In 3D printing, sintering furnaces are essential post-processing tools used to transform fragile, powder-based parts into dense, high-strength final components. Their primary applications are the sintering of metal parts for industries like aerospace and automotive, and the sintering of technical ceramics for high-temperature and wear-resistant applications.

A 3D printer in a powder-based process creates the part's shape, but the sintering furnace is what gives the part its final strength and density. It completes the manufacturing process by thermally fusing the powder particles into a solid, functional object under highly controlled conditions.

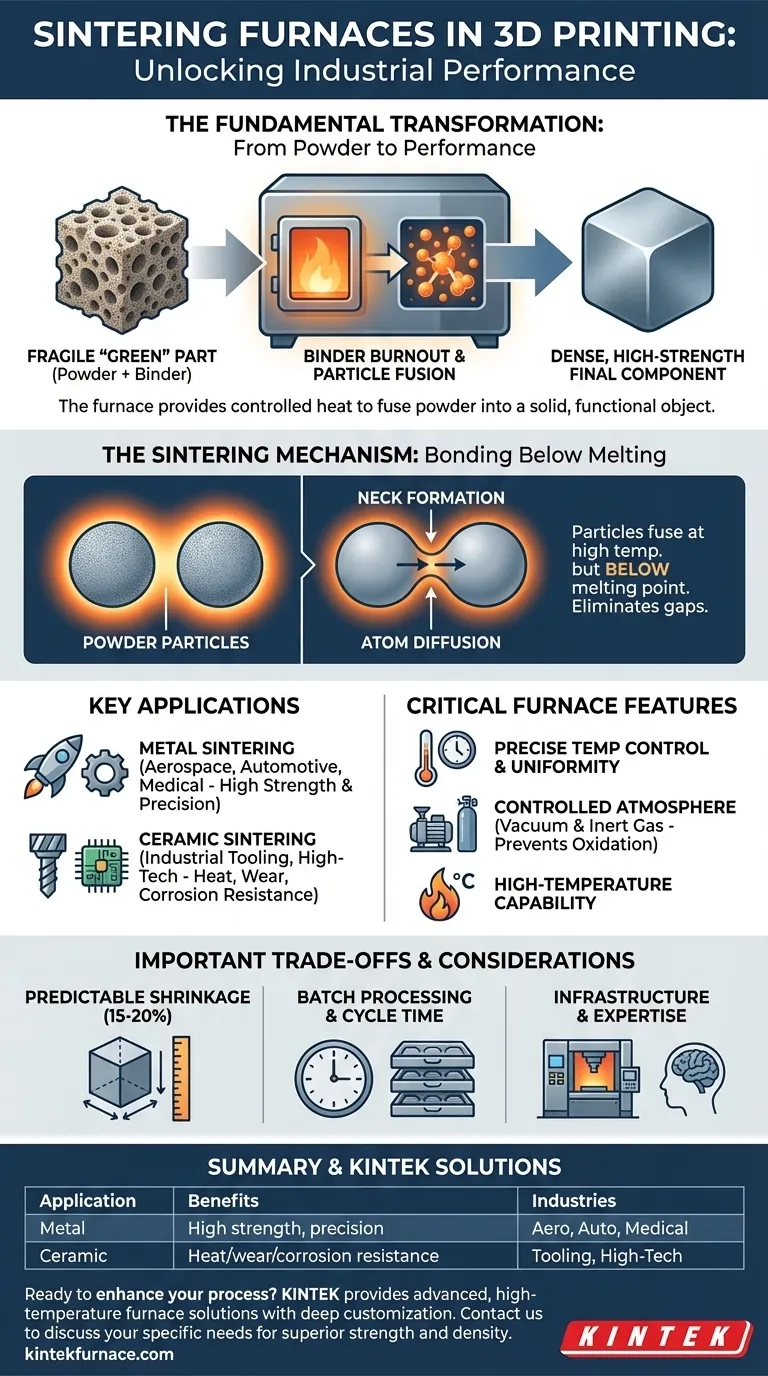

The Fundamental Role: From Powder to Performance

Sintering is a thermal treatment process that is a critical, and often misunderstood, step in certain additive manufacturing workflows, most notably metal binder jetting.

From "Green" Part to Final Component

After a part is printed using a technology like binder jetting, it exists in a fragile "green" state. It is composed of metal or ceramic powder held together by a polymer binding agent.

The part has its final shape but possesses very little mechanical strength. The sintering furnace is responsible for burning out this binder and then heating the remaining powder to fuse it into a fully dense, solid part.

The Sintering Mechanism: Bonding Below Melting

Sintering heats a component to a high temperature, but crucially, below the material's melting point.

At this elevated temperature, the atoms in the powder particles diffuse across the boundaries of adjacent particles, causing them to fuse together. This process eliminates the gaps between particles, resulting in a dense, solid component with properties similar to one made via traditional manufacturing.

Key Applications in Additive Manufacturing

Sintering furnaces enable the use of 3D printing for demanding industrial applications where material performance is non-negotiable.

Metal Sintering for Industrial Production

This is the most common application. Furnaces are used to create dense metal parts from materials like stainless steel, tool steel, and superalloys. These components are used in the aerospace, automotive, and medical industries for complex geometries that require high strength and precision.

Ceramic Sintering for Extreme Environments

3D printing can also create complex ceramic parts. A sintering furnace provides the extremely high temperatures needed to fuse ceramic powders into a final part that is highly resistant to heat, wear, and corrosion, making them ideal for specialized industrial tooling and components.

Critical Furnace Features for 3D Printing

Not just any oven will work. Furnaces designed for 3D printing post-processing have specific features essential for producing high-quality parts.

Precise Temperature Control & Uniformity

The furnace must maintain a highly uniform temperature throughout its chamber. Any significant variation can cause uneven shrinkage or warping, leading to a failed part. Precise control of the heating and cooling rates is also critical to manage internal stresses.

Controlled Atmosphere (Vacuum & Inert Gas)

Heating metal powder in the presence of oxygen causes oxidation, which contaminates the material and severely degrades its mechanical properties. Sintering furnaces use a vacuum or an inert gas atmosphere (like argon) to eliminate oxygen and ensure a pure, strong final part.

High-Temperature Capability

Advanced engineering materials require very high temperatures to sinter properly. A furnace must be able to safely and consistently reach the required temperature for the specific metal or ceramic alloy being processed.

Understanding the Trade-offs

While powerful, a sintering-based workflow involves important considerations that must be factored into the design and production process.

Predictable Part Shrinkage

As the voids between powder particles are eliminated during sintering, the part will shrink. This shrinkage is significant (often 15-20%) but is also highly predictable. Designs must be scaled up accordingly in the initial CAD phase to compensate for this effect and achieve the correct final dimensions.

Batch Processing and Cycle Time

Sintering is a batch process, not a continuous one. A full furnace cycle, including heating, holding at temperature, and cooling, can take many hours or even days. This time must be factored into the total production lead time for a component.

Infrastructure and Expertise

High-temperature vacuum furnaces are significant pieces of industrial equipment. They represent a major capital investment and require specialized knowledge for safe and effective operation and maintenance.

Making the Right Choice for Your Goal

Integrating a sintering furnace is a strategic decision that depends entirely on your manufacturing objective.

- If your primary focus is producing complex metal parts at scale: A binder jetting and sintering workflow is a leading solution for achieving high throughput.

- If your primary focus is creating parts for high-temperature or extreme-wear environments: A ceramic 3D printing process followed by furnace sintering is often the only viable manufacturing method.

- If your primary focus is rapid prototyping of one-off metal parts: Direct melting processes like DMLS or SLM, which combine printing and fusion in one step, may be a more direct route.

Ultimately, the sintering furnace is the key that unlocks the full industrial potential of powder-based additive manufacturing technologies.

Summary Table:

| Application | Key Benefits | Common Industries |

|---|---|---|

| Metal Sintering | High strength, precision, dense parts | Aerospace, Automotive, Medical |

| Ceramic Sintering | Heat/wear/corrosion resistance, complex shapes | Industrial Tooling, High-Tech Components |

Ready to enhance your 3D printing process with reliable sintering solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our sintering furnaces can deliver superior strength and density for your metal or ceramic parts!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab