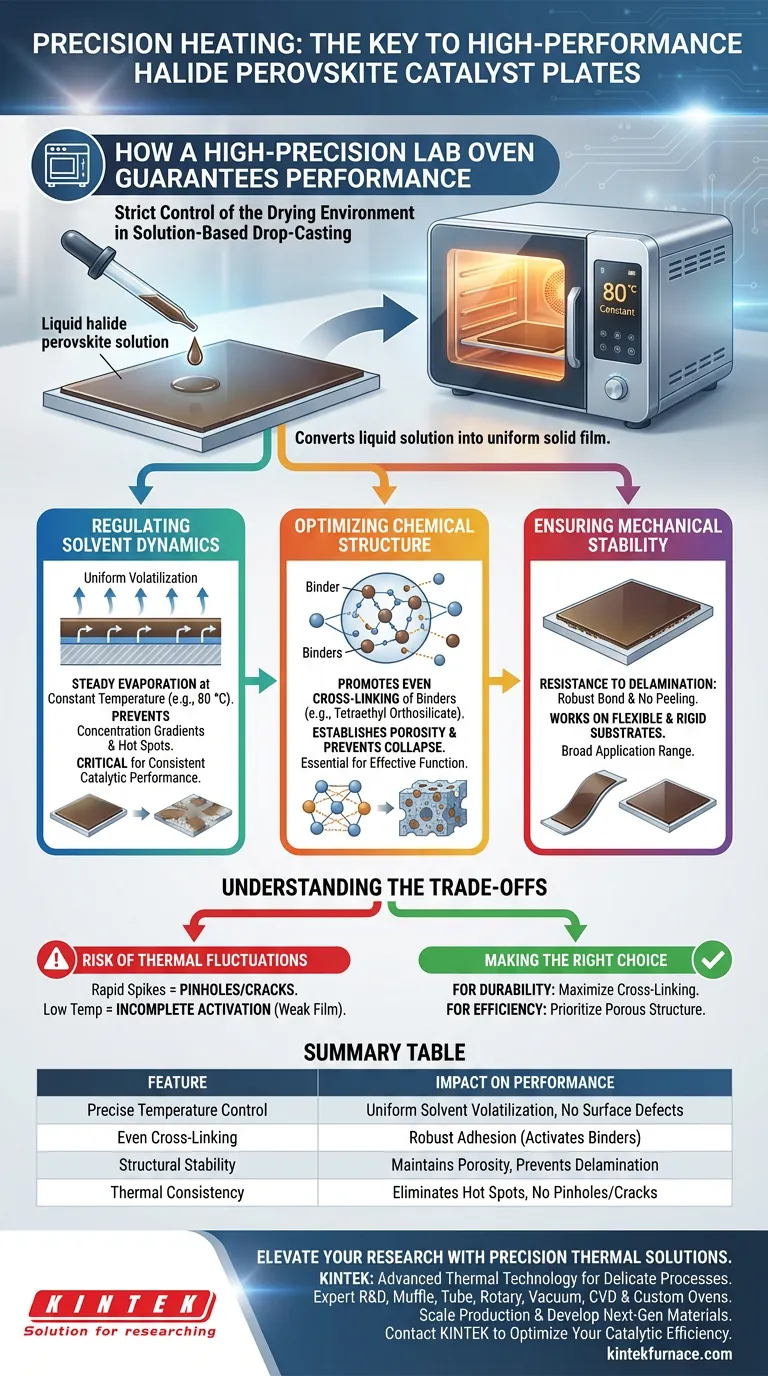

A high-precision laboratory oven guarantees the performance of large-scale halide perovskite catalyst plates by strictly controlling the drying environment. By maintaining a constant evaporation temperature, such as 80 °C, the oven ensures that solvents volatilize uniformly rather than erratically. This precise thermal regulation promotes the even cross-linking of binders, resulting in a porous, structurally stable coating that adheres firmly to the substrate.

The critical challenge in scaling halide perovskite catalysts is converting a liquid solution into a uniform solid film without defects. High-precision thermal regulation is the key variable that locks in structural integrity and prevents the coating failures common in drop-casting.

Regulating Solvent Dynamics

Uniform Volatilization

In solution-based drop-casting, the rate at which the solvent leaves the material dictates the final film quality. A high-precision oven maintains a static temperature (e.g., 80 °C) to ensure the solvent evaporates steadily.

Preventing Concentration Gradients

By guiding uniform volatilization, the oven prevents the formation of "hot spots" or uneven drying zones. This ensures the dissolved materials do not aggregate unevenly, which is essential for maintaining consistent catalytic performance across large-scale plates.

Optimizing the Chemical Structure

Promoting Even Cross-Linking

Heat is not just for drying; it activates the chemical binders that hold the catalyst together. The controlled environment allows binders, such as tetraethyl orthosilicate, to cross-link evenly throughout the material.

Establishing Porosity

A specific porous structure is required for the catalyst to function effectively. The controlled heating process locks in this porosity during the transition from liquid to solid, preventing the collapse of the material's internal architecture.

Ensuring Mechanical Stability

Resistance to Delamination

A common failure point in coating technologies is delamination, where the material peels away from the base. The uniform cross-linking achieved through precision heating creates a robust bond, making the coating highly resistant to delamination.

Substrate Versatility

This thermal process is effective for various base materials. It produces structurally stable coatings on both flexible and rigid substrates, allowing for broader application of the catalyst plates.

Understanding the Trade-offs

The Risk of Thermal Fluctuations

If the oven lacks high precision, even minor temperature fluctuations can be detrimental. Rapid heating spikes can cause solvents to boil rather than evaporate, leading to pinholes or cracks in the surface.

Incomplete Binder Activation

Conversely, if the temperature drops below the target setpoint, the binder (like tetraethyl orthosilicate) may not cross-link fully. This results in a weak, powdery film that lacks the mechanical strength to survive operational conditions.

Making the Right Choice for Your Goal

To maximize the efficacy of your halide perovskite catalyst plates, align your thermal processing with your specific performance metrics:

- If your primary focus is Durability: Ensure the oven maintains strict consistency at the binder's activation temperature to maximize cross-linking and prevent delamination.

- If your primary focus is Catalytic Efficiency: Prioritize precise evaporation rates to maintain the optimal porous structure required for surface reactions.

Precision heating transforms a volatile chemical solution into a durable, high-performance catalytic tool.

Summary Table:

| Feature | Impact on Catalyst Plate Performance |

|---|---|

| Precise Temperature Control | Ensures uniform solvent volatilization and prevents surface defects. |

| Even Cross-Linking | Activates binders like tetraethyl orthosilicate for robust substrate adhesion. |

| Structural Stability | Maintains essential porosity and prevents material delamination. |

| Thermal Consistency | Eliminates hot spots and prevents the formation of pinholes or cracks. |

Elevate Your Research with Precision Thermal Solutions

Precision heating is the difference between a failed coating and a high-performance catalytic tool. KINTEK provides the advanced thermal technology required for the most delicate solution-based processes.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable laboratory ovens designed for unique research needs. Whether you are scaling halide perovskite production or developing next-generation materials, our systems ensure the structural integrity and durability your projects demand.

Ready to optimize your catalytic efficiency? Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- Hui Fu, Peng Wang. A scalable solar-driven photocatalytic system for separated H2 and O2 production from water. DOI: 10.1038/s41467-025-56314-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What is the primary purpose of using a laboratory constant temperature drying oven for fuel sample preparation?

- Why is a high-pressure digestion tank essential for ZnO/rGO hydrothermal synthesis? Achieve superior interfacial coupling

- What is the technical necessity of using a laboratory vacuum drying oven for Cu-Fe-N-C catalyst precursors?

- What is the primary role of high-purity hydrogen in heat treatment? Achieve Superior Metallic Coating Protection

- How do the rotational and orbital movements of the sample stage contribute to the uniformity of coatings on Zircaloy?

- How does a constant temperature and humidity curing chamber contribute to GCCM hydration? Optimize Material Strength

- How does a temperature-controlled heating chamber ensure AEMWE testing accuracy? Unlock Reliable Electrolyzer Data

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?