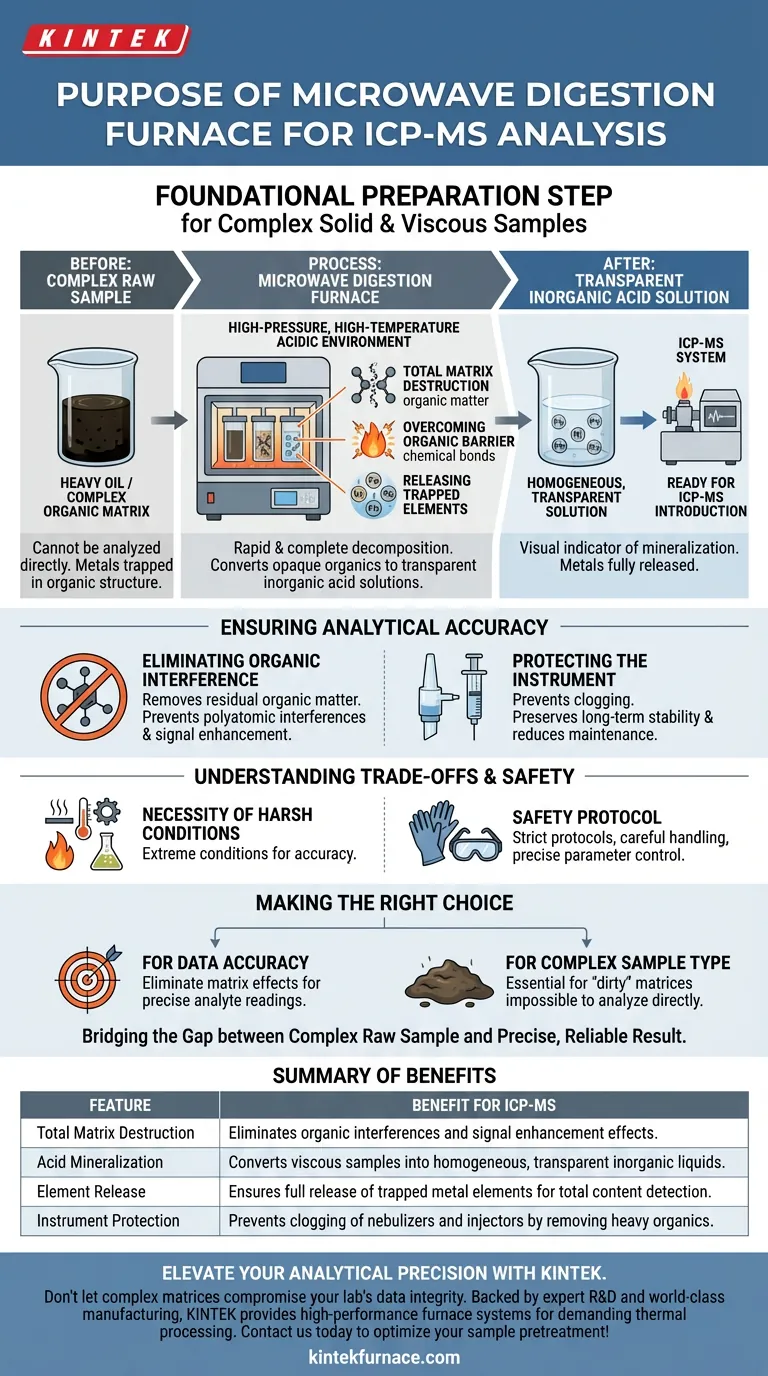

A microwave digestion furnace serves as the foundational preparation step for converting complex solid or viscous samples into a state compatible with high-sensitivity instruments. Specifically, it utilizes a high-pressure, high-temperature acidic environment to rapidly and completely decompose heavy oil organic matrices. This transforms difficult organic samples into transparent inorganic acid solutions that can be directly introduced into an Inductively Coupled Plasma Mass Spectrometry (ICP-MS) system.

The primary function of this device is total matrix destruction. It ensures that metal elements are fully released from the organic structure into the liquid phase, eliminating organic interferences that would otherwise compromise the accuracy of your trace element analysis.

The Mechanism of Decomposition

Overcoming the Organic Barrier

Samples such as heavy oils possess complex organic matrices that cannot be analyzed directly. The microwave digestion furnace applies intense thermal energy and pressure to these matrices. This harsh environment breaks the strong chemical bonds holding the organic matter together.

Creating a Homogeneous Solution

The result of this process is a physical transformation of the sample. The furnace converts the opaque, viscous organic material into a transparent inorganic acid solution. This clarity is the visual indicator that the organic components have been successfully mineralized.

Releasing Trapped Elements

Metal elements are often bound tightly within the organic structure of the sample. By completely decomposing the matrix, the furnace ensures these metals are fully released into the liquid phase. This guarantees that the subsequent analysis detects the total metal content, not just a fraction of it.

Ensuring Analytical Accuracy

Eliminating Organic Interference

One of the greatest threats to ICP-MS accuracy is interference from residual organic matter. If organic carbon remains in the sample, it can cause polyatomic interferences or signal enhancement effects. The digestion furnace removes this variable by destroying the organic matter before it ever reaches the instrument.

Protecting the Instrument

Injecting heavy organics directly into an ICP-MS would quickly clog the nebulizer and injector. By converting the sample into a thin, inorganic acid solution, the furnace protects the delicate sample introduction system. This preserves the instrument's long-term stability and reduces maintenance downtime.

Understanding the Trade-offs

The Necessity of Harsh Conditions

To achieve the "transparent solution" required for accuracy, the furnace must operate under extreme conditions. This involves the use of concentrated acids combined with high heat and pressure.

Safety and Protocol

Because the environment inside the digestion vessels is so aggressive, strict safety protocols are non-negotiable. While the process guarantees the best analytical results, it requires careful handling of vessels and precise control of temperature and pressure parameters to prevent venting or vessel failure.

Making the Right Choice for Your Goal

When evaluating the role of microwave digestion in your workflow, consider your specific analytical objectives:

- If your primary focus is Data Accuracy: Rely on digestion to completely eliminate organic matrix effects, ensuring your ICP-MS reads only the target analytes.

- If your primary focus is Sample Type: Use this method specifically for "dirty" or complex matrices (like heavy oil) that are impossible to analyze without prior decomposition.

Ultimately, the microwave digestion furnace bridges the gap between a complex raw sample and a precise, reliable result.

Summary Table:

| Feature | Benefit for ICP-MS Analysis |

|---|---|

| Total Matrix Destruction | Eliminates organic interferences and signal enhancement effects. |

| Acid Mineralization | Converts viscous samples into homogeneous, transparent inorganic liquids. |

| Element Release | Ensures full release of trapped metal elements for total content detection. |

| Instrument Protection | Prevents clogging of nebulizers and injectors by removing heavy organics. |

Elevate Your Analytical Precision with KINTEK

Don't let complex matrices compromise your lab's data integrity. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance furnace systems—including Muffle, Tube, and Vacuum furnaces—tailored to meet the most demanding thermal processing and sample preparation needs. Whether you require a standard system or a customized solution for unique lab workflows, our team is ready to help you achieve consistent, reliable results.

Ready to optimize your sample pretreatment? Contact us today to discuss your application requirements with our technical experts!

Visual Guide

References

- Influence of Oil-Soluble Catalyst on Composition and Structure of Heavy Oil from Samara Region Field. DOI: 10.3390/chemengineering9010011

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What experimental conditions does a high-temperature continuous flow fixed-bed reactor provide for Zn-Cr catalysts?

- What are the functions of an industrial drying furnace vertically installed below a shredder? Efficient LIB Recycling

- What is the primary function of a forced air oven in SnmCunOx-t synthesis? Master Chemical Foaming

- How are magnetic stirrers and constant temperature drying ovens utilized in the wet chemical synthesis of copper selenide nanorods?

- Why is substrate preheating typically employed during the LPBF process? Minimize Stress & Prevent Cracks in 3D Printing

- What is the role of a high-temperature stainless steel autoclave in the synthesis of Copper Ferrite (CuFe2O4)?

- Why is a high-precision constant temperature drying oven required for biochar? Protect Delicate Pore Structures

- Why is high-purity argon gas required for MTO synthesis? Ensure Stability in Rhenium Organometallic Catalysis