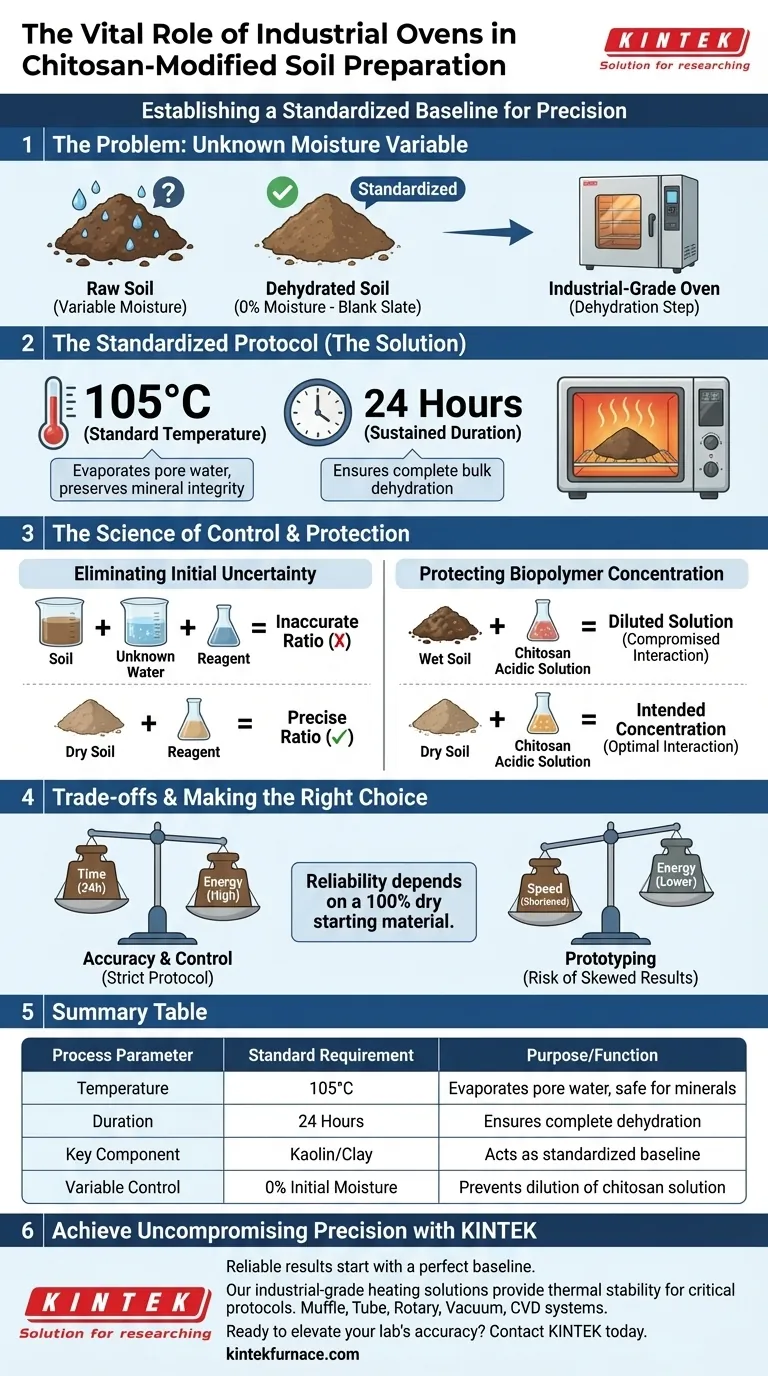

The primary function of an industrial-grade oven in preparing chitosan-modified soil is to establish a standardized baseline by completely dehydrating raw materials. Specifically, it dries components like high-plasticity kaolin at 105 °C for 24 hours to eliminate any pre-existing moisture. This step is critical because it removes the variable of unknown water content before the mixing process begins.

Precise experimental control requires starting with a "blank slate." By using an oven to ensure the raw soil is completely dry, you guarantee that the final moisture content and biopolymer concentration are determined solely by your added solution, not by environmental humidity or storage conditions.

The Science of Baseline Control

Eliminating Initial Uncertainty

Raw soil samples naturally hold varying amounts of water depending on storage conditions and humidity. If you mix reagents into soil that already contains moisture, your calculations regarding the total water-to-solids ratio will be incorrect.

Protecting Biopolymer Concentration

In these preparations, a specific chitosan acidic solution is added to the soil to modify its properties. If the soil is not pre-dried, the existing pore water will dilute this acidic solution.

This dilution alters the intended concentration of the biopolymer, potentially compromising the chemical interaction between the chitosan and the soil particles.

The Standardized Dehydration Protocol

The Temperature Standard

The industry standard for this process is maintaining the oven at 105 °C. This temperature is high enough to evaporate pore water efficiently but generally safe for the mineral integrity of clays like kaolin.

Duration for Equilibrium

The process requires a sustained duration, typically 24 hours. This ensures that the heat penetrates the bulk of the material and that moisture removal is not just superficial, but complete.

Understanding the Trade-offs

Time Efficiency vs. Accuracy

The primary trade-off in this process is time. Adding a 24-hour drying cycle significantly extends the preparation timeline for samples.

Energy Consumption

Running industrial-grade heating elements for a full day is energy-intensive. While necessary for high-precision research, it represents a resource cost that must be factored into the operational workflow.

Making the Right Choice for Your Goal

To ensure your chitosan-modified soil samples are prepared correctly, consider your specific accuracy requirements:

- If your primary focus is strict experimental control: You must adhere to the 24-hour drying protocol at 105 °C to ensure the biopolymer concentration is exact.

- If your primary focus is rough prototyping: You might be tempted to shorten this time, but recognize that any residual moisture will skew your final material properties and make replication impossible.

The reliability of your entire experiment depends on the certainty that your starting material is 100% dry.

Summary Table:

| Process Parameter | Standard Requirement | Purpose/Function |

|---|---|---|

| Temperature | 105 °C | Evaporates pore water without damaging mineral integrity |

| Duration | 24 Hours | Ensures complete dehydration through the bulk of material |

| Key Component | Kaolin/Clay | Acts as the standardized baseline material |

| Variable Control | 0% Initial Moisture | Prevents dilution of the chitosan acidic solution |

Achieve Uncompromising Precision in Your Material Science Research

At KINTEK, we understand that reliable experimental results start with a perfect baseline. Whether you are modifying soil with biopolymers or conducting advanced material synthesis, our industrial-grade heating solutions provide the thermal stability and uniformity required for critical dehydration protocols.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all customizable to meet your unique research needs. Don't let residual moisture or temperature fluctuations compromise your biopolymer concentrations.

Ready to elevate your lab's accuracy? Contact KINTEK today to find the perfect furnace solution for your application.

Visual Guide

References

- Runshen Wang, Tingting Yao. Optimizing Soil Stabilization with Chitosan: Investigating Acid Concentration, Temperature, and Long-Term Strength. DOI: 10.3390/polym17020151

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the equipment requirements for o-LISO ceramic sintering? Achieve 1050°C Precision for High Conductivity

- What are the typical functions performed by laboratory furnaces? Unlock Precise Thermal Processing for Your Materials

- Why are DEZ and GEME selected for Ge:ZnO ALD? Unlock Precise Atomic Doping and Thermal Stability

- What are the applications of heat treatment furnaces in the aerospace industry? Enhance Component Performance for Extreme Conditions

- Why is the purity of oxide precursors critical for ZnO-doped CuO? Ensure High Photocatalytic Performance

- What are the applications of sintering furnaces in 3D printing? Unlock High-Strength Parts for Aerospace and More

- Why is a homogeneous reactor used for crystallization? Achieve 100% Thermal Uniformity for Pure Crystals

- What is the purpose of the sulfidation treatment process? Enhance Reactor Performance with DMDS Passivation