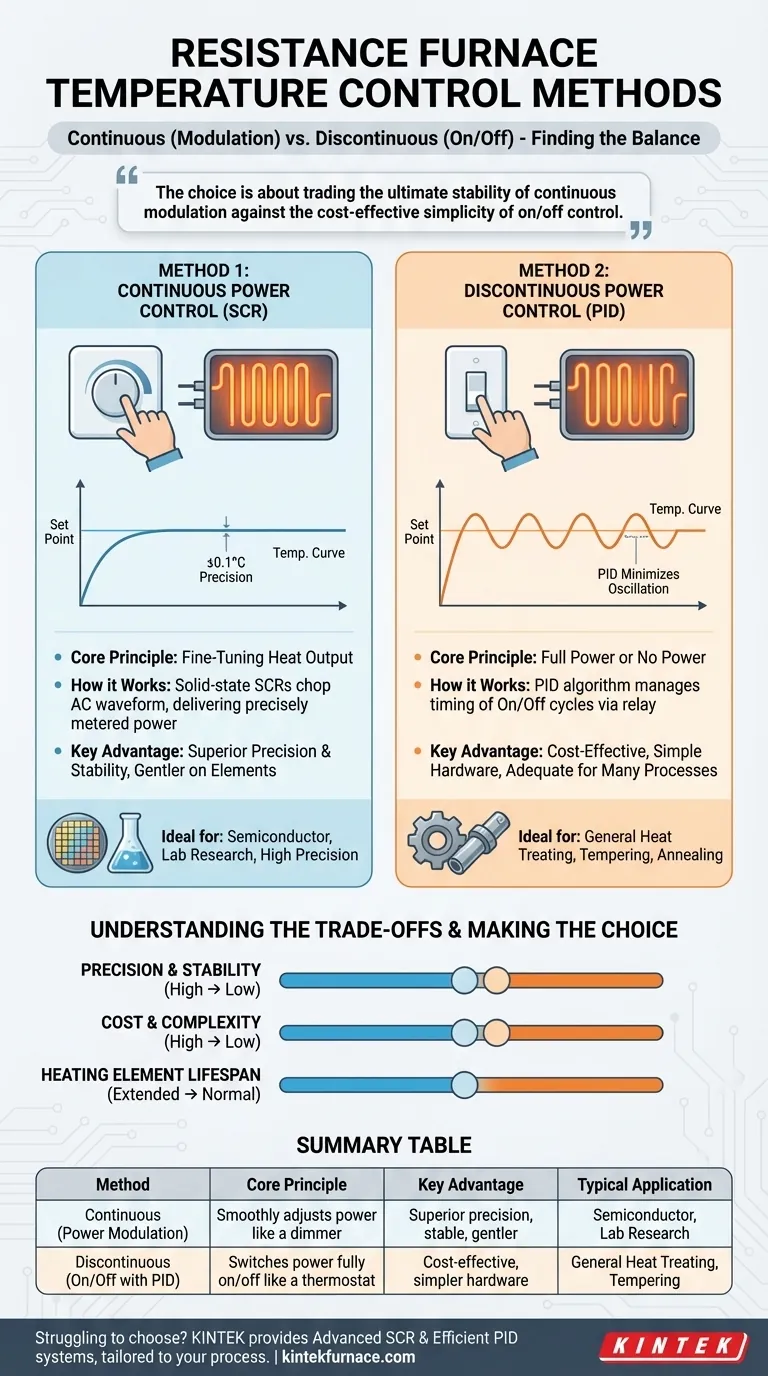

At its core, a resistance furnace's temperature is governed by two fundamental control philosophies: continuously adjusting the power level or intermittently switching the power on and off. While specific hardware varies, every control system falls into one of these two categories, each with distinct implications for precision, cost, and equipment longevity.

The choice between temperature control methods is not about which is "better," but which provides the right balance. You are trading the ultimate stability of continuous power modulation against the cost-effective simplicity of on/off control.

Method 1: Continuous Power Control (Power Modulation)

This approach works like a dimmer switch for a light bulb, smoothly and constantly adjusting the amount of electrical power delivered to the heating elements. The goal is to perfectly match the heat output to the heat loss of the furnace, creating an extremely stable equilibrium at the desired temperature.

The Core Principle: Fine-Tuning Heat Output

Instead of supplying full power or no power, this method supplies a precisely metered flow of energy. By varying the voltage or current, the controller ensures the heating elements produce just enough heat to maintain the setpoint without significant over- or undershooting.

How It's Achieved in Practice

Older systems used mechanical devices like auto-transformers or induction regulators to physically vary the voltage.

Modern furnaces almost exclusively use solid-state controllers, most notably Silicon-Controlled Rectifiers (SCRs). These electronic devices can chop up the AC power waveform, delivering a precisely controlled average power to the elements with no moving parts.

Key Advantage: Superior Precision and Stability

Because power is adjusted smoothly, the temperature curve is exceptionally flat. This method is essential for applications demanding high precision, such as semiconductor annealing or laboratory research, where temperature fluctuations of even a degree can compromise results. This is how furnaces achieve accuracies of ±1°C or even ±0.1°C.

Method 2: Discontinuous Power Control (On/Off Switching)

This is the most common and intuitive method of temperature control. It functions just like a thermostat in a home, switching the heating elements on at full power when the temperature drops below the setpoint and turning them off completely when it rises above it.

The Core Principle: Full Power or No Power

The system does not moderate the energy flow; it simply decides whether the heat is 100% on or 100% off. The furnace temperature is managed by controlling the timing and duration of these on/off cycles.

How It's Achieved in Practice

This is typically managed by a digital controller connected to a relay or contactor that switches the main power. While simple on/off control exists, most modern systems use a sophisticated algorithm called PID (Proportional-Integral-Derivative) control.

A PID controller anticipates heating needs, minimizing the temperature swings (oscillations) inherent in an on/off system for much greater stability than a basic thermostat.

The Inherent Challenge: Temperature Oscillation

By its very nature, this method causes the temperature to oscillate around the setpoint. A well-tuned PID controller can make these oscillations very small, but they can never be completely eliminated as they can with continuous control.

Understanding the Trade-offs

Choosing a control method requires understanding the technical and financial compromises involved. Your application dictates which factors are most critical.

Precision vs. Cost

Continuous (SCR) control offers the highest possible precision and stability. However, the high-power solid-state hardware is more complex and expensive than the simple relays used in on/off systems.

Discontinuous (PID) control is significantly more cost-effective and simpler to implement. For many industrial processes like basic hardening or tempering, its precision is perfectly adequate.

Impact on Heating Element Lifespan

Continuous control is gentler on heating elements. By avoiding the thermal shock of repeated full-power-on and full-power-off cycles, it can help extend the operational life of the elements.

The Critical Role of Sensors

Neither control method can function without accurate feedback. A high-precision temperature sensor, such as a thermocouple or RTD, is the "eyes" of the system. The control system's accuracy is ultimately limited by the quality and placement of its sensor.

Making the Right Choice for Your Goal

Your process requirements are the ultimate guide to selecting the appropriate control strategy.

- If your primary focus is ultimate precision and stability (e.g., semiconductor processing, lab crystal growth, advanced materials research): You require a system based on continuous power control, typically using an SCR.

- If your primary focus is general heat treating and cost-effectiveness (e.g., tempering, annealing of non-critical parts, pre-heating): A well-tuned PID-based on/off controller is the practical and economical choice.

Ultimately, effective temperature control is about matching the capability of the furnace to the demands of the process.

Summary Table:

| Control Method | Core Principle | Key Advantage | Typical Application |

|---|---|---|---|

| Continuous (Power Modulation) | Smoothly adjusts power like a dimmer switch | Superior precision (±1°C or better), stable temperature, gentler on elements | Semiconductor processing, lab research, advanced materials |

| Discontinuous (On/Off with PID) | Switches power fully on or off like a thermostat | Cost-effective, simpler hardware, adequate for many processes | General heat treating, tempering, annealing of non-critical parts |

Struggling to choose the right temperature control for your process?

Your application's demand for precision, budget, and equipment longevity dictates the ideal solution. KINTEK's expertise lies in designing high-temperature furnaces with the precise control system your work requires.

We provide:

- Advanced SCR Power Controllers for ultimate stability in research and semiconductor applications.

- Efficient PID On/Off Control Systems for cost-effective, reliable industrial heat treating.

- Deep Customization to tailor the control strategy, sensor placement, and hardware to your unique experimental requirements.

Leveraging our exceptional in-house R&D and manufacturing capabilities across our product line—including Muffle, Tube, Vacuum, and CVD Furnaces—we ensure you get a furnace that delivers exact temperature control for repeatable, successful results.

Let's optimize your thermal process. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability