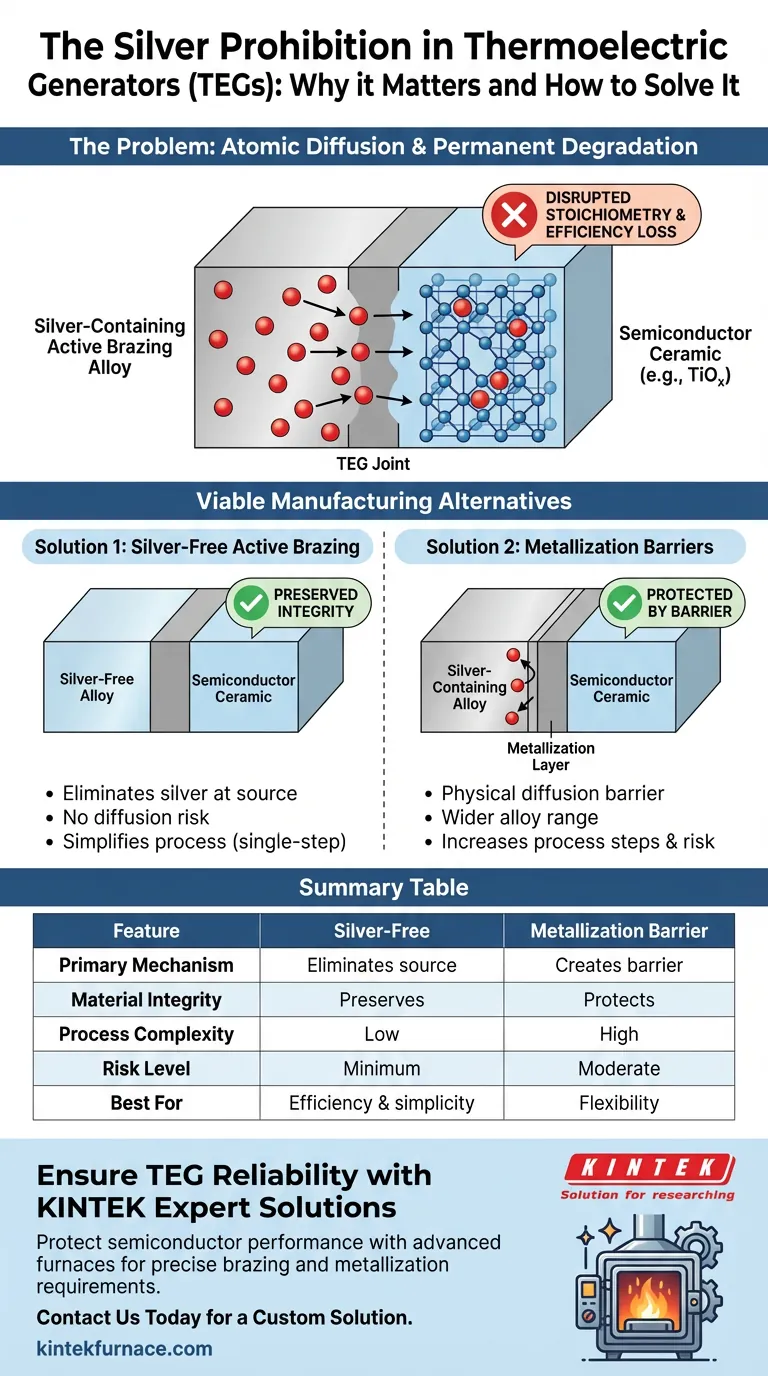

The prohibition of silver-containing alloys is driven by atomic diffusion. When used in Thermoelectric Generators (TEGs), silver atoms from the active brazing alloy penetrate the semiconductor ceramic material, such as titanium oxides (TiOx). This migration disrupts the material's internal structure, leading to a breakdown in semiconductor performance and a critical loss of efficiency.

Core Takeaway Silver acts as a contaminant in TEG ceramics, altering the electrical stoichiometry essential for energy conversion. To prevent permanent degradation, manufacturers must utilize silver-free alloys or apply distinct metallization barriers.

The Mechanism of Failure

The Threat of Diffusion

The core issue is the mobility of silver atoms. During the brazing process or subsequent operation, these atoms do not remain confined to the joint interface. Instead, they diffuse directly into the bulk of the semiconductor ceramic.

Disruption of Electrical Stoichiometry

Thermoelectric materials rely on a precise chemical balance, known as stoichiometry, to function. When silver infiltrates the lattice of materials like TiOx, it acts as an impurity. This alters the electrical properties of the ceramic, effectively neutralizing the specific semiconductor characteristics required to generate electricity from heat.

Irreversible Efficiency Loss

The presence of silver is not a temporary interference; it causes permanent degradation. As the semiconductor properties deteriorate, the TEG loses its ability to convert thermal gradients into electrical energy efficiently, rendering the device ineffective over time.

Viable Manufacturing Alternatives

Silver-Free Active Brazing

The most direct solution is the elimination of the containment source. By selecting silver-free active brazing alloys, manufacturers remove the risk of diffusion entirely. This approach preserves the chemical integrity of the semiconductor ceramic without requiring additional protective steps.

Metallization Barriers

If a silver-free alloy is not utilized, the ceramic surface must be modified. This involves applying a metallization layer before brazing. This layer acts as a physical diffusion barrier, preventing silver atoms from contacting and penetrating the sensitive semiconductor material.

Understanding the Trade-offs

Process Simplicity vs. Component Design

Choosing between these solutions involves a trade-off in manufacturing complexity. Using silver-free alloys simplifies the process by removing the need for barrier layers, but it limits your selection of brazing materials.

Risk Management

Relying on a metallization layer allows for a broader range of brazing alloys but introduces a potential single point of failure. If the barrier layer is imperfect or damaged during assembly, silver diffusion will occur, leading to the same degradation mechanism described above.

Making the Right Choice for Your Goal

To ensure the longevity and efficiency of your Thermoelectric Generators, you must select a joining strategy that aligns with your specific material constraints.

- If your primary focus is process efficiency: Prioritize the use of silver-free active brazing alloys to eliminate the need for complex barrier deposition steps.

- If your primary focus is material flexibility: Implement a robust metallization layer to act as a diffusion barrier, allowing the use of standard silver-containing alloys without compromising the ceramic.

Ultimately, protecting the electrical stoichiometry of the semiconductor is the single most critical factor in TEG assembly reliability.

Summary Table:

| Feature | Silver-Free Active Brazing | Metallization Barriers |

|---|---|---|

| Primary Mechanism | Eliminates silver at the source | Creates a physical barrier layer |

| Material Integrity | Preserves ceramic stoichiometry | Protects ceramic from silver atoms |

| Process Complexity | Low (single-step joining) | High (requires pre-metallization) |

| Risk Level | Minimum (no diffusion possible) | Moderate (failure if barrier is thin) |

| Best For | Process efficiency & simplicity | Using a broader range of alloys |

Ensure TEG Reliability with KINTEK Expert Solutions

Protect your semiconductor performance from the risks of atomic diffusion. KINTEK provides the advanced equipment and material expertise necessary for high-precision Thermoelectric Generator manufacturing. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique brazing and metallization requirements.

Don't let silver contamination compromise your efficiency. Partner with KINTEK for reliable, high-performance thermal processing solutions.

Contact Us Today for a Custom Solution

Visual Guide

References

- Jian Feng, Antonio Hurtado. Active Brazing for Energy Devices Sealing. DOI: 10.3390/jeta2010001

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is niobium foil wrapped around niobium cavity flanges? Protect Your UHV Seals During Heat Treatment

- Why is a constant temperature blast drying oven necessary for biomass carbon impregnation? Optimize Material Structure

- What is the primary role of an industrial-grade oven in the preparation of chitosan-modified soil samples?

- What is the role of high-vacuum sealing technology? Precision Synthesis of High-Performance Copper Sulfide

- What is the primary function of a drying oven in the preparation of calcium oxide from eggshell waste? Maximize Purity

- What are the advantages of PVD coating? Achieve Precision, Purity, and Eco-Friendly Performance

- Why is a precision constant temperature drying oven required for the impregnation modification process of activated carbon?

- What role does a laboratory facility play in establishing the mass balance for a coke oven operation? Drive Efficiency.