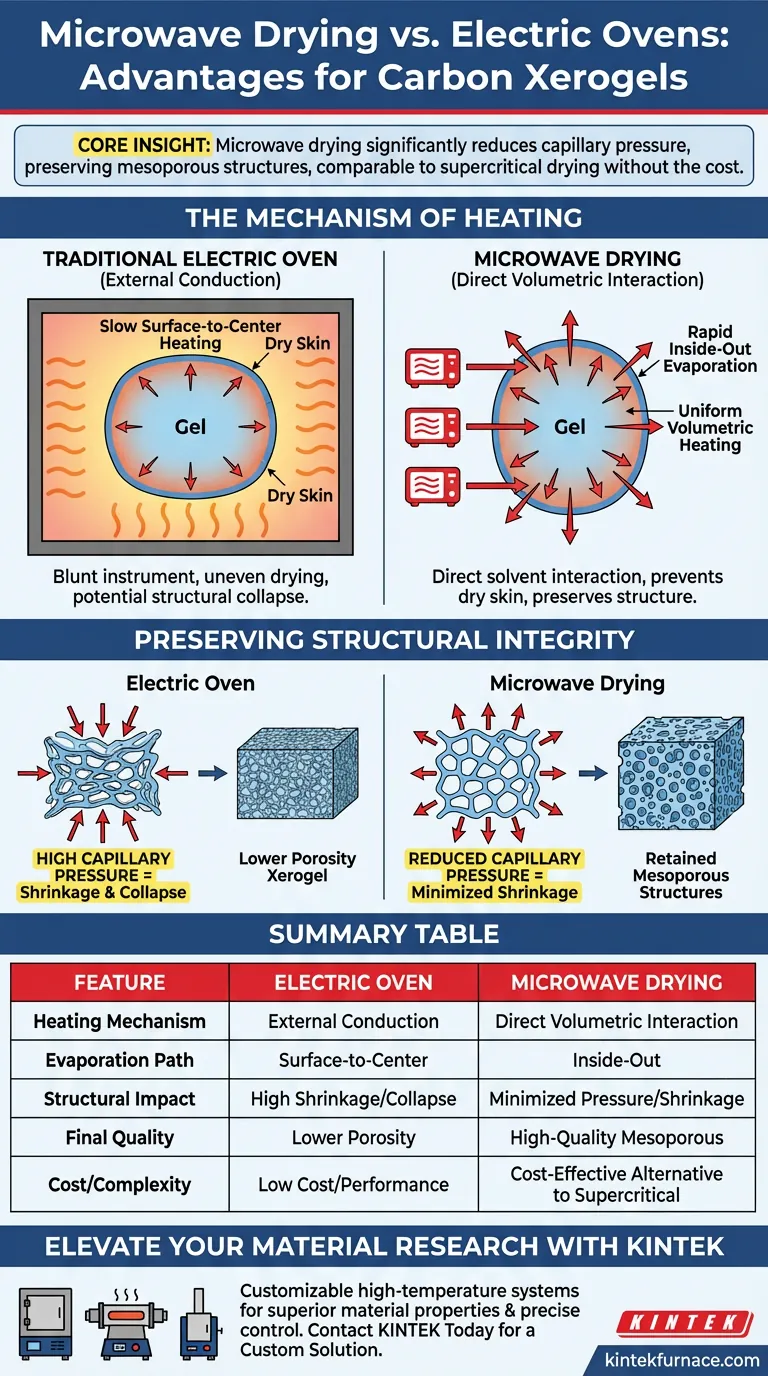

Microwave drying offers a distinct structural advantage over traditional electric heating ovens by interacting directly with the solvent molecules reside within the organic gel's pores. While electric ovens rely on external thermal conduction that can lead to uneven drying and structural collapse, microwave energy facilitates rapid evaporation from the inside out, preserving the material's critical internal architecture.

Core Insight: The superior performance of microwave drying lies in its ability to significantly reduce capillary pressure during evaporation. This preservation mechanism allows for the creation of high-quality carbon xerogels with retained mesoporous structures, achieving results comparable to supercritical drying without the associated complexity or cost.

The Mechanism of Heating

Direct Solvent Interaction

Traditional electric ovens heat the environment surrounding the gel, relying on thermal conduction to slowly warm the material from the surface inward.

In contrast, microwave drying acts directly on the solvent molecules trapped inside the gel's pores. This generates heat volumetrically rather than waiting for it to penetrate from the outside.

Inside-Out Evaporation

Because the heat is generated internally, the evaporation process occurs from the inside out.

This reversal of the traditional drying dynamic prevents the formation of a dry "skin" on the surface, which can often trap moisture and lead to internal stress in electric oven drying.

Preserving Structural Integrity

Reducing Capillary Pressure

The most critical challenge in converting organic gels to carbon xerogels is capillary pressure, which exerts immense force on the pore walls as the solvent evaporates.

Microwave drying effectively reduces this pressure. By accelerating evaporation uniformly throughout the volume, the stress placed on the pore walls is minimized.

Minimizing Shrinkage and Collapse

Under the atmospheric pressure conditions of a standard electric oven, the gel structure frequently succumbs to capillary forces, resulting in significant shrinkage and collapse.

Microwave drying mitigates this collapse. The reduction in internal stress ensures that the gel maintains its original shape and volume more effectively during the transition to a solid state.

Retention of Mesoporous Structures

The ultimate goal of this process is to create a carbon xerogel with a specific porosity.

By preventing collapse, microwave drying ensures the final product retains more of its desired mesoporous structures, which are often lost when using slower, conduction-based heating methods.

Operational and Economic Efficiency

Avoiding Supercritical Drying

Historically, avoiding pore collapse required supercritical drying, a process that eliminates surface tension entirely but is complex and expensive to operate.

Microwave drying offers a compelling alternative. It achieves sufficient structural preservation to produce high-quality xerogels without the need for high-pressure equipment or costly supercritical fluids.

Understanding the Trade-offs

The Limitations of Electric Heating

While traditional electric ovens are ubiquitous and simple to operate, they act as a blunt instrument for this specific application.

The primary trade-off of using an electric oven is a sacrifice in material quality. The external heating mechanism cannot mitigate the capillary forces that crush the delicate pore network, leading to a denser, less effective carbon material.

Process Control Requirements

While microwave drying avoids the complexity of supercritical drying, it introduces a need for precise process control.

Because the heating is rapid and volumetric, operators must ensure the microwave power is tuned correctly to prevent overheating or thermal runaway, whereas electric ovens are generally more forgiving (though less effective).

Making the Right Choice for Your Goal

To select the appropriate drying method for your organic gels, consider your specific constraints regarding cost, complexity, and material quality.

- If your primary focus is Material Quality: Choose microwave drying to maximize the retention of mesoporous structures and minimize shrinkage.

- If your primary focus is Cost Reduction: Choose microwave drying as a cost-effective alternative to expensive supercritical drying operations.

- If your primary focus is Equipment Simplicity: Acknowledge that while electric ovens are simpler, they will likely result in structural collapse and inferior porosity.

Microwave drying effectively bridges the gap between low-cost atmospheric drying and high-performance supercritical drying, offering a balanced solution for producing high-quality carbon xerogels.

Summary Table:

| Feature | Traditional Electric Oven | Microwave Drying Equipment |

|---|---|---|

| Heating Mechanism | External thermal conduction | Direct volumetric solvent interaction |

| Evaporation Path | Surface-to-center (Dry skin risk) | Inside-out (Uniform evaporation) |

| Structural Impact | High shrinkage and pore collapse | Minimized capillary pressure and shrinkage |

| Final Quality | Lower porosity carbon xerogels | High-quality retained mesoporous structures |

| Cost/Complexity | Low cost, low performance | Cost-effective alternative to supercritical drying |

Elevate Your Material Research with KINTEK

Are you struggling with structural collapse during the drying phase? Backed by expert R&D and manufacturing, KINTEK offers specialized high-temperature systems including Muffle, Tube, Rotary, Vacuum, and CVD furnaces—all fully customizable to your unique research needs.

Our advanced heating solutions empower researchers to achieve superior material properties and precise process control. Whether you are developing carbon xerogels or advanced ceramics, we provide the precision you need to succeed.

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Werner Bauer, Helmut Ehrenberg. Using Hierarchically Structured, Nanoporous Particles as Building Blocks for NCM111 Cathodes. DOI: 10.3390/nano14020134

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are some examples of low-temperature industrial heating processes? Boost Efficiency and Sustainability

- What is the purpose of using a vacuum drying oven for coated carbon cloth? Protect Substrates & Optimize Adhesion

- What are the two methods of temperature control of resistance furnace? Optimize for Precision or Cost

- What is the significance of industrial drying equipment for metal powders? Master Post-Processing & Quality Control

- What is the significance of preheating UHPC molds? Ensure Safety & Longevity with High-Temp Furnaces

- What hardware characteristics are required for a reactor system to support a three-step redox process in chemical looping?

- What is the benefit of accessing furnace technical guides? Optimize Your Research with Precise Equipment Data

- How does an industrial vacuum drying oven affect electrode performance? Optimize Sodium-Ion Battery Stability