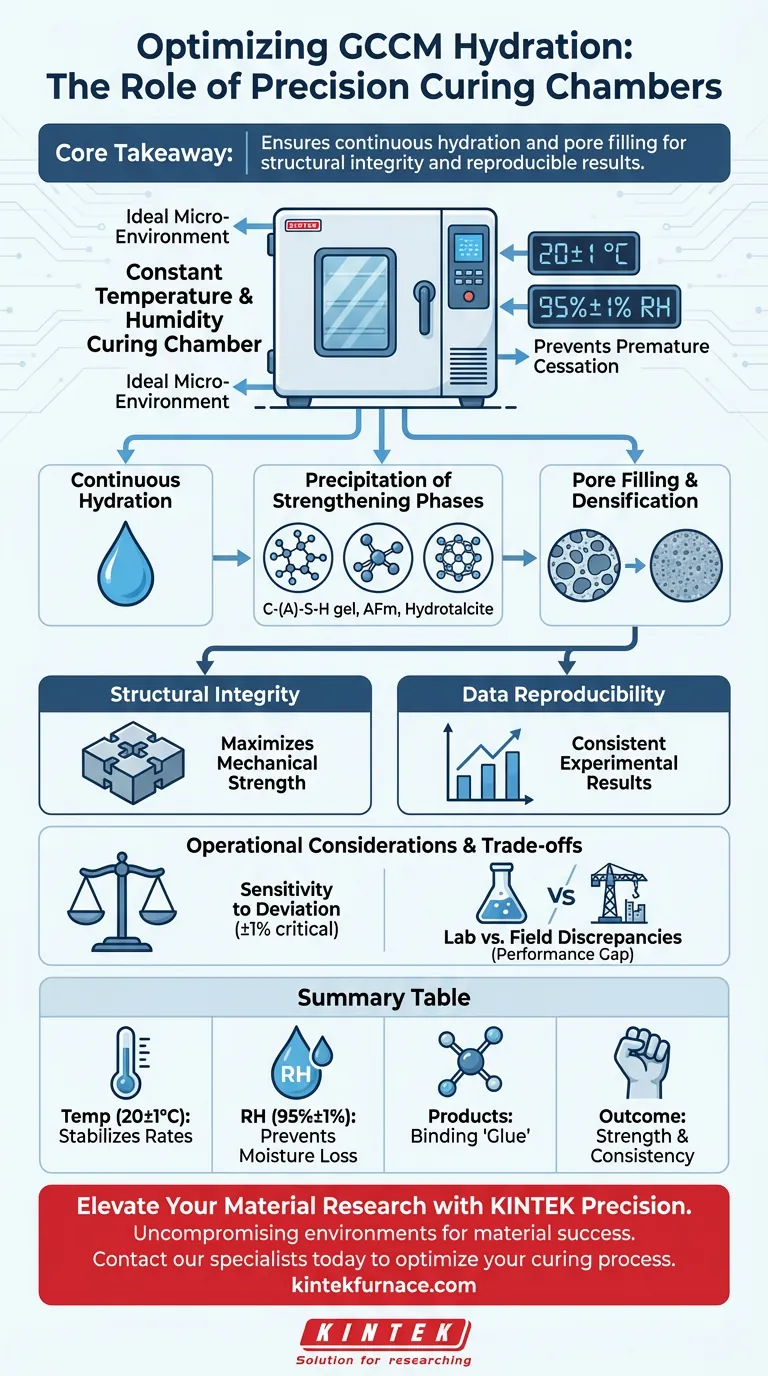

A constant temperature and humidity curing chamber serves as a critical stabilization tool for the chemical evolution of Geopolymer Cementitious Materials (GCCM). By maintaining a rigorous micro-environment—specifically 20±1 °C and 95%±1% relative humidity—it prevents the premature cessation of hydration. This controlled atmosphere allows for the continuous, uninterrupted precipitation of binding phases necessary for physical strength.

Core Takeaway The curing chamber ensures the gradual and complete formation of strengthening phases like C-(A)-S-H gel and hydrotalcite by preventing moisture loss. This process is essential for filling micropores to achieve structural integrity and guarantees that experimental data remains reproducible across different batches.

The Role of Environmental Stability

Maintaining the Ideal Micro-Environment

For GCCM to develop properly, it requires a setting that mimics ideal curing conditions without fluctuation. The chamber provides this by locking in a temperature of 20±1 °C and a relative humidity of 95%±1%.

This precision eliminates external variables that could disrupt the chemical reactions. Without this stability, the material risks drying out or reacting unevenly, compromising its final properties.

Ensuring Continuous Hydration

The primary function of this high-humidity environment is to drive the continuous progression of the hydration reaction.

If the moisture content drops, the reaction stalls, leaving unreacted particles. The chamber ensures that water remains available as a reactant and transport medium throughout the curing process.

Formation of Specific Hydration Products

Precipitation of Strengthening Phases

Under these stable conditions, specific chemical products are able to precipitate gradually. The primary reference highlights the formation of C-(A)-S-H gel, AFm, and hydrotalcite.

These phases are the "glues" of the geopolymer system. Their proper formation is directly linked to the mechanical strength of the final material.

The Mechanism of Pore Filling

As these hydration products form, they occupy space within the material's microstructure. The controlled environment allows these phases to effectively fill micropores.

This densification reduces porosity. A denser microstructure leads to higher durability and better resistance to environmental stressors.

Importance for Research and Engineering

Reproducibility of Data

For scientific analysis, consistency is paramount. The curing chamber ensures that every sample is subjected to the exact same history of temperature and moisture.

This guarantees the reproducibility of experimental data. Researchers can be confident that variations in strength are due to material formulation, not erratic curing conditions.

Structural Integrity

Ultimately, the goal of GCCM is to bear loads. The chamber facilitates the full development of the material's internal structure.

By maximizing hydration and pore filling, the chamber ensures the structural integrity of the cementitious material is achieved as designed.

Operational Considerations and Trade-offs

Sensitivity to Deviation

While these chambers are precise, the material is highly sensitive to even minor deviations. A failure to maintain the ±1% tolerance in humidity or temperature can alter the rate of crystal growth, leading to inconsistent microstructures.

Lab vs. Field Discrepancies

It is important to acknowledge that this "ideal" curing environment represents a best-case scenario.

Materials cured in this perfect micro-environment may exhibit superior properties compared to those cured in uncontrolled field conditions. Engineers must account for this performance gap when translating lab results to real-world applications.

Making the Right Choice for Your Goal

To maximize the utility of your curing chamber for GCCM, consider your specific objectives:

- If your primary focus is Research Accuracy: Ensure strict adherence to the ±1% tolerances to guarantee that any observed changes in strength are solely due to your mix design, not environmental variance.

- If your primary focus is Material Strength: prioritize maintaining 95% relative humidity to prevent self-desiccation and ensure maximum pore filling by the C-(A)-S-H gels.

By strictly controlling the curing environment, you transition GCCM from a theoretical mixture into a reliable, high-performance structural material.

Summary Table:

| Parameter | Standard Requirement | Impact on GCCM Hydration |

|---|---|---|

| Temperature | 20±1 °C | Stabilizes chemical reaction rates and crystal growth. |

| Relative Humidity | 95%±1% | Prevents moisture loss; ensures continuous C-(A)-S-H gel precipitation. |

| Key Products | C-(A)-S-H, AFm, Hydrotalcite | Acts as binding 'glue' to fill micropores and increase density. |

| Outcome | Structural Integrity | Maximizes mechanical strength and ensures data reproducibility. |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect chemical evolution in Geopolymer Cementitious Materials (GCCM) requires more than just a formula—it requires an uncompromising environment. KINTEK provides industry-leading constant temperature and humidity chambers designed to maintain the rigorous ±1% tolerances essential for continuous hydration and pore-filling.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique material science needs. Ensure your experimental data is reproducible and your structural materials reach their peak performance.

Ready to optimize your curing process? Contact our laboratory specialists today to find the perfect high-temp or environmental system for your application.

Visual Guide

References

- Jianmin Li, Kai Wang. Study on the synergistic hydration mechanism of granulated blast furnace slag-carbide slag-based cementitious materials and the properties of full-solid waste backfill materials. DOI: 10.1038/s41598-025-86509-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Ultra High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass for KF

People Also Ask

- What role does a releasing agent play during the assembly process of titanium-steel composite plates?

- What are the advantages of using microwave drying equipment for organic gels? Preserve Pore Structures Effectively

- What problem does a fluidized bed address in ceramic molds? Ensure Uniform Shells for High-Temp Casting

- Why is precise temperature control essential for carbon material synthesis? Achieve Superior Purity and Microstructure

- What is the importance of providing technical documentation for high-temperature furnaces in multiple languages?

- What are the core technical advantages of using SPS for Titanium Diboride ceramics? Achieve High Density & Fine Grains

- What conditions are required for grafting norbornene functional groups onto S-glass fiber surfaces? Expert Protocol

- Why is it essential to maintain an environment between 80 and 120°C? Optimize Your Plastic Deformation Processing