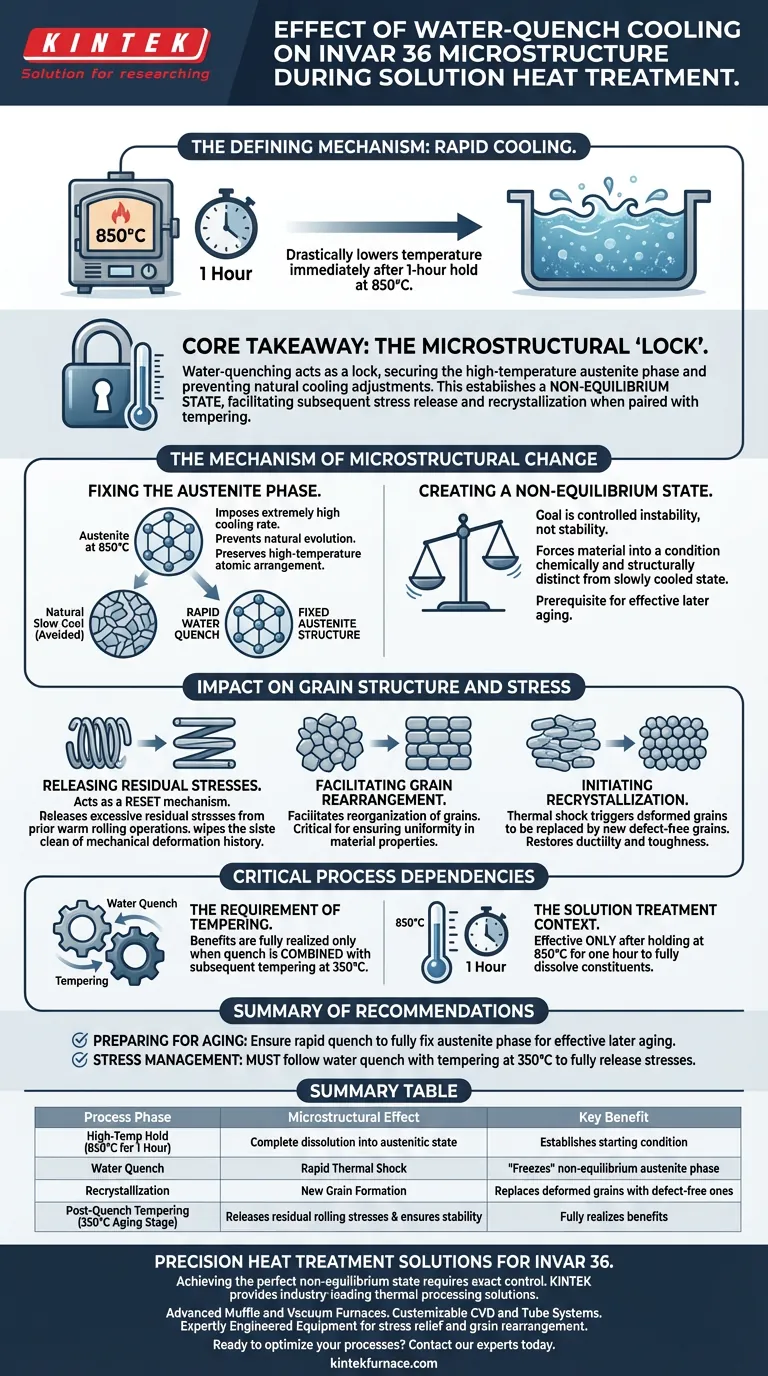

Rapid cooling is the defining mechanism. Water-quench cooling equipment is employed to drastically lower the temperature of Invar 36 immediately after it has been held at a solution temperature of 850 °C for one hour. The primary effect of this high cooling rate is to "freeze" or fix the austenite microstructure in its high-temperature state, creating a specific non-equilibrium condition required for subsequent processing.

Core Takeaway Water-quenching acts as a microstructural "lock," securing the high-temperature austenite phase to prevent natural cooling adjustments. By establishing a non-equilibrium state, this process—when paired with tempering—facilitates the release of rolling stresses and initiates the critical recrystallization of the alloy's grain structure.

The Mechanism of Microstructural Change

Fixing the Austenite Phase

The equipment’s function is to impose an extremely high cooling rate on the alloy. At 850 °C, Invar 36 exists in an austenitic state.

By cooling the material rapidly with water, you prevent the microstructure from evolving as it naturally would during a slow cool. This effectively fixes the austenite structure, preserving the atomic arrangement found at high temperatures.

Creating a Non-Equilibrium State

The goal of this process is not stability, but rather controlled instability.

Water quenching forces the material into a non-equilibrium condition. This state is chemically and structurally distinct from the state the material would achieve if allowed to cool slowly to room temperature. This specific condition is a prerequisite for the effectiveness of later aging stages.

Impact on Grain Structure and Stress

Releasing Residual Stresses

While quenching is often associated with inducing stress in other materials, its role here acts as a reset mechanism.

Invar 36 often contains excessive residual stresses from prior warm rolling operations. The solution heat treatment, capped by this water quench, helps release these residual stresses. It essentially wipes the slate clean of previous mechanical deformation history.

Facilitating Grain Rearrangement

Beyond stress relief, the quench plays a vital role in the evolution of the grains themselves.

The process facilitates grain rearrangement within the microstructure. This reorganization is critical for ensuring uniformity in the material's properties.

Initiating Recrystallization

The thermal shock and subsequent state of the material trigger the beginning of recrystallization.

This is the process where deformed grains are replaced by a new set of defect-free grains. This structural renewal is essential for restoring the ductility and toughness of the Invar 36.

Critical Process Dependencies

The Requirement of Tempering

It is critical to note that water quenching is part of a dual-step system.

The benefits described—specifically the release of stress and grain rearrangement—are fully realized when the quench is combined with subsequent tempering at 350 °C.

The Solution Treatment Context

The quench cannot be viewed in isolation from the heating cycle.

It is specifically effective only after the material has been held at 850 °C for one hour. If the material is not held at this temperature long enough to fully dissolve constituents into the austenite, the water quench will not produce the correct non-equilibrium structure.

Applying This to Your Process

Summary of Recommendations

- If your primary focus is Preparing for Aging: Ensure the quench is rapid enough to fully fix the austenite phase, as this non-equilibrium state is necessary for effective aging later.

- If your primary focus is Stress Management: Do not rely on quenching alone; you must follow the water quench with tempering at 350 °C to fully release excessive stresses from warm rolling.

Success in treating Invar 36 relies on using the water quench not as a final step, but as a precise method to lock in the microstructure required for effective tempering.

Summary Table:

| Process Phase | Microstructural Effect | Key Benefit |

|---|---|---|

| High-Temp Hold | 850 °C for 1 Hour | Complete dissolution into austenitic state |

| Water Quench | Rapid Thermal Shock | "Freezes" non-equilibrium austenite phase |

| Recrystallization | New Grain Formation | Replaces deformed grains with defect-free ones |

| Post-Quench Tempering | 350 °C Aging Stage | Releases residual rolling stresses & ensures stability |

Precision Heat Treatment Solutions for Invar 36

Achieving the perfect non-equilibrium state in Invar 36 requires exact temperature control and reliable quenching mechanisms. KINTEK provides industry-leading thermal processing solutions designed to meet the rigorous demands of material science.

Backed by expert R&D and manufacturing, we offer:

- Advanced Muffle and Vacuum Furnaces for precise solution treatment.

- Customizable CVD and Tube Systems tailored to your specific alloy requirements.

- Expertly Engineered Equipment to facilitate stress relief and grain rearrangement.

Ready to optimize your lab's high-temperature processes? Contact our experts today to discover how KINTEK’s customizable lab furnaces can enhance your material performance.

Visual Guide

References

- Mehmet Kul, Markus Merkel. Minimum and Stable Coefficient of Thermal Expansion by Three-Step Heat Treatment of Invar 36. DOI: 10.3390/cryst14121097

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the core function of a drying furnace in mold preparation? Build High-Strength Inorganic Silicate Molds

- What processing conditions does an industrial heating furnace provide during hot forging? Optimize Fe-Mn-Si Alloys

- What is the role of a controlled hot-air circulation oven in determining the chemical composition of dried yoghurt?

- How does a high-precision laboratory oven ensure the performance of large-scale halide perovskite catalyst plates?

- Why are high-precision nitrogen flow meters essential during pyrolysis? Ensure Perfect Char Preparation

- What is the use of furnace in laboratory? Unlock Precise High-Temperature Control for Material Transformations

- Why is high-purity argon necessary for PVC dechlorination? Ensure Precise Reaction Control & Safety

- Why is precise temperature control programming indispensable for SFC research? Optimize Sintering Process Success