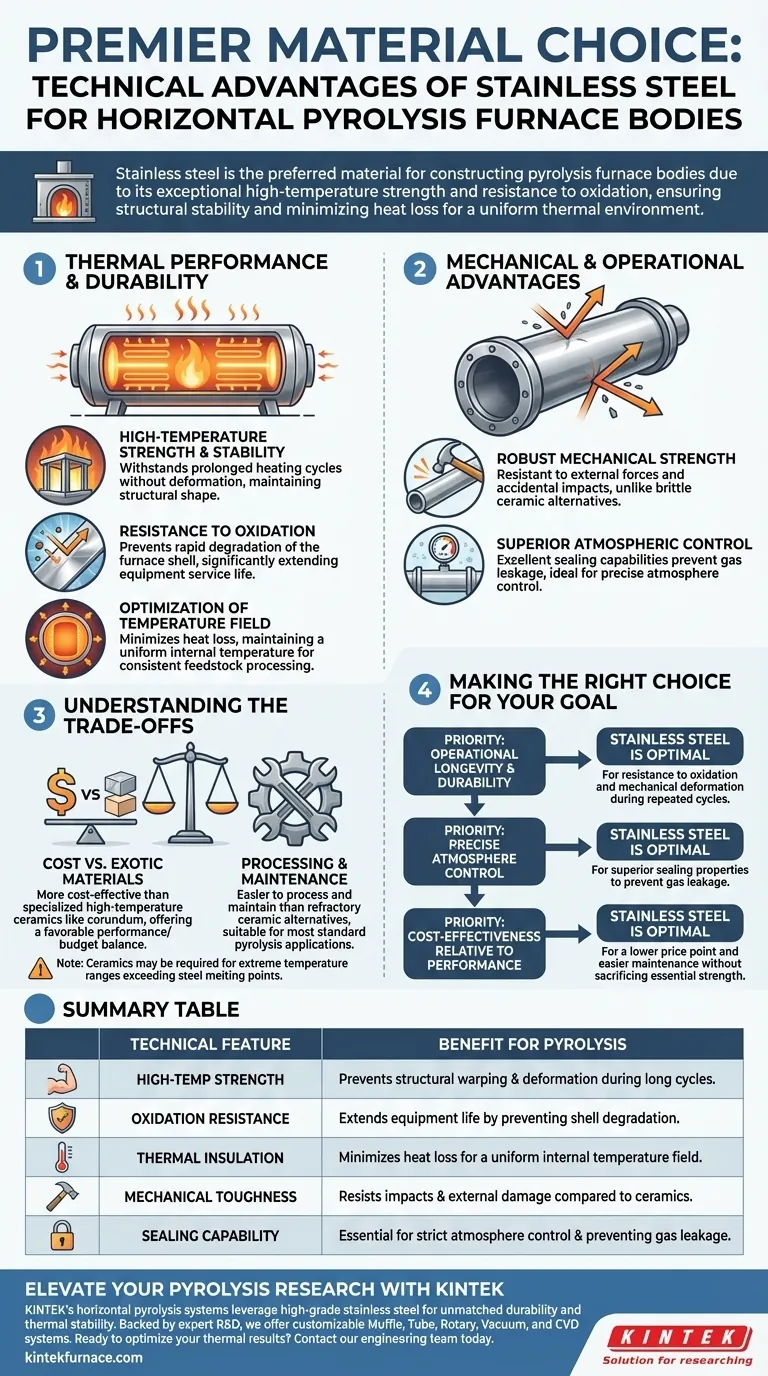

Thermal Performance and Durability

High-Temperature Strength and Stability

The most critical requirement for a pyrolysis furnace is the ability to withstand intense heat without failing. Stainless steel provides excellent high-temperature strength, allowing the furnace body to endure prolonged heating cycles. Unlike lesser materials, it maintains its shape and does not deform under the thermal stress of continuous operation.

Resistance to Oxidation

Pyrolysis involves high heat, which accelerates corrosion and degradation in many metals. Stainless steel offers superior oxidation resistance, preventing the furnace shell from degrading rapidly. This resistance is a key factor in significantly extending the overall service life of the equipment.

Optimization of the Temperature Field

Achieving consistent chemical reactions requires precise temperature control. Stainless steel effectively minimizes heat loss from the furnace body. This insulation effect helps maintain a uniform temperature field inside the pyrolysis reactor, ensuring that the feedstock is processed evenly.

Mechanical and Operational Advantages

Robust Mechanical Strength

Beyond thermal properties, the physical toughness of the material matters in an industrial or lab setting. Stainless steel tubes possess high mechanical strength, making them resistant to external forces and accidental impacts. Unlike brittle ceramic alternatives, stainless steel is not easily damaged during handling or processing.

Superior Atmospheric Control

Many pyrolysis experiments require a specific, controlled atmosphere to prevent unwanted reactions. Stainless steel provides excellent sealing capabilities, effectively preventing gas leakage. This makes it ideal for processes that demand strict atmosphere control and precision.

Understanding the Trade-offs

Cost vs. Exotic Materials

While stainless steel is a premium material, it is often more cost-effective than specialized high-temperature ceramics. Compared to materials like corundum (aluminum oxide), stainless steel has a relatively lower price point. It offers a favorable balance of performance and budget for most standard pyrolysis applications.

Processing and Maintenance

Ease of use is a significant logistical advantage. Stainless steel is generally easier to process and maintain than refractory ceramic alternatives. However, it is important to note that for extreme temperature ranges that exceed the melting point of steel alloys, ceramic options may still be required despite their higher cost and brittleness.

Making the Right Choice for Your Goal

To determine if a stainless steel furnace body aligns with your specific project requirements, consider the following priorities:

- If your primary focus is operational longevity and durability: Stainless steel is the optimal choice due to its resistance to oxidation and mechanical deformation during repeated heating cycles.

- If your primary focus is precise atmosphere control: The superior sealing properties of stainless steel make it the best option for experiments requiring strict prevention of gas leakage.

- If your primary focus is cost-effectiveness relative to performance: Stainless steel offers a lower price point and easier maintenance than exotic materials like corundum, without sacrificing essential mechanical strength.

Select stainless steel when you need a reliable, robust solution that balances thermal precision with mechanical toughness.

Summary Table:

| Technical Feature | Benefit for Pyrolysis |

|---|---|

| High-Temp Strength | Prevents structural warping and deformation during long cycles |

| Oxidation Resistance | Extends equipment life by preventing shell degradation |

| Thermal Insulation | Minimizes heat loss to ensure a uniform internal temperature field |

| Mechanical Toughness | Resists impacts and external damage compared to brittle ceramics |

| Sealing Capability | Essential for strict atmosphere control and preventing gas leakage |

Elevate Your Pyrolysis Research with KINTEK

Don’t compromise on the structural integrity of your thermal processes. KINTEK’s horizontal pyrolysis systems leverage high-grade stainless steel and advanced engineering to provide unmatched durability and thermal stability.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temperature furnaces are fully customizable to meet your unique research or industrial requirements.

Ready to optimize your thermal results? Contact our engineering team today to discuss how our robust furnace designs can enhance your lab's efficiency and precision.

Visual Guide

References

- Hitesh Panchal. Fuel Extraction from Plastic Waste. DOI: 10.22214/ijraset.2025.66489

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-precision temperature control system contribute to NMC synthesis? Precision in XRD In-Situ Experiments

- What are the advantages of the Laser Hearth Method for Zirconia? Achieve High Purity & Density for Advanced Research

- What are the process advantages of using a vacuum oven for drying adsorbent precursors? Ensure Chemical Uniformity

- Why Use a Laboratory Drying Oven for Re2O7/Al2O3 Catalysts? Ensure High Dispersion & Performance

- What effect does water-quench cooling equipment have on the microstructure of Invar 36? Expert Analysis

- Why Use a Precision Heating Oil Bath for AP-SCVD? Master Precursor Vapor Pressure for Thin Film Accuracy

- What is the technical objective of performing thermal oxidation at 625 °C? Mastering SiOx Tunnel Oxide Precision

- What role does a nitrogen protection device play in copper-based halide thin films? Optimize Your Lab Annealing Process