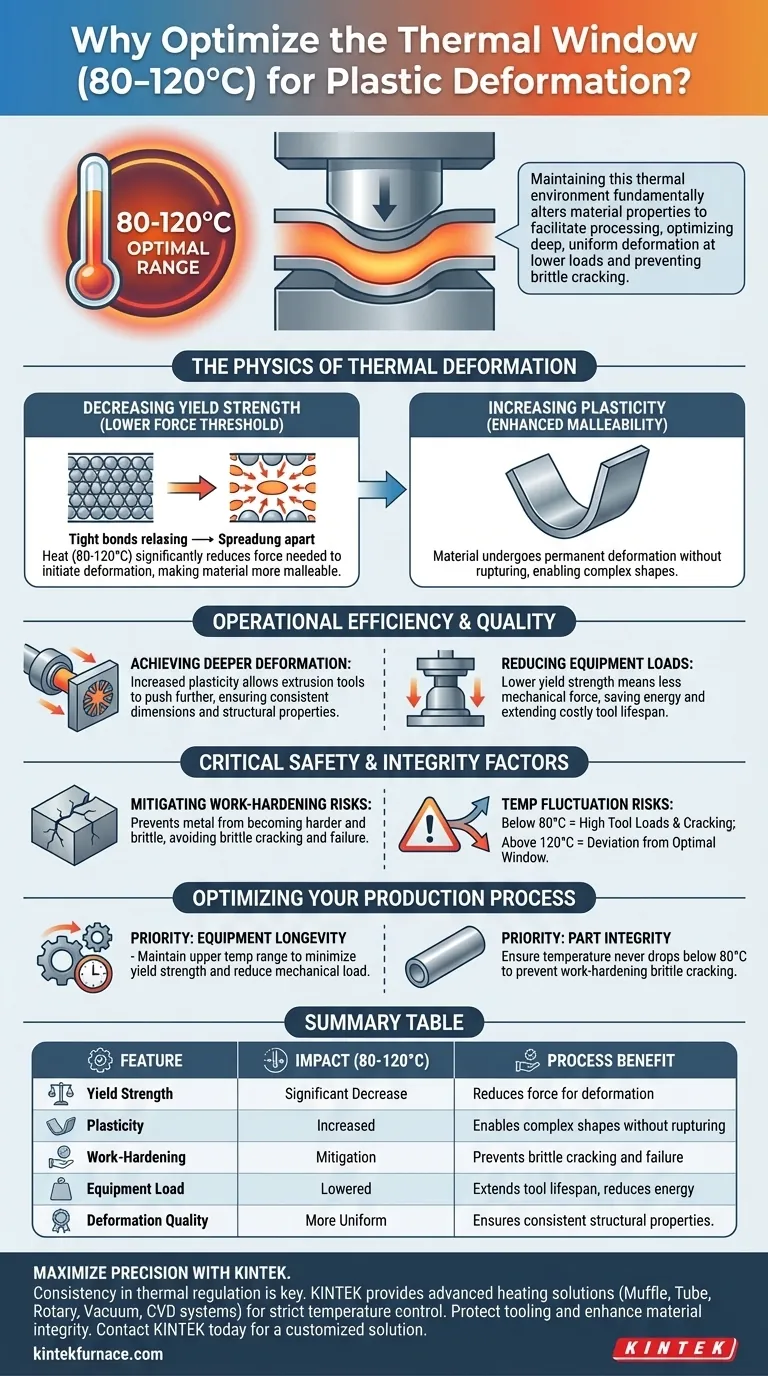

Maintaining a thermal environment between 80 and 120°C is essential during plastic deformation because it fundamentally alters the material's physical properties to facilitate processing. Keeping the material within this specific temperature window decreases its yield strength while simultaneously increasing its plasticity.

Precise temperature control in this range optimizes the manufacturing process by enabling deeper, more uniform deformation at lower equipment loads, while critically preventing brittle cracking associated with work-hardening.

The Physics of Thermal Deformation

Decreasing Yield Strength

At ambient temperatures, metals often require significant force to permanently change shape.

Heating the environment to between 80 and 120°C lowers the material's yield strength. This means the threshold of force required to initiate plastic deformation is significantly reduced, making the material more malleable.

Increasing Plasticity

As yield strength drops, plasticity—the ability of the material to undergo permanent deformation without rupturing—increases.

This thermal state allows the internal structure of the metal to flow more freely. It enables the creation of complex shapes that would be impossible or risky to attempt at lower temperatures.

Operational Efficiency and Quality

Achieving Deeper Deformation

With increased plasticity, extrusion tools can push the material further than cold processing would allow.

You can achieve deeper and more uniform plastic deformation. This ensures the final product has consistent dimensions and structural properties throughout its geometry.

Reducing Equipment Loads

Because the material yields more easily in this temperature range, the mechanical load on extrusion tools is lowered.

This reduction in force not only saves energy but also reduces wear and tear on expensive tooling, potentially extending the lifespan of your equipment.

Critical Safety and Integrity Factors

Mitigating Work-Hardening Risks

A common pitfall in plastic deformation is work-hardening, where the metal becomes harder and more brittle as it is deformed.

If not managed, this leads to brittle cracking, causing the part to fail during or after production. Maintaining the temperature between 80 and 120°C counteracts this effect, keeping the material ductile enough to survive the process without fracturing.

The Consequence of Temperature Fluctuation

It is vital to note that falling outside this specific range compromises the process.

Below 80°C, the material may remain too stiff, leading to high tool loads and cracking. Exceeding 120°C (though not explicitly detailed in the reference as a failure mode) would deviate from the optimal window for the specific balance of strength and plasticity described.

Optimizing Your Production Process

To ensure consistent quality and tool longevity, you must prioritize strict thermal regulation.

- If your primary focus is Equipment Longevity: Maintain the upper end of the acceptable temperature range to minimize yield strength and reduce the mechanical load on your extrusion tools.

- If your primary focus is Part Integrity: Ensure the environment never drops below 80°C to prevent brittle cracking during the work-hardening phase.

Control your thermal environment precisely to achieve deep, uniform deformation without compromising the structural integrity of your material.

Summary Table:

| Feature | Impact of 80-120°C Range | Process Benefit |

|---|---|---|

| Yield Strength | Significant Decrease | Reduces force required for deformation |

| Plasticity | Increased | Enables complex shapes without rupturing |

| Work-Hardening | Mitigation | Prevents brittle cracking and material failure |

| Equipment Load | Lowered | Extends tool lifespan and reduces energy use |

| Deformation Quality | More Uniform | Ensures consistent structural properties |

Maximize Precision in Plastic Deformation

Consistency in thermal regulation is the difference between a high-quality component and a brittle failure. KINTEK provides the advanced heating solutions necessary to maintain strict temperature control for your specific materials.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to ensure your plastic deformation processes occur within the optimal 80-120°C window or beyond.

Ready to protect your tooling and enhance material integrity? Contact KINTEK today for a customized heating solution

Visual Guide

References

- Tamilla Khankishiyeva Tamilla Khankishiyeva, Javid Mustafayev Javid Mustafayev. INVESTIGATION OF THERMAL EFFICIENCY AND OPERATIONAL CHALLENGES IN REFINERY FURNACES. DOI: 10.36962/etm31072025-74

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of using an Annealing Furnace in gas sensors? Enhance Stability and Sensitivity

- What are the objectives of melt stirring and insulation treatment during the Al-5Er-Ti master alloy preparation process?

- How does high-precision temperature control impact the crystal growth of LaMg6Ga6S16? Precision Heating Strategies

- What features can be adjusted in laboratory furnaces based on application requirements? Optimize Your Lab's Thermal Processing

- Why is pressure molding and high-temperature sintering required for UO2-ZrO2? Mastering Material Density

- What is the function of a forced air drying oven for biochar? Optimize Moringa Oleifera Shell Pre-treatment

- What is the role of a TG-FTIR-MS coupled system in 5AT and NaIO4 analysis? Master Thermal Decomposition Insights

- What is the function of nitrogen purging during the startup phase of the pyrolysis process? Ensure Safety and Quality